When Holley introduced the Street Demon a few years back, it changed the carburetor scene. With several features not seen before, the new carburetor was a hot commodity for the mild street-performance vehicle. Nothing has changed in the years since its release, and the carburetor is still popular among car enthusiasts.

However, the Street Demon is not your typical four-barrel Holley. If that’s what you are used to, then the Demon might look a bit scary. We asked Bill Tichenor of Holley Performance, why someone would choose a Street Demon over, let’s say a Holley 4160 carburetor? “The Street Demon is a two-piece design with all gaskets above the fuel level. The primary bores are small in comparison to a standard 4160 Holley, and it has Triple Stack boosters. The combination of these things means the Street Demon has great throttle response, and the small primaries also means fuel economy is maximized.” Bill continued, “The polymer fuel bowl option is a great feature of the Street Demon, as it reduces fuel temps by 20 degrees, which can be important with today’s various fuel blends.”

With that said, this article will shed some light on how the Street Demon works, as opposed to the traditional-style Holley carburetor. It will also cover adjustments available on the Street Demon and their effects.

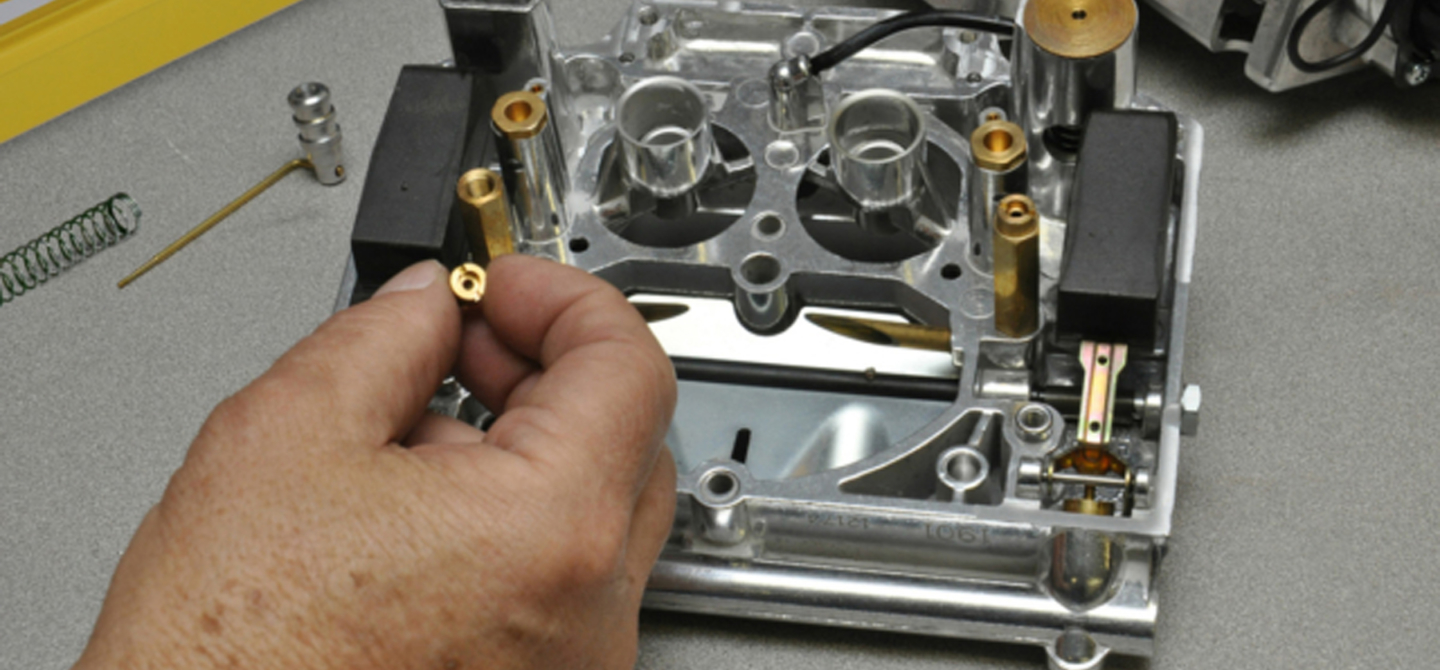

It is immediately apparent that the Street Demon is designed a bit differently than a traditional Holley. The fuel bowls and main body are one piece on the Street Demon (left), while the traditional Holley has removable metering blocks (center) and side-mounted fuel bowls (right).

Steady-State Cruising

A typical Holley carburetor has two screw-in jets that meter the amount of fuel that flows to each primary venturi. These jets are simply a fixed orifice, and a numerically larger or smaller jet will increase or decrease the orifice size respectively.

Demon’s Triple Stack Boosters help atomize the fuel feeding from the primary venturii. Although it appears to only be two stacks, the third is part of the carburetor body.

A larger orifice will allow more fuel to pass through, resulting in a richer air-fuel mixture. A smaller orifice will restrict fuel, and result in a leaner mixture.

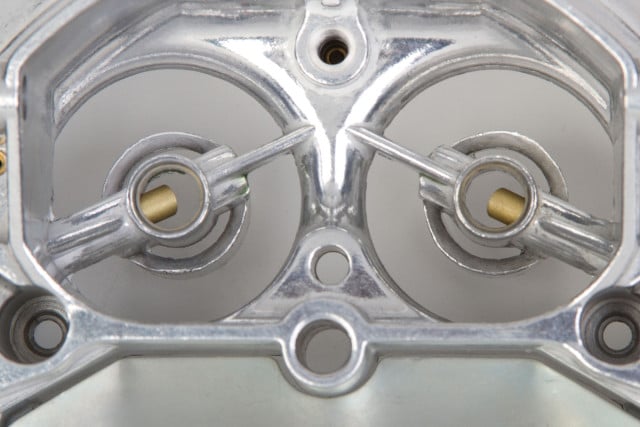

The Street Demon also uses jets for its primary metering, however, a metering rod is used to control fuel flow in conjunction with the jet. This rod fits through the center of the main jet, and the diameter of the metering rod and the jet size both play a role in fuel delivery.

With the Street Demon, the larger the metering rod diameter, the more area of the jet orifice that is taken up, resulting in a leaner mixture. Remember, the metering rod fits inside of the jet. A larger diameter means less area around the rod for fuel to flow. A smaller diameter rod takes up less space inside the jet, meaning more area for fuel flow.

Part-Throttle Acceleration And Power Enrichment

Since jets are a fixed orifice, that means the volume of fuel that can flow through it is also fixed. However, the engine requires more fuel during times of heavy load, such as during acceleration or pulling a trailer up an incline, than when cruising at steady highway speeds. Therefore, there has to be another source in which to draw fuel, other than the main jets. This is accomplished through the circuit known as power enrichment.

The metering rod and primary jet work together to meter fuel during steady cruising and part-throttle acceleration.

Traditional Holley carburetors use a power valve. These are vacuum-activated valves located in the metering block of the traditional style carburetor. As load increases on the engine, engine vacuum is reduced, and fuel requirements increase. The power valve opens at a specific vacuum level, allowing additional fuel to enter the venturi.

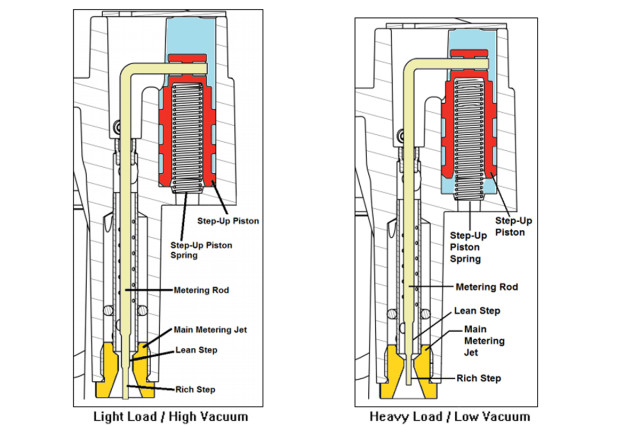

The Street Demon’s power enrichment operates on the same principle, but without a power valve. The metering rod discussed earlier has two different diameters, or steps, that pass through the primary jet. Each metering rod is connected to a step-up piston controlled by engine vacuum, and a spring assembly.

When engine vacuum is high (during highway cruising for example), the vacuum overcomes spring pressure, and holds the larger diameter step on the metering rod in the center of the main jet. This reduces the area available for fuel to flow. However, when vacuum decreases due to increased load, spring pressure moves the metering rod up, locating the smaller diameter step in the center of the main jet, effectively allowing additional fuel into the engine.

Transitions Via The Accelerator Pump

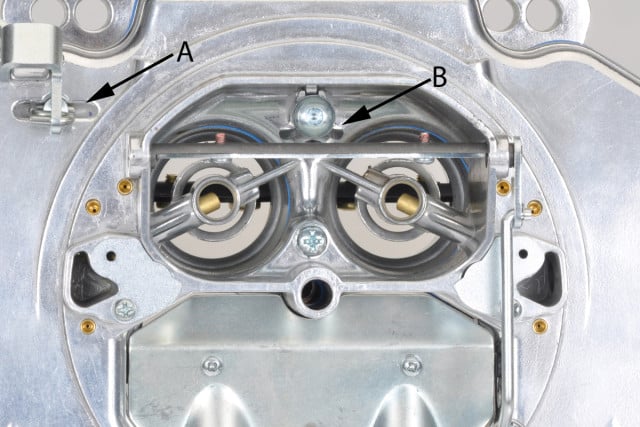

The accelerator pump (A) sends additional fuel through a dedicated circuit to the discharge nozzle (B).

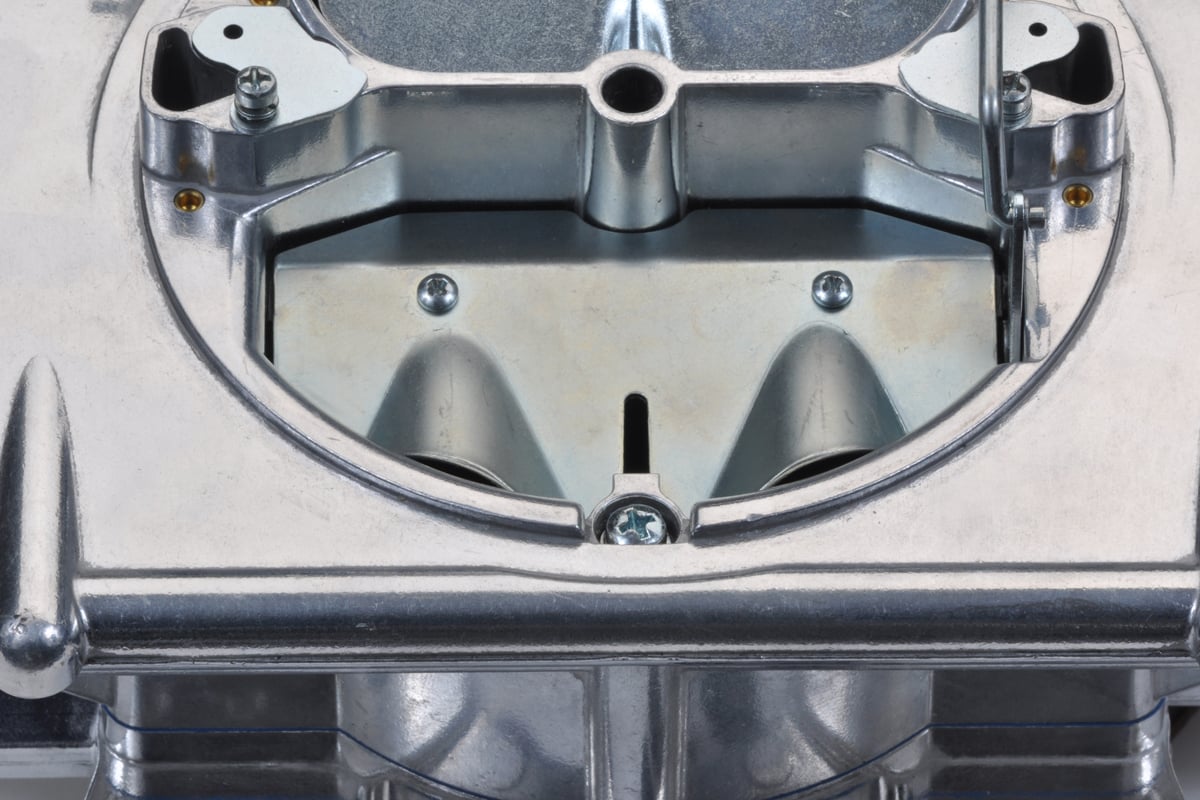

Anytime the throttle is opened, there is a transition time required for the carburetor circuits to operate. A hesitation or lag may result during this transition and influx of air. For this purpose, the carburetor has an accelerator pump. The accelerator pump provides a single shot of fuel directly into the venturi, through a dedicated circuit and discharge nozzle, or “squirter,” each time the accelerator is pressed.

Once the pump shot is depleted, the accelerator must be lifted to refill the pump. This is why pumping the pedal on a carbureted vehicle aids in starting the engine. Every time the accelerator is pumped, fuel is shot directly into the engine.

Accelerator pump operation is virtually the same on the Street Demon when compared to the traditional Holley. However, location of the pump is not. The pump is built into the top plate of the Street Demon, as opposed to the bottom side of the fuel bowls like on the traditional Holley.

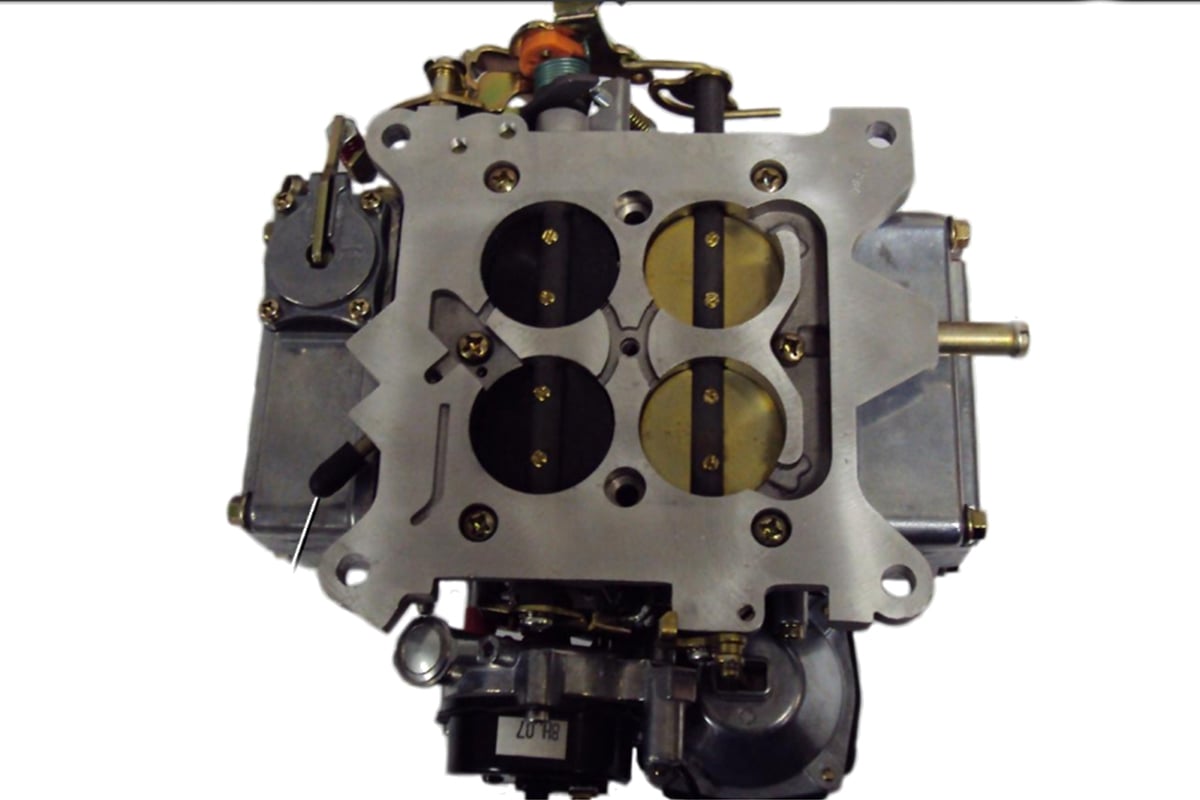

There are two types of secondaries available on the traditional style Holley: vacuum or mechanical. Street carburetors perform well with vacuum secondaries, as the secondaries only open when there is demand for additional air. Mechanically-controlled secondaries require an additional accelerator pump to avoid a lean hesitation when the secondaries are quickly opened. Hence the popular “double-pumper” name. These are found mostly on race vehicles.

Goggles Required

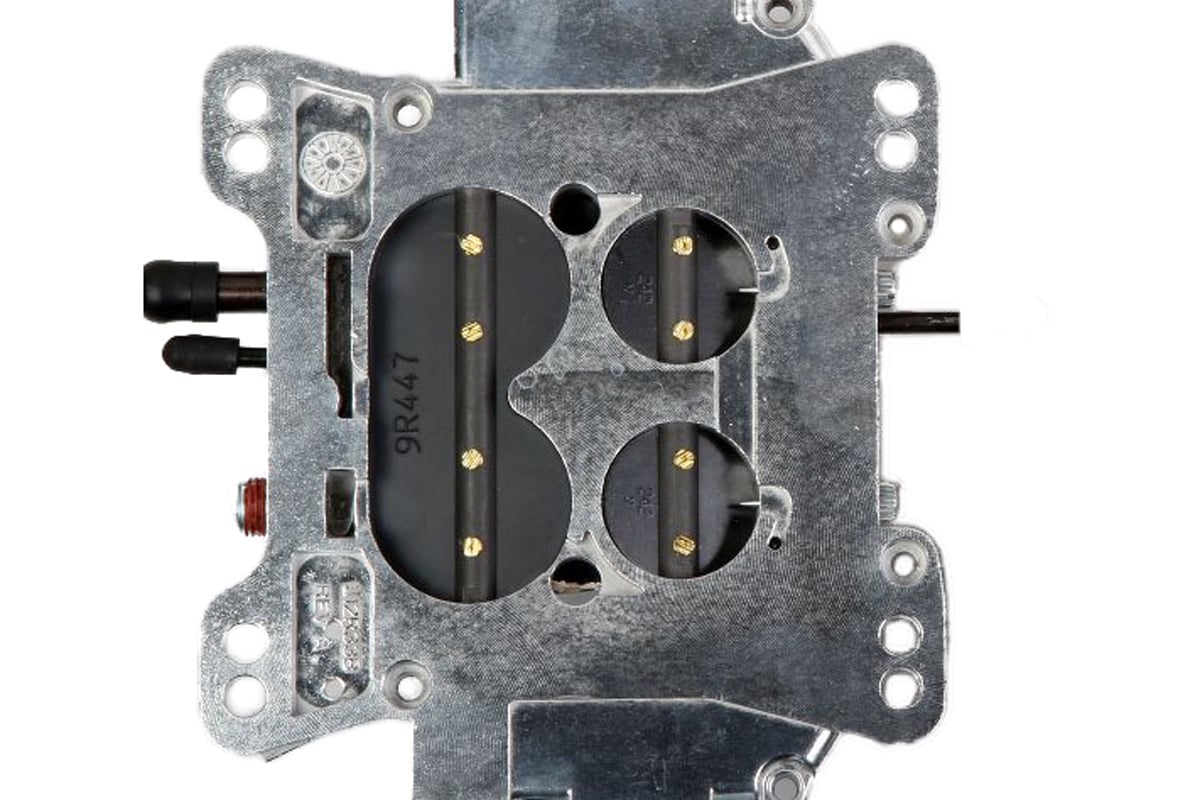

The Street Demon replaced the traditional style secondaries with one, curiously shaped valve. The patented Goggle Valve Secondary (GVS) provides over twice the air flow of the primaries. This allows the Demon carburetor to utilize smaller primaries, which aid in crisp throttle response while still providing an adequate cfm rating. Naming the GVS was easy, considering the eye goggle shape, which is the result of Siamese secondaries with a notch for dual-plane intakes.

The Street Demon has a sort of hybrid version of the two. The actual secondary throttle-plate is mechanically actuated, but progressive linkage begins to open the secondaries when the primaries are opened approximately 30 degrees. At this time, the secondaries then open progressively faster until reaching full-throttle at the same time as the primaries. However, instead of an additional accelerator pump, the Demon carburetor uses a spring-loaded air valve to control the transition.

The secondary air valve is nothing more than an aluminum flap that closely resembles a choke plate, which restricts airflow into the secondary venturi. As the secondary plate opens and air requirements increase, pressure drops in the venturi, causing atmospheric pressure to push the flap open. Spring pressure controls the amount of pressure differential that is required to open the valve. The result is a smooth secondary transition, regardless of how fast the throttle is opened.

(Left) A traditional style four-barrel throttle plate. (Center) The Secondary Air Valve controls air flow into the Siamese secondary, dubbed the Goggle Valve (Right), on the Street Demon.

Adjustments And Their Effects

Now, with a solid foundation on how the Street Demon operates, it is much easier to determine what type of adjustments should be made, if any. Adjustments to the carburetor should only be performed if the engine, ignition, and the rest of the fuel system are in good working condition. Several drivability concerns can be corrected by small adjustments to the carburetor, but even the most drastic adjustment will not cure an issue with another system or component.

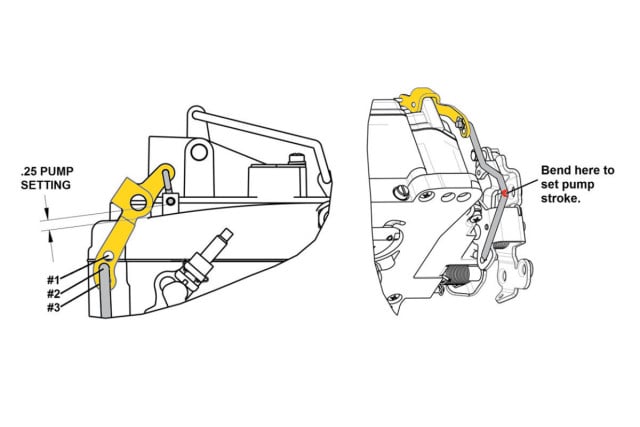

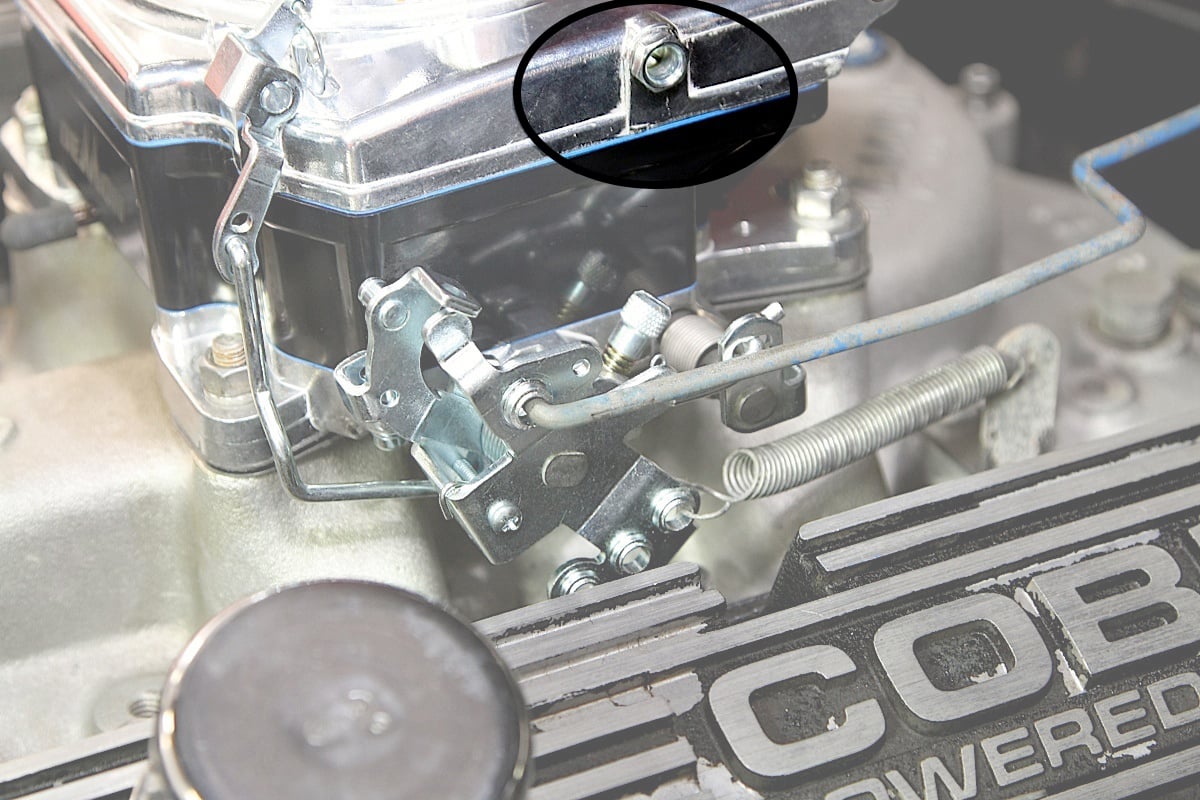

Accelerator Pump-Rate And Stroke

Some vehicles may require more or less of a pump shot when opening the throttle. Demon made this adjustment quite simple, by supplying three separate holes on the linkage. The accelerator pump connecting rod comes from the factory, installed in the center hole. If the vehicle experiences a stumble on initial acceleration, then it may be necessary to change the rate of the pump.

By moving the connecting rod to the top hole, the discharge rate of the pump increases, delivering the pump charge to the engine more quickly. If this makes the stumble worse, it may be getting fuel too quickly. Try moving the rod to the bottom hole in this case. This will slow the discharge rate down, allowing the throttle plates to open further before the pump is empty.

It is important to note that when the discharge rate is changed by moving the connecting rod, the pump stroke needs to be reset. When the throttle is closed, play in the connecting rod should be eliminated, and the distance between the actuating-lever connection and the body should be set to the correct specification. The pump stroke is adjusted by carefully bending the connecting rod.

We have ran 500 horsepower LS engines on our dyno with the 625 cfm Street Demon. – Bill Tichenor

Jet And Metering Rod Adjustments

As previously discussed, the metering rods and primary jets work together to meter fuel. If you find the carburetor is too rich or too lean, a metering rod change is in order. The metering rods are a dual step design: a lean step for steady state cruising, and a rich step for power enrichment under heavy loads. Selecting a smaller diameter metering rod will richen the air-fuel mixture, while a larger diameter rod will lean the mixture out.

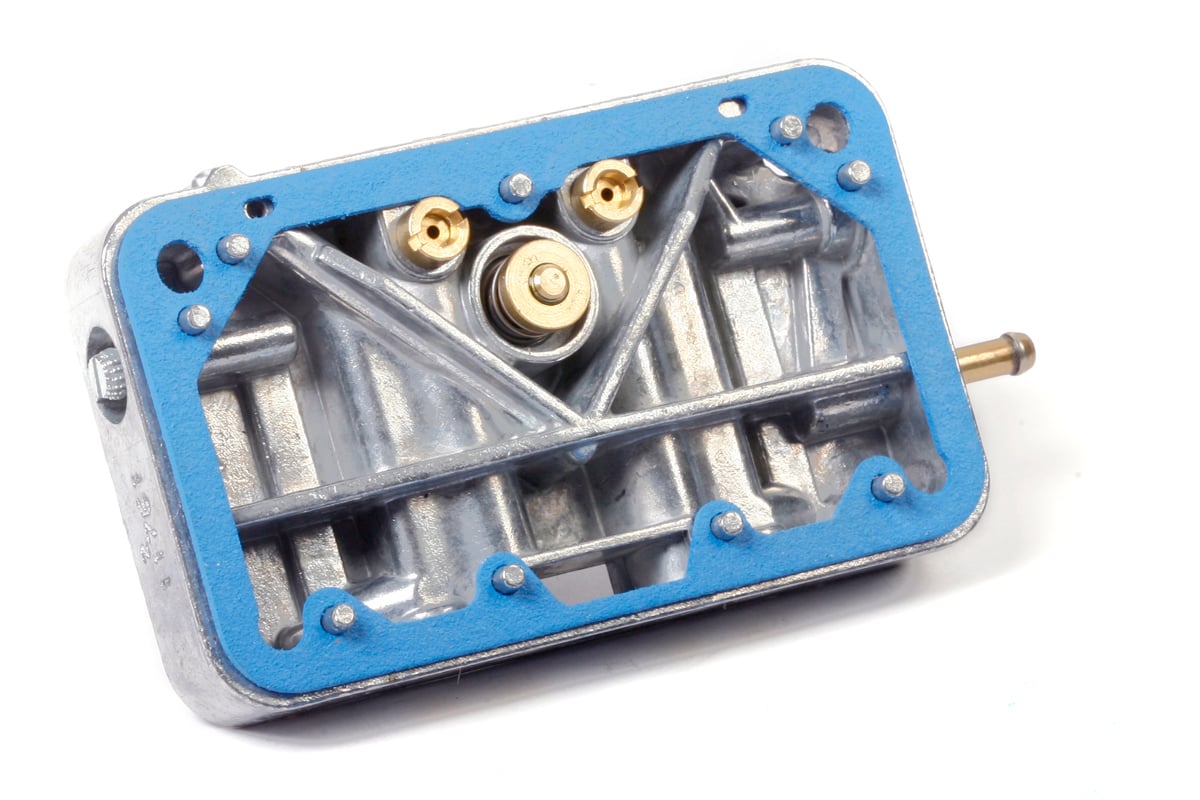

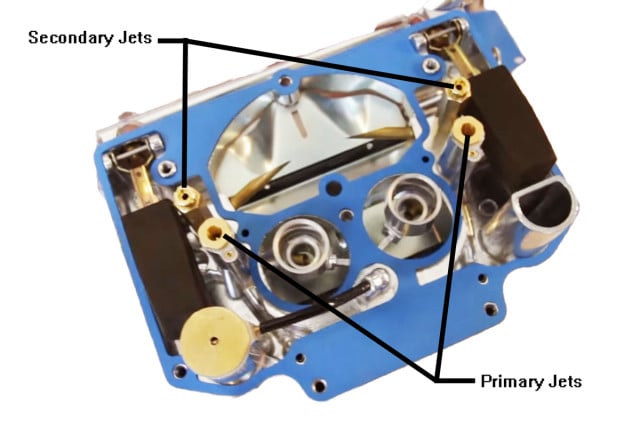

(Left) Metering rods are a dual-step design. (Center) Primary jets are specially designed to accept the metering rod steps. (Right) Secondary jets are the same on the Demon as a traditional Holley.

It is recommended to make changes in the metering rod by .02-inch increments to keep tabs on the effects. If the desired result is not achieved by changing metering rods, the jet needs to be changed. Primary jets are specifically designed to accommodate the metering rods, and cannot be interchanged with the secondary jets. Jet sizes should be increased or decreased by two sizes at a time.

Remember, primary jets and metering rods will affect steady cruising and part-throttle operation. Wide-open-throttle mixture should be adjusted by changing the secondary jets, but only after all other circuits are properly tuned. Secondary jets are the same as used in traditional style Holley carburetors.

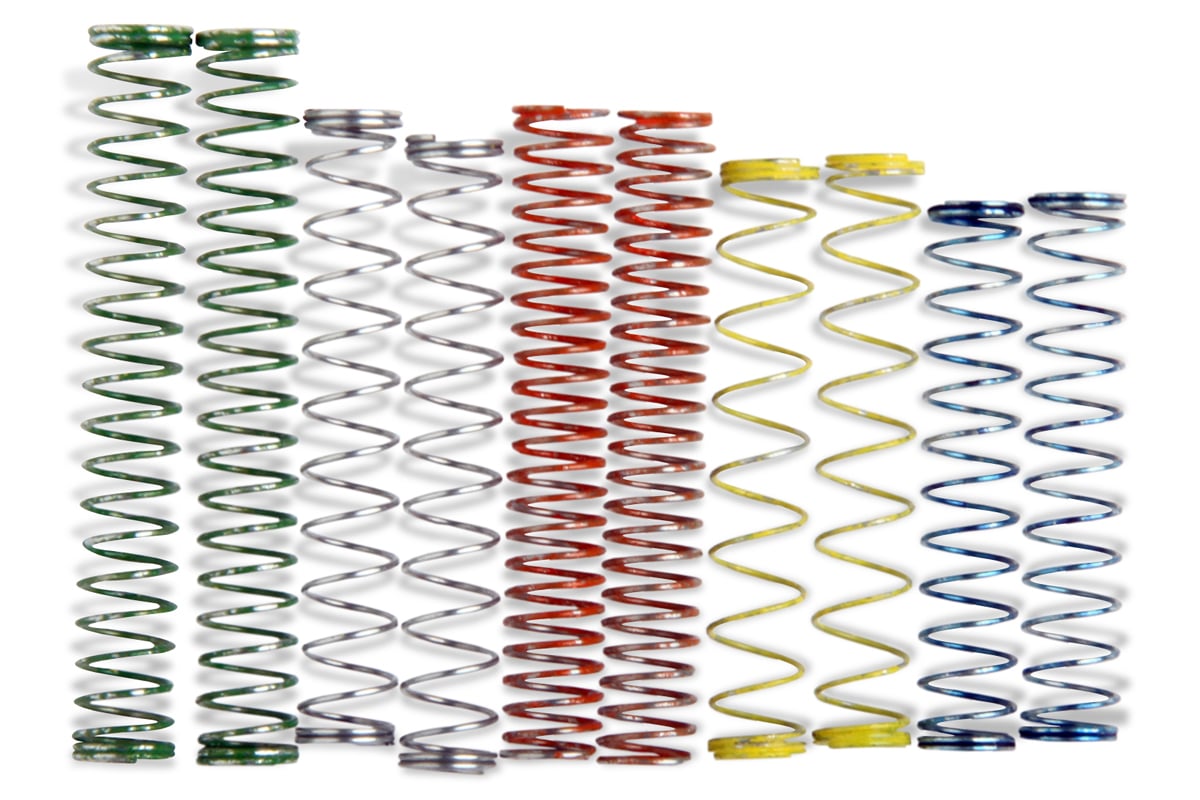

Step-Up Springs

If the vehicle is experiencing a hesitation at part-throttle that disappears when introducing more throttle, there is a good chance the step-up spring is too light. Engine vacuum at part-throttle may be too much for the light spring, causing the piston to stay down, centering the lean step on the metering rod in the jet. A stronger spring will cause the piston to rise at a higher vacuum level, allowing the rich step to flow more fuel. On the other hand, if you are running rich at idle, make sure the spring isn’t too heavy, as this may cause the piston to be stuck in the up position.

(Left) Step-Up springs come in a variety of rates. One screw access makes swapping springs a breeze.

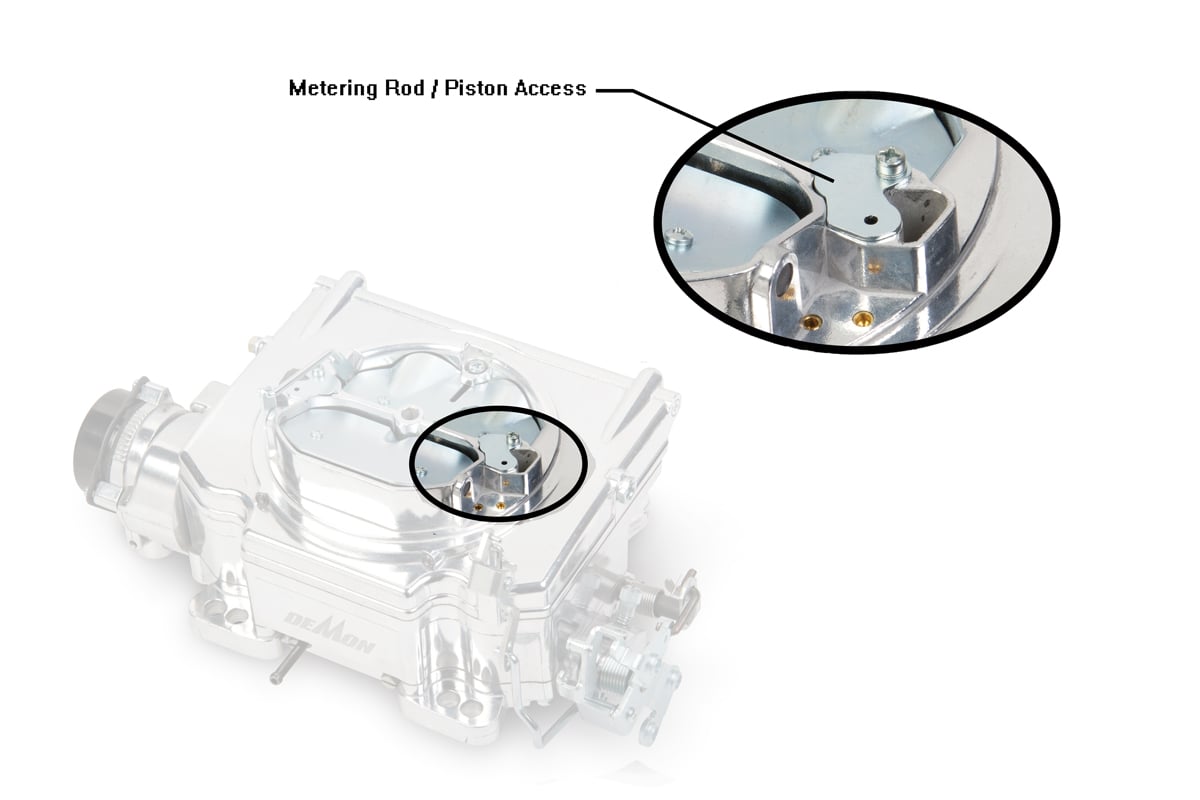

Accessing Metering Rods And Step-Up Springs

To access the metering rods and step-up springs, simply loosen the Phillips head screws from the access covers on the top of the carburetor. Next, pivot the covers to the side and pull the piston, spring, and metering rod out. Make any changes, and then slide the components back into place and tighten the screw.

Jets, on the other hand, require some disassembly to access. There are eight screws total, two accessed from the top and six from the bottom, that need to be removed. Linkage from the choke rod and accelerator pump must also be removed. Follow the detailed guide available on Holley’s website if any questions arise.

Adjusting The Secondary Air Valve

The last adjustment to cover is the secondary air valve. Timing the opening of the valve is critical for a smooth increase in power when the secondary throttle plate is opening. If you feel the secondary opening, chances are the air valve is opening too soon. What you are feeling is actually a lean hesitation. To remedy this, simply hold the air valve torsion spring with a flat blade screwdriver, while loosening the lock nut.

Turn the spring counter-clockwise to increase spring tension and tighten the locking nut. This will delay the opening of the valve, allowing a stronger signal at the secondary venturi to draw more fuel into the engine. It is recommended to make quarter-turn adjustments at a time to the torsion spring. Also, be sure to hold the spring with the screw driver whenever the locking nut is loose, otherwise the spring will unwind, causing you to lose the adjustment.

(Left) Secondary Air Valve adjustments are made by turning the torsion spring on the side of the carburetor. (Right) A calibration kit is available from Holley that provides for a variety of adjustments.

Finally, we asked Tichenor if their are any horsepower limitations on the Street Demon, and he told us, “The Goggle Valve secondaries provide a big gulp of air when maximum horsepower is desired. We have ran 500 horsepower LS engines on our dyno with the 625 cfm Street Demon.”

So there you have it, the street Demon is a true all-purpose street-use carburetor, and now that you know how to tune one, what are you waiting for?