When it comes to high-performance applications of any sort, there comes a time when the capabilities of the vehicle’s OEM clutch assembly will have to be evaluated. And when it comes to the clutch assembly, one important component of that assortment is often times overlooked. That component is the flywheel.

If you’ve ever purchased a new clutch assembly, you’ve probably noticed that many aftermarket assemblies do not include a flywheel, and there’s a reason for that. Like many other go-fast parts, the flywheel is not a ‘one-size fits all’ type of component. Every company manufactures its flywheel for different applications, power outputs, and overall drivability.

With so many choices on the market today, it can be difficult to choose the right one for a specific application. We’ve taken the guess-work out by inviting three industry leading clutch and flywheel manufacturers, Quarter Master, SPEC Clutch, and Fidanza Performance for a question-and-answer session to eliminate the guesswork.

Fidanza Performance applies a unique protective coating to identify any remaining oil or residue from its machining process to each of its flywheel and clutch assemblies. The combination is better known as ‘Atomic Green’ for it’s color.

What Is Our Goal?

While the flywheel is not an obscure component to comprehend, selecting the proper flywheel for a specific application is often shrouded in mystery for many enthusiasts. When choosing a flywheel, the right choice ultimately comes down to the intents and purpose of the vehicle, and the amount of power the engine is making.

As we mentioned earlier, the flywheel is a specific component which must also be matched with the correct clutch assembly for that application. Each manufacturer has its own unique process for creating flywheels. An example of this is that some companies use different materials to manufacture flywheel options, or even different lightweight flywheel design styles.

Our goal for this question-and-answer session is to discuss many frequently asked questions regarding the flywheel, and to help enthusiasts gain a better understanding of the science behind them. Whether you’re searching for a flywheel application for drag racing, autocross, road racing, or a daily driver, we’ll help make your choice easier by discussing different materials and manufacturing processes.

Flywheel Materials And Their Affects

Flywheels can be manufactured from any of a variety of materials, including various grades of steel and billet aluminum. With so many different choices readily available, we wanted to know how the different materials can affect the overall integrity of the flywheel and it’s drivability characteristics. This question is important because many enthusiasts have claimed that depending on the material that the flywheel is manufactured out of, it can inadvertently affect the vehicle’s drivability. With so much inconsistency in enthusiast reports of flywheel performance, we felt this was a topic that merits discussion. We reached out to Dan Jenkins of Fidanza Performance, David Norton of SPEC Clutch, and George Hovsepian of Quarter Master.

Flywheels can be manufactured from any of a variety of materials, including various grades of steel and billet aluminum. With so many different choices readily available, we wanted to know how the different materials can affect the overall integrity of the flywheel and it’s drivability characteristics. This question is important because many enthusiasts have claimed that depending on the material that the flywheel is manufactured out of, it can inadvertently affect the vehicle’s drivability. With so much inconsistency in enthusiast reports of flywheel performance, we felt this was a topic that merits discussion. We reached out to Dan Jenkins of Fidanza Performance, David Norton of SPEC Clutch, and George Hovsepian of Quarter Master.

Jenkins/Fidanza: The most common material types include steel, aluminum, and nodular iron. Within these materials, a flywheel can have a specific grade of metal, such as chromoly-steel, 1040-steel, 6061-aluminum, or even 2024-aluminum. These different types of flywheels do not necessarily affect the clutch assembly or operation, as most are actually designed to work with specific style clutches to avoid any adverse affects.

For example, a flywheel manufactured out of 2024-aluminum will work excellent when paired to a button-style race clutch. However, that same flywheel would warp or even flex under the load of a larger style diaphragm clutch. The style of driving or racing will usually determine the need for a specific style clutch, which will strictly translate to the type of flywheel necessary as well.

Norton/SPEC: Steel, aluminum, and titanium are most commonly used to manufacture a flywheel. Steel is the best friction surface for most materials because it offers a good seatability and wear pattern. Aluminum is too soft, and titanium is too hard for most friction materials. SPEC utilizes high carbon-steel and grain-formed forged aluminum to manufacture its flywheel options, which we believe is the ultimate benefit in aluminum-alloy integrity.

The inertia properties of the flywheel can accentuate clutch attributes. For example, a very light flywheel can make a clutch feel more aggressive. The ability of the flywheel to control heat and maintain tolerance can also prolong clutch performance and wear under extreme conditions. The friction surface material and inertia most directly affect how the clutch feels to the end user, and will ultimately dictate other factors, such as performance and wear life.”

Our flywheels are designed as a direct OEM replacement, which means they will meet or exceed all factory tolerances. — Dan Jenkins, Fidanza Performance

On a racecar, the flywheel is often times made as small and light as possible. The lighter and smaller it is and the closer the weight is to the rotational axis, the quicker the engine will be able to reach its maximum RPM. This translates to higher exit speeds coming out of corers and higher top-end speed at the end of the straights on the race track.

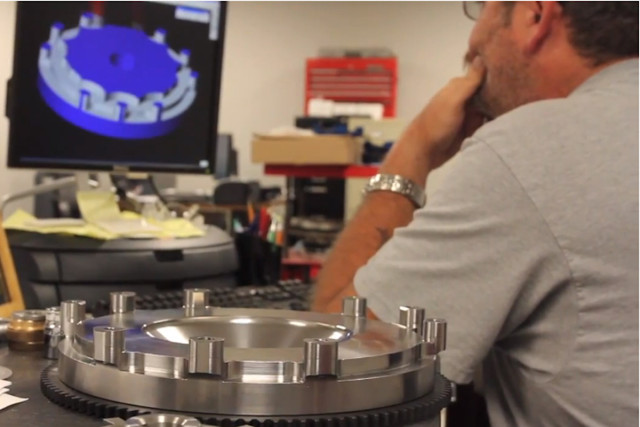

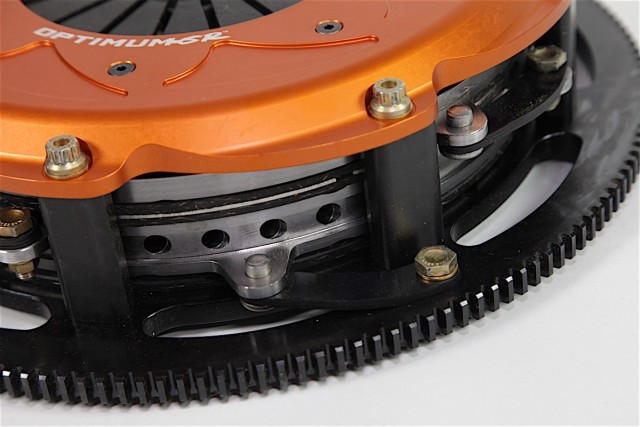

Check out this cutaway of an Optimum-SR clutch from Quarter Master which features a billet aluminum lightweight flywheel.

Flywheel Tolerance — What Is It? Why Is It Important?

The lighter a flywheel is, the faster it spools up RPM; but also means the harder it is to start from a standstill. — George Hovsepian, Quarter Master

Jenkins/Fidanza: Avoiding premature-wear, ensuring correct operation and fitment, and clutch engagement are just some of the reasons a flywheel must be machined to a specific tolerance. The correct tolerances would be matched to what the OEM tolerance is, although this will vary per application. An example of this would be a vehicle’s driveline set-up or the type of clutch being used (pull versus push style).

Quick Tech With SPEC

SPEC reduces unwanted weight on a vehicle’s driveline by reducing mass in its entire clutch assembly, starting with its flywheel. Each flywheel option the company offers is manufactured for a specific vehicle application, and different driving habits.

The company’s billet aluminum flywheel options are manufactured to a specific tolerance in-order to provide the entire clutch assembly with a quiet and functional operating quality, while reducing rotating mass on the driveline components.

Norton/SPEC: The flywheel is the component that contributes the most to the performance and the overall drivability of the clutch system. As it pertains to machining and manufacturing tolerance, parallelism and concentricity are the important measurement standards. The tighter or closer to zero the tolerance, the more balanced the unit will be. This means the flywheel will not require any extra balancing after the machining process. Rotational integrity is maximized, as well as the ability to provide a perfectly flat surface for the clutch disc to optimize wear and performance. Proper step and recess dimensions assure clean and consistent clutch actuation and promote maximum clamp load. SPEC maintains a one-one-thousandth machine tolerance to assure a perfect rotational integrity, fast clutch seating, and maximized drivability.

Hovsepian/Quarter Master: Because the flywheel is a constantly moving mechanical component, and is a sequence of the drivetrain, specific tolerances are required to maintain the balance and alignment with the additional moving parts in the drivetrain.

Discussing Weighted Versus Lightweight Flywheel Options

With so many performance flywheel options on the market today, it can be difficult to understand all of the different items available. Many enthusiasts can agree that a lightweight flywheel is ideal, simply because they have a lower MOI. However, a lightweight flywheel isn’t always ideal depending on the application. This is also why companies manufacture heavier weighted flywheels. To clear up the confusion, let’s discuss the differences between the two.

Jenkins/Fidanza: Although a lightweight aluminum flywheel in certain instances is sufficient, enthusiasts may need a flywheel with more mass, or even one that has less mass than a standard aluminum lightweight flywheel. Most lightweight flywheels can be used in both street cars and race applications. These can be found in drag racing applications, and even for marine use.

Jenkins/Fidanza: Although a lightweight aluminum flywheel in certain instances is sufficient, enthusiasts may need a flywheel with more mass, or even one that has less mass than a standard aluminum lightweight flywheel. Most lightweight flywheels can be used in both street cars and race applications. These can be found in drag racing applications, and even for marine use.

Ultra lightweight flywheels which are designed specific for race applications such as SCCA or SOLO racing and road course tracks these tend to be too light for street use, and can cause adverse affects in regular stop and go driving or traffic like stalling or high revving starts.

Due to the loss in mass, these tend to require changes in your driving habits which can be a bit irritating for daily use. A heavier flywheel, such as billet steel one, will help to carry the momentum of the vehicle in larger vehicles. These types of vehicles require a bit more weight to maintain proper idle and to get the momentum to move off the line. Some drag racers prefer the additional weight to aid in launching off the line. These are a very specific flywheel application and are not meant to be used on the road or in track vehicles, as the additional weight is not necessarily wanted in higher revving applications.

Norton/SPEC: How a specific application responds to driveline inertia depends on vehicle weight, gearing, and engine power curve. Also, enthusiasts must prioritize performance and drivability. Some enthusiasts may want the maximum power gains and choose the lightest unit, whereas others may want the most stock-like drivability and choose a stock weight or slightly lighter flywheel. Many applications have little-to-no drivability downsides when utilizing a light flywheel.

A flywheel imbalance can destroy engine bearings and other driveline components if the flywheel is not balanced, and also not in its allowable tolerance. — David Norton, SPEC Clutch

Hovsepian/Quarter Master: A heavy flywheel (to a certain extent) allows for an easier transition from a standstill to operation. This translates to a safer and smoother drivability on the street. Reducing weight (or MOI) will reduce the time it takes to reach maximum RPM, which is optimal for most road-racing and autocross applications. As with most things, there are going to be trade-offs. The lighter a flywheel is, the faster it spools up RPM; but also means the harder it is to start from a standstill. Great for a road racing application, and not so great on the street or drag strip. In drag racing, having too light of a flywheel will not slow the engine enough to allow for up-shifts.

Check out the full installation of this SPEC Clutch on our autocross C5 Corvette here.

Maintenance: Resurface Or Replace?

At one time or another, most of us have had to replace our clutch assembly in our vehicles; and we all know what a giant pain that can be. With certain factory applications, the OEM flywheel can actually be reused by having it resurfaced, creating a new layer of friction material for the clutch assembly and ultimately avoiding the cost of a replacement. However, in the world of aftermarket flywheel options, this isn’t always the case, as it varies from application to application. So what’s the best option for reliability?

Jenkins/Fidanza: Both styles of flywheel can be found on the market. The two main types are those with a replaceable friction surface allowing for easy replacement and rebuild, and those that are more conventional having a friction area that can be resurfaced within factory specifications. All of our aluminum flywheels include a hardened steel friction surface that is designed to be replaced versus being resurfaced. This route gives you an almost infinite lifespan for the flywheel, allowing it to be rebuilt multiple times without changing the dimensional features required for correct clutch operation. We do offer a lineup of steel flywheels that do not have a replaceable friction surface. These would be resurfaced like a conventional flywheel and do require replacement once the surface gets to its minimum tolerance.

Jenkins/Fidanza: Both styles of flywheel can be found on the market. The two main types are those with a replaceable friction surface allowing for easy replacement and rebuild, and those that are more conventional having a friction area that can be resurfaced within factory specifications. All of our aluminum flywheels include a hardened steel friction surface that is designed to be replaced versus being resurfaced. This route gives you an almost infinite lifespan for the flywheel, allowing it to be rebuilt multiple times without changing the dimensional features required for correct clutch operation. We do offer a lineup of steel flywheels that do not have a replaceable friction surface. These would be resurfaced like a conventional flywheel and do require replacement once the surface gets to its minimum tolerance.

Norton/SPEC: All SPEC flywheel applications can be machined or rebuilt by replacing a removeable friction surface. Many SPEC aluminum flywheel options, as well as certain steel flywheels feature a replaceable friction surface. Additionally, on the manufacturing side, we heat press, fasten — and in certain applications — even weld ring gears to our flywheels. In most cases, a ring gear can be replaced after starter damage or failure, without the end user having to purchase a completely new unit.

Hovsepian/Quarter Master: It is possible to resurface a flywheel in most cases. However, if a flywheel is manufactured for an ultra-lightweight application, then we wouldn’t recommend resurfacing it. When a clutch assembly begins to wear out and needs to be replaced, the friction surface of that flywheel in that clutch assembly is often resurfaced instead of being replaced.

A quick weight comparison between the C5's OEM clutch vs the new SPEC clutch shows a respectable 15-pound weight reduction.

Finding The Perfect Balance

When it comes to flywheel options, more specifically, a lightweight flywheel, many enthusiasts worry about the ‘issues’ associated with them. We’ve all heard stories of clutch chatter, balancing issues, and possible damage caused to the driveline components. Balancing a clutch assembly is crucial to its ability to properly function, and it all starts with a balanced flywheel. The question is, do enthusiasts have to balance the parts themselves?

Jenkins/Fidanza: It is highly recommended to balance the flywheel and clutch assembly together before installing them into the vehicle. Most flywheels we produce are designed as a neutral, or as close-to-zero balance as possible, and are independently balanced to ensure they meet the criteria set for proper balance weight and are within the allowable tolerances. Issues can still come up if the two pieces are not balanced together, creating small problems like vibrations or chatter, or even larger issues like crank bearing wear, seal wear, or worse. Depending on the severity of the imbalance, it could lead to serious damage to the entire driveline if the issue is not addressed.

Jenkins/Fidanza: It is highly recommended to balance the flywheel and clutch assembly together before installing them into the vehicle. Most flywheels we produce are designed as a neutral, or as close-to-zero balance as possible, and are independently balanced to ensure they meet the criteria set for proper balance weight and are within the allowable tolerances. Issues can still come up if the two pieces are not balanced together, creating small problems like vibrations or chatter, or even larger issues like crank bearing wear, seal wear, or worse. Depending on the severity of the imbalance, it could lead to serious damage to the entire driveline if the issue is not addressed.

Norton/SPEC: SPEC flywheels are precision-balanced before shipment, as well as balance-checked after being paired with a clutch assembly, which is also balanced after production. Balancing a flywheel is very important for rotational integrity and safety, and drivability. A flywheel imbalance can destroy engine bearings and other driveline components if the flywheel is not balanced, and also not in its allowable tolerance.

Hovsepian/Quarter Master: Whether it’s a lightweight or neutral weighted flywheel, it must be balanced — no question about it. If the flywheel and clutch assembly are out of balance, noise, vibration, and harshness levels will dramatically increase, and will inevitably cause extreme damage to the engine, transmission, or driveline. It’s recommended to balance the entire assembly as a whole after verifying the tolerance level of the flywheel itself. This is, of course, after the flywheel has been balanced as well.

Hovsepian/Quarter Master: Whether it’s a lightweight or neutral weighted flywheel, it must be balanced — no question about it. If the flywheel and clutch assembly are out of balance, noise, vibration, and harshness levels will dramatically increase, and will inevitably cause extreme damage to the engine, transmission, or driveline. It’s recommended to balance the entire assembly as a whole after verifying the tolerance level of the flywheel itself. This is, of course, after the flywheel has been balanced as well.

Wrapping Things Up

The manufacturers we involved in this article have dedicated an immense amount of research and engineering to develop a high-performance, highly capable flywheel for virtually any application imaginable. With that in mind we asked each for some strong tips, tricks, and general words of wisdom and information for enthusiasts regarding flywheel selection.

Jenkins/Fidanza: One of the biggest issues that an enthusiast may overlook is ensuring the friction area is clean of debris and greases or oils before installing the flywheel. Cleaning this surface prior to the installation is paramount for proper clutch engagement and lifespan.

Norton/Spec: Chassis setup, power curve, gearing, and tires are variables to consider when choosing inertia properties. The goal is to make a power application the most efficient, as it’s not always about where the car is driven.

Hovsepian/Quarter Master: If an enthusiast plans to re-use the existing flywheel for a new clutch assembly, we’d recommend the flywheel be machined to a new tolerance. This eliminates any imperfections on the surface and ensures a proper seating position in the clutch assembly, ultimately protecting the assembly and creating a safeguard.