Back in the day, if you popped the hood and caught a glimpse of a set of Corvette script valve covers, a dual four-barrel carb setup or heaven forbid, a Corvette Ramjet Fuel Injection system, you just knew this car was hot (sizzling hot, if it was fuel injected). The pinnacle of Chevy’s power has almost always been found under the hood of a Corvette. It was typically the platform to debut the most potent of engine combinations (although there were exceptions – the 1970 LS6 comes to mind).

Following the Corvette lead, some of the engines would then be shared with other platforms. In their day, many engines were considered super stout and very exclusive. In fact, Corvettes weren’t that common back then. In some cases, the Corvette engines forged ahead of other Detroit brands in terms of technology and horsepower. Chevrolet (and Corvette in particular) was on a roll.

That’s why having a “Vette engine” in your car really meant something. They were legendary. And with that thought in mind, follow along as we present a series featuring some of the best vintage firepower to ever come out of Detroit.

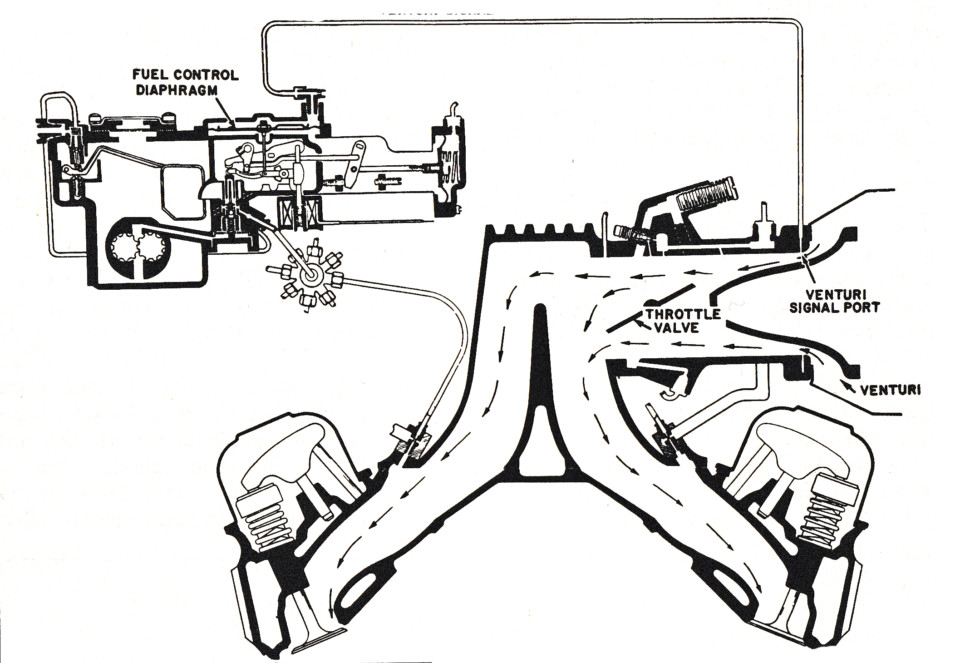

This illustration from a 1960 vintage Chevrolet service publication (1956-1960 Corvette Chassis Service Operations) shows the basics of mechanical fuel injection. The fuel meter is shown at the top left and the partial fuel distributor is shown below it. The distributor routes high-pressure fuel to each intake port. Meanwhile, the air-meter is shown as one-piece with the air-plenum, but it was actually bolted on.

The Early Fuelies

While Zora Arkus-Duntov didn’t invent the Corvette, he surely was the man who put it on the map as a real sports car. By the 1956 model year, Duntov was firmly in control of Corvette’s fortunes, and it certainly shows with the arrival of the 1957 model. The collaboration between Chevrolet (most likely with Duntov’s prodding) and the folks at the Rochester Division on a special fuel-injection project resulted in a milestone combination for the bow-tie division – a one-horsepower-per-cubic-inch, small-block V-8. Chevy wasn’t the first on the Detroit block to reach such a momentous plateau, that accolade belonged to Chrysler with their 355-horsepower, 354-cubic-inch Hemi for 1956. Even so, Corvette’s 283/283 is a remarkable powerplant and perhaps one of the most influential of all time.

Chevrolet produced 1,040 fuel-injected cars in the engine’s debut year, 284 were hydraulic-lifter equipped and 756 were high-horsepower models, using mechanical lifters. Of which, 713 RPO 579 “B” series Corvettes and 43 RPO 579 “E” series Corvettes were built in 1957. What’s the difference between them? The “E” series examples were hailed as “airbox” cars. These Corvettes were constructed with a special cold-air intake arrangement and included a column-mounted tachometer, along with other special race hardware.

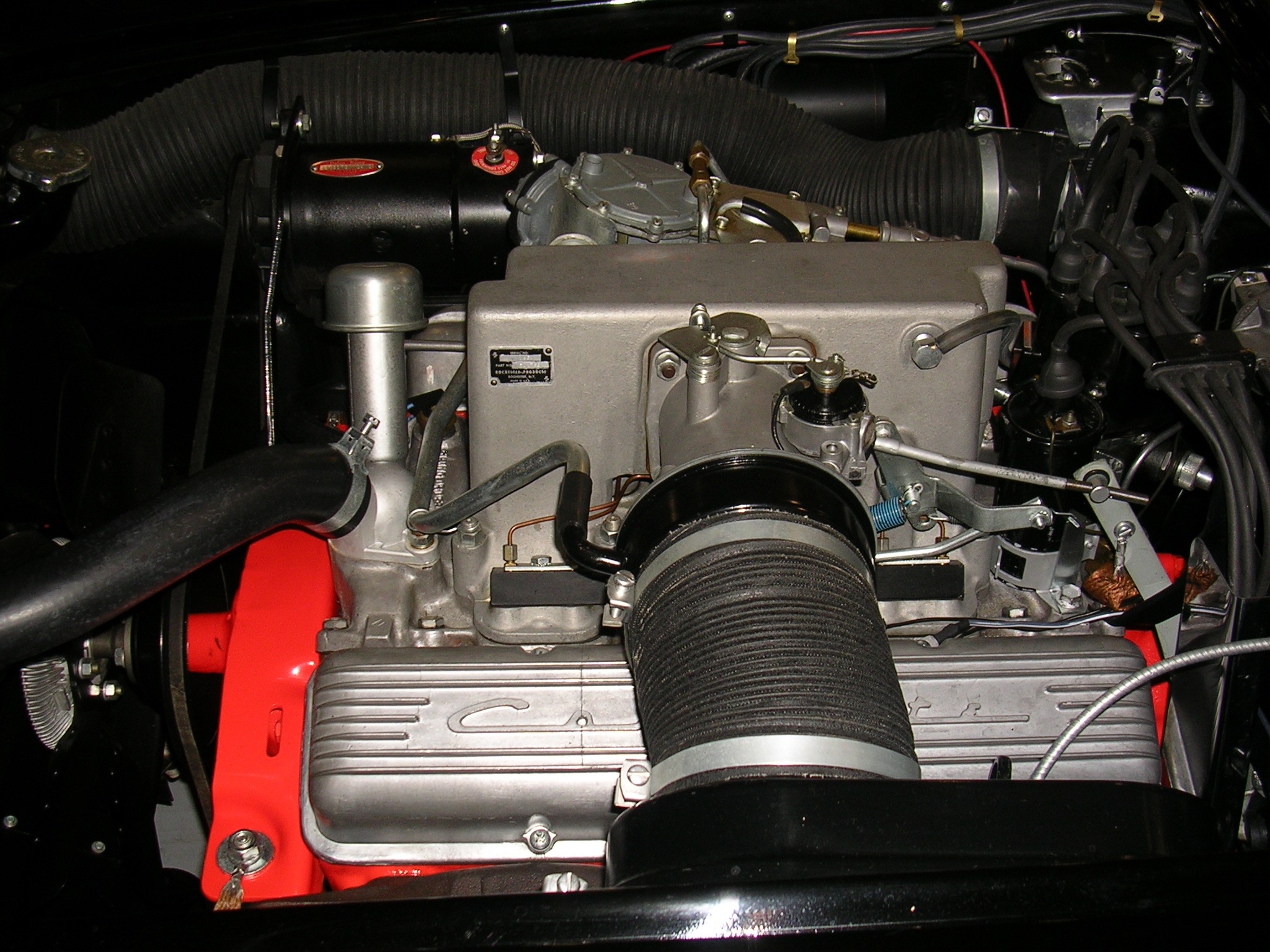

Look closely at this first-model-year fuelie and you can see the tachometer was actually driven off the back of the generator. You can see the mechanical-tach-drive cable routed from the generator through the firewall.

In 1958, 1,007 high-horsepower (now 290 hp), fuel-injected Corvettes were built. In the 1959 model year, the number of high-horsepower, solid-lifter fuelies dwindled to 920 examples. By the 1960 model year, a new aluminum head 283 fuel-injection engine was planned, but due to production difficulties, none were built with the lightweight heads. Instead, 759 iron head, high-horsepower (315) fuel-injected Corvettes were manufactured. In 1961, the final year of 283ci small-block Corvette production, there were 1,462 examples assembled with 315 hp.

Not so surprising was the cost. The base price for a 1957 Corvette was $3,176.32. Option 579B for the 283/283 would set you back a considerable $484.20. Selecting the airbox option 283/283 raised the buy-in to a whopping $726.30! In today’s dollars, the base Corvette works out to a reasonable $28,398. Meanwhile, the pair of high-horse, fuel-injected 283s works out to $4,329.08 and $6,493.61 respectively, in today’s dollars! Not exactly chump change when you do the math.

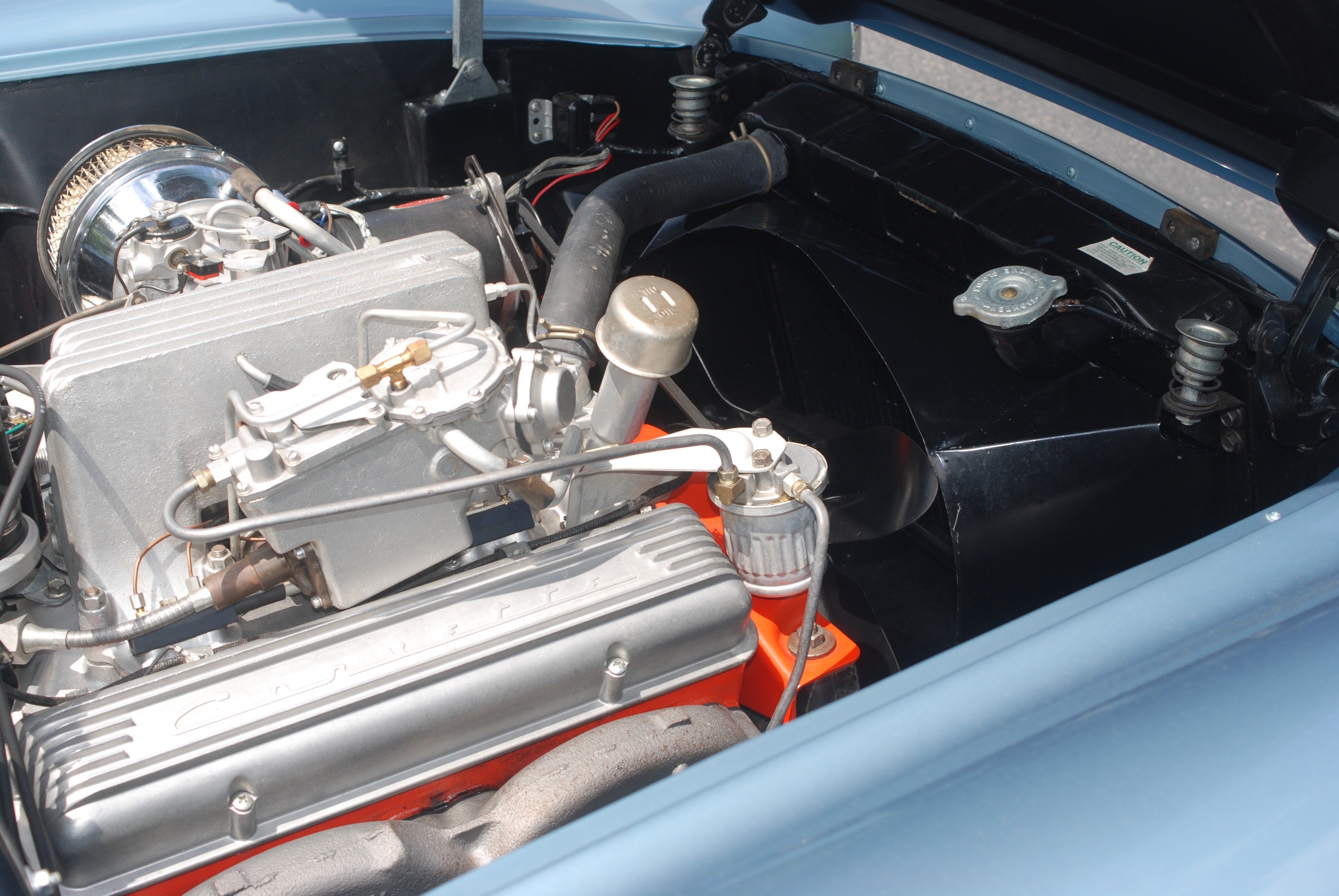

The fiberglass panel you see on the inner fender of this Corvette is the “airbox.” Airbox fuelies were special because cold air was forced directly into the entrance of the air-meter. Compare this setup to the open-element air cleaner shown in the next photo.

Performance Packaging

In terms of build specifications, all of these top-of-the-heap 283/283 engines incorporated a compression ratio of 10:1 (and higher). The slipper-skirt pistons were forged aluminum, three-ring designs. The crankshaft was forged steel, with a stroke of 3.00 inches. The main-bearing diameter was specified as 2.2978 to 2.2988 inches while the crank pins measured 1.999 to 2.000 inches. Connecting rods were forged steel and typical for all small-blocks, had a center-to-center length of 5.7 inches.

283/283 Specifications (1957 High-Performance FI Engine)

Type: Eight-cylinder, 90-degree overhead valve

Displacement: 283ci

Cylinder Bore: 3.8745 by 3.8755 inches

Crankshaft Stroke: 3.00 ± .005 inches

Advertised Compression Ratio: 10.00:1

Brake Horsepower, Advertised: 283 @ 6,200 rpm

Maximum Torque: 290 lb-ft @ 4,400 rpm

Valve Lifters: Rochester Ramjet fuel-injection

Fuel: Super Premium

Exhaust: Dual

Cylinder Block Material: Cast Iron

Cylinder Head Material: Cast Iron

Crankshaft: Steel Forging

Main Bearing Diameter: 2.2978 to 2.2988 inches

Thrust Bearing: Number 5

Crankpin Bearing Diameter: 1.999 to 2.000 inches

Connecting Rod Type: Forged Steel with separate caps

Connecting Rod Length, Center-to-Center: 5.700 inches

Piston Type: Forged Aluminum, slipper skirt

Piston Pin Type: Tubular chromium steel

Piston Pin Diameter: 0.9270 to 0.9273 inches

Piston Pin Length: 2.990 to 3.010 inches

Piston Pin Bushing Type: None

Compression Piston Ring Type: Cast Iron Alloy, flash chrome

Second Piston Ring Type: Cast Ductile Iron

Oil Piston Ring Type: Chrome Steel Rails, One Stainless Steel Expander

Camshaft Material: Precision-Molded, Special Alloy

Valve lift, Theoretical Intake: 0.3938 inch

Valve Lift, Theoretical Exhaust: 0.3998 inch

Operating Tappet Clearance: 0.012 inch Int. — 0.018 inch Exh.

Intake Valve Timing: Opens 35-degrees BTDC, Closes 72-degrees ABDC

Exhaust Valve Timing: Opens 76-degrees BBDC, Closes 31-degrees ATDC

Camshaft Drive Type: Link Belt Timing Chain

Intake Valve Type: Special Alloy Steel w/ Aluminum Face Coating

Overall Valve Length, Intake: 4.9089 inches

Overall Head Diameter, Intake: 1.720 inches

Angle of Seat & Face: 46 to 45 degrees

Exhaust Valve Type: High-Alloy Steel w/Aluminum Face Coating

Overall Valve Length, Exhaust: 4.9230 inches

Overall Head Diameter, Exhaust: 1.500 inches

Angle of Seat & Face: 46 to 45 degrees

Initial Ignition Timing: 4-degrees BTDC

Firing Order: 1-8-4-3-6-5-7-2

By 1958, the big-power 283s reached 290 hp. That engine setup continued into 1959, but by 1960 the most potent 283 offered by Chevrolet was this version. It’s (obviously) a Rochester mechanical fuel-injected combination that produces 315 horsepower.

When it came to valvetrain, the camshafts were solid-lifter jobs, with lift specs (for the ’57 model year) of 0.398 inch. The operating lash was 0.012 inch and 0.018 inch for the intake and exhaust valves, respectively. Intake valve timing saw the valve open at 35-degrees BTDC and close at 72-degrees ABDC. Meanwhile, the exhaust timing events saw the valve open at 76-degrees BBDC and close at 31-degrees ATDC. Intake valves in 1957 measured 1.72 inches across the face; exhaust valves measured 1.50 inches across the face. The camshaft was driven off of the crank by way of a link-belt timing chain. It operated the valves by way of Chevy’s relatively new, stamped-steel rocker arm arrangement.

The air meter is the device bolted to the driver’s side of the intake manifold plenum. The main purpose of the air meter is to measure, control and, along with the plenum, deliver the air required for the combustion process. With the air cleaner removed from this fuelie (left), you can see the air meter “diffuser cone” and “venturi ring” combination. The diffuser cone and the venturi ring were removed first (after the fuel idle and air adjusting screws were removed) when servicing the air meter. The air meter was a simple device with few service parts.

A "General" View Of Fuel Injection

Upstairs, all the high-horsepower 283s were equipped with a Rochester “Ramjet” fuel-injection assembly. It was a unique assembly, one that history has shown to be well ahead of its time. Included next is an excerpt from vintage Chevrolet dealer material which does a good job of describing the benefits and basic functions of the Ramjet system. Check it out:

“Chevrolet Ramjet Fuel Injection is an entirely new, highly efficient system for supplying a precisely controlled air and fuel mixture to each cylinder of the engine. Among its advantages are faster response to the accelerator and a resulting sense of greater smoothness, both during engine warm-up and under normal operating conditions. Starting is quick and positive, even in severe weather, and smoother idling and low speed operation, together with greater overall fuel economy, is obtained.

Carburetors and their various disadvantages are eliminated. For instance, fuel atomized by air passing through the carburetor venturi, is carried all the way from the carburetor, through the intake manifold to the intake ports at each cylinder. This makes it necessary to provide intake manifold passages large enough for easy breathing, but small enough to maintain adequate airflow velocity at idle, so that the fuel will not settle out and upset the proper mixture ratio. Furthermore, carburetors must be heated to help vaporize the gasoline and help atomize the fuel. Heat is also used to prevent the formation of ice in the carburetor air-fuel passage on cold starts. This is due to the refrigeration action of the carburetor venturi and the atomization of the fuel. The heat required expands the incoming air, making it less dense, causing loss of power.

On the other hand, the Chevrolet Ramjet fuel injection system supplies fuel under pressure right up to the cylinder head intake ports through individual fuel lines. Separate passages are also provided to supply clean air, unencumbered by gasoline vapors, all the way to each individual cylinder head intake port. Here the fuel, finely atomized by the injection nozzles, mixes thoroughly with the fast-moving air and is drawn into each combustion chamber, thus providing precise and uniform cylinder-to-cylinder distribution. Because fuel is vaporized at the cylinder head intake ports, and the incoming air does not pass through a venturi of the carburetor where refrigerating action takes place, the induction system does not require heat to prevent icing. As a result, the incoming air is not subjected to external heat and a larger quantity of air is drawn into the combustion chamber. Volumetric efficiency is thus improved and engine power increased.

In broad principle, the operation of the Chevrolet Ramjet Fuel Injection system is simple. The accelerator controls the volume of air admitted to the engine. A mechanism of the fuel injection system continuously measures the volume of incoming air and automatically meters the precise quantity of fuel to be mixed with the air. Other mechanisms enrich the mixture for acceleration, hill climbing and warm-up, and also insure instantaneous delivery of fuel to the nozzles for starting, smooth engine idling and cut-off fuel when coasting downhill.

The system includes specially designed components, such as an air metering system, fuel metering system and fuel nozzles. The one piece cast iron intake manifold and engine cover used on carburetor model Chevrolet engines is replaced by two separate aluminum castings. The lower casting forms the top cover of the engine, while the upper contains the air passages and mounting for the air metering and fuel metering systems. Other new components include an auxiliary fuel filter, a special ignition distributor which drives a high pressure fuel pump through a flexible drive, and a new electric choking system for cold starting.”

The fuel meter resided on the right side of the engine. Look closely and you’ll see it’s mechanically driven off the tachometer by way of a cable. Fuel from the fuel meter was routed through a “distributor” to eight separate nozzles – one for each cylinder. The air meter is the device bolted to the driver’s side of the intake manifold plenum. The main purpose of the air meter is to measure, control and, along with the plenum, deliver the air required for the combustion process.

Looking Back To The Future

The following YouTube video put out by Chevrolet called “Jet Ace” is a promotional film to highlight the benefits of fuel injection at a time when it was straight out of NASA’s rocket program. Besides the vintage, reminiscent factor, it provides insight into how fuel injection was understood way back then.