There is nothing more critical to the way your engine runs than the camshaft and companies like Competition Cams are constantly on the lookout for ways to increase a cam’s potential. It’s been called the brains of the engine for good reason. While a component list that is designed to work together will provide optimum power and durability, the camshaft is the one component that will open the door to enjoy all that potential. Think about it, what is the ratio of cam swaps compared to any other component within an engine? The effect that a cam’s specs has on an engine’s power output is why they are most often swapped when searching for power, and why they are the darling of cam-comparo stories.

Flat tappet cams have received a bit of a black eye recently, but even roller lifter camshafts can succumb to improper installation or break-in.

They also have had their share of getting a bad rap. Seasoned enthusiasts will recall in the not-too-distant past when breaking in a flat-tappet cam was almost considered as precarious as standing on thin ice with heated sneakers. There were several things that contributed to the ill-fated camshafts, many of which, were not the fault of the camshaft at all. Truth be told, camshaft failures are not relegated to flat-tappet cams alone.

We asked Comp’s Billy Godbold about today’s production ratio of flat-tappet to roller camshafts. He mentioned that Comp has two CNC’s typically on flat-tappet cams where seven are on roller cams. He estimates approximately 25-30% of camshaft production to still be flat-tappet types. Even so, taking steps to ensure your cam lives a long life are still just as important.

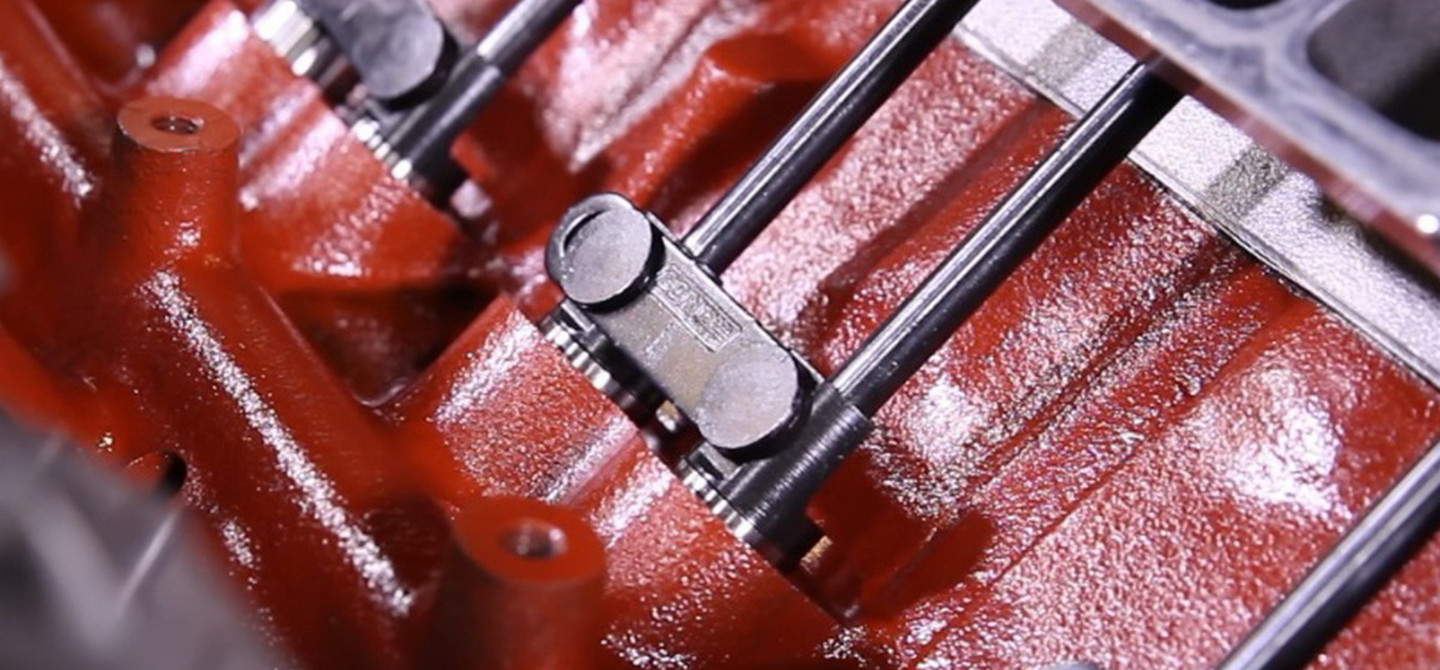

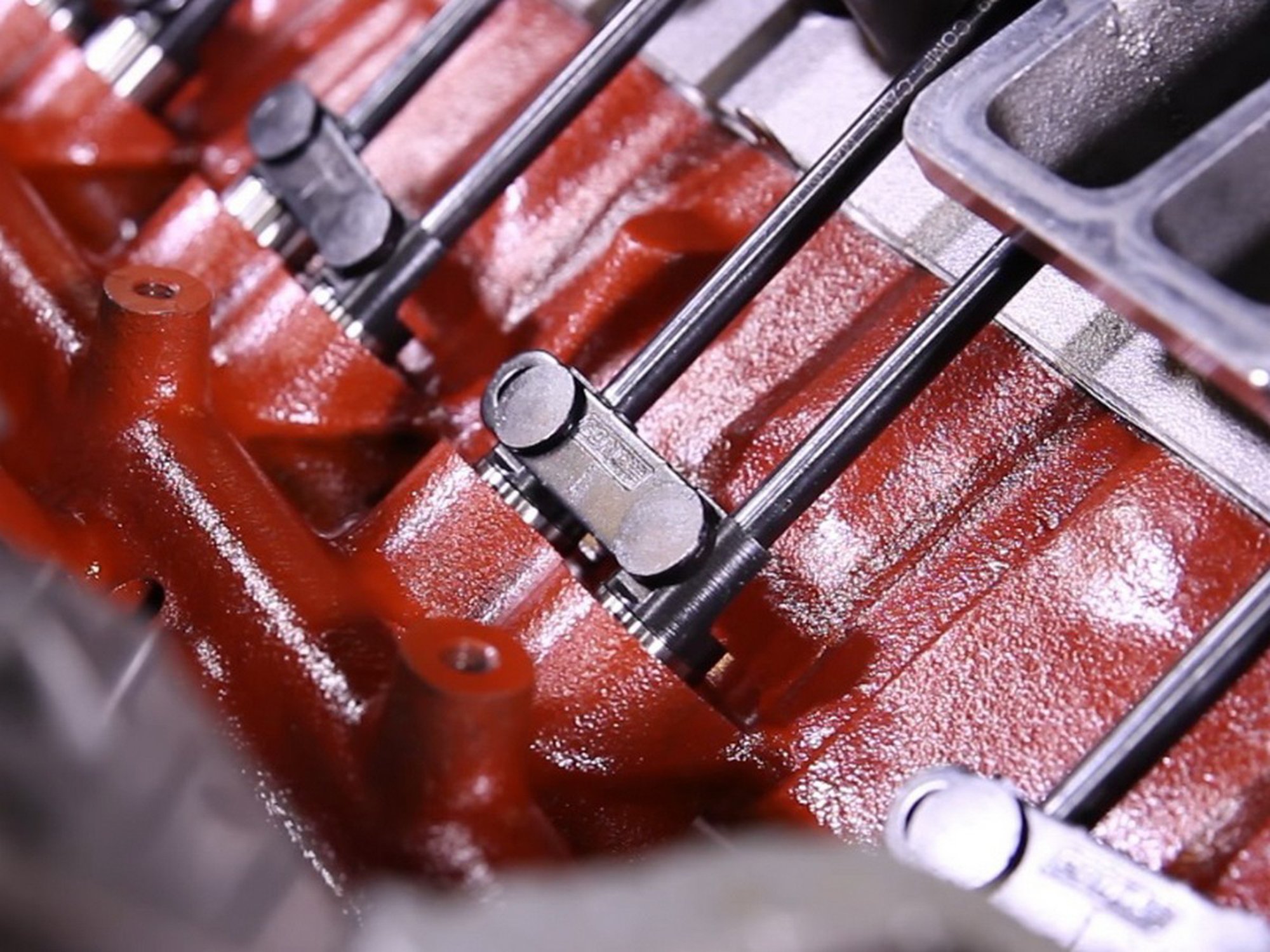

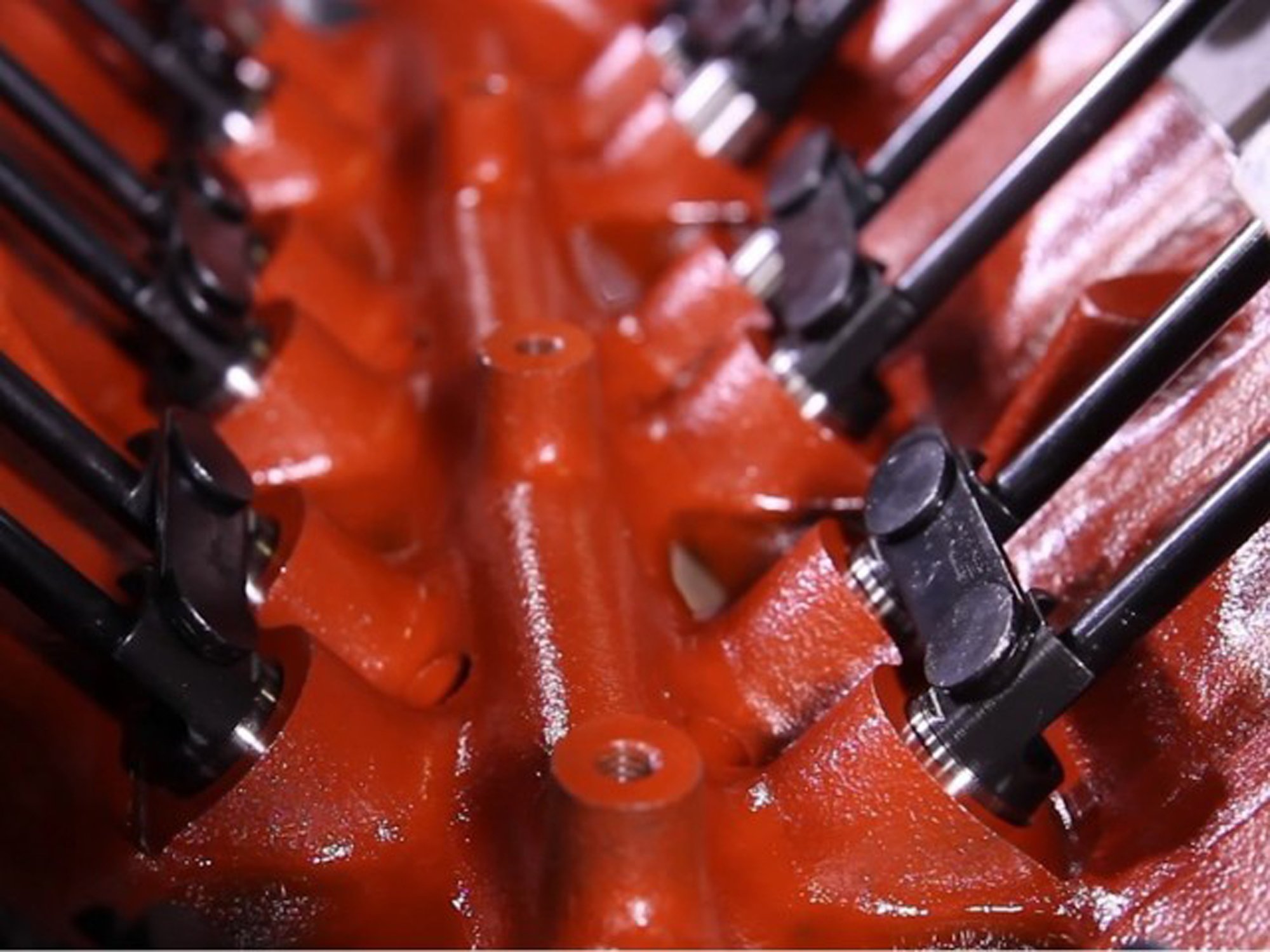

What goes on topside is just as important as choosing the right cam specs for your application. Mismatched parts and binding are often contributors to cam failure.

In this Wednesday Rewind, we take a look at the Top 10 reasons why cams and lifters fail in an engine. The story 10 Reasons For Camshaft And Valvetrain Failure From COMP Cams focuses around a video produced by Comp Cams that goes through the most common reasons for failed cams and lifters. While flat-tappets do get their moment under the hot lights, many of the reasons why cams fail would eat up a camshaft no matter what lifter it had.

Between the improved education, improved surface finish and improved lubrication & cleanliness, the customers are having far better results! – Billy Godbold, Comp Cams

There are also new, added benefits that contribute to longer living camshafts. Billy explains, “We have been changing our grinding process to approximately double the effective bearing area on the roller cam lobe surfaces. By improving the finish and surface contour, we have allowed the wheel to spread the load out over more of the surface, greatly reducing the maximum microscopic contact stress “hot spots”.

Do YOUR Part

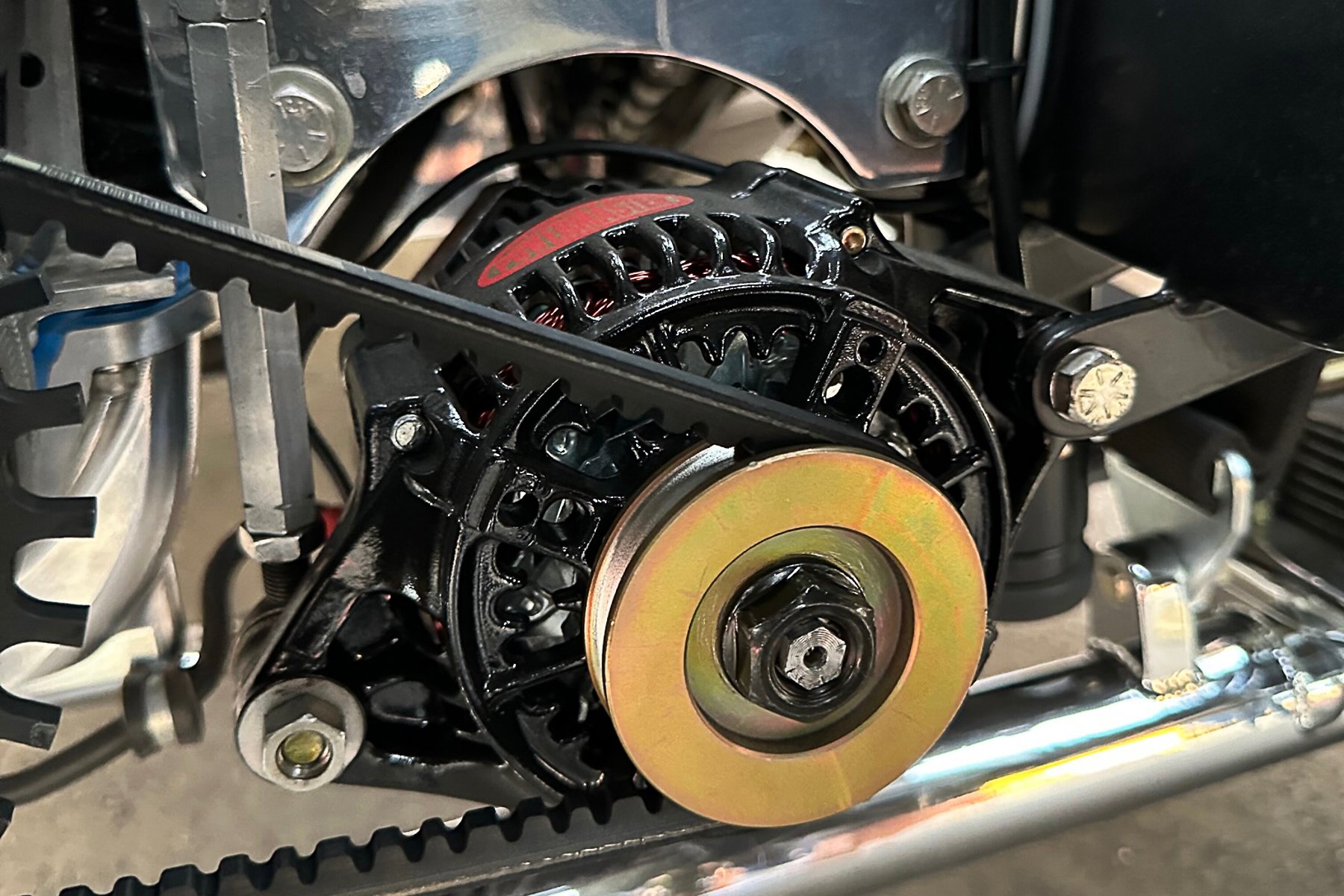

Do you understand the extent that your engine’s ignition could dictate cam durability? Also, bring up cam break-in at any car show or cruise-in, and you’ll hear all about additives and engine revolutions per minute. But did you know that how the engine is assembled can have more say in the life-span of your cam than anything you could pour in a valve cover? Sure, proper break-in procedure is important, but if parts are binding, your engine is doomed way before the coil ever sees a charge.

We echo Billy’s thought that it is a multi-faceted responsibility to keeping cams alive, “Between the improved education, improved surface finish and improved lubrication & cleanliness, the customers are having far better results! ”

Clearances and proper components deep within your engine also contribute to camshaft life. Roller rockers aren't impervious to dirt and contamination and your pushrod choice can also bring clearance and durability issues.

Cam break-in is important. That’s why it is one of the 10 items addressed in the video. But there are nine others that also contribute to the life span of one of the most influential components in your engine. That’s why it bears repeating, and that’s why THIS STORY is this week’s Wednesday Rewind.