New-generation Corvettes and small-block engines don’t come around every day, so the General Motor’s recent announcement, which we covered here, was particularly important. At the company’s state-of-the-art Powertrain facility in Pontiac, Michigan, the wraps were taken off the Gen 5 small-block for the upcoming seventh-generation Corvette. It will go on sale later in 2013 as a 2014 model.

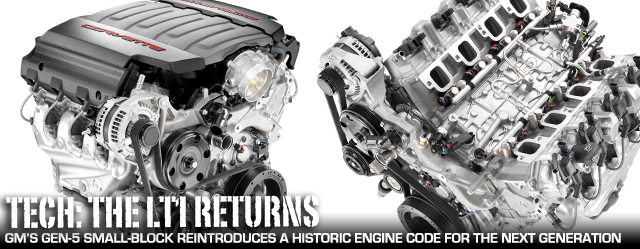

The fifth generation small-block reintroduces the LT1 moniker – last used on the 1996 Corvette and ’97 Camaro Z28 – with a host of advanced technologies that Chevrolet says will make it the most fuel-efficient Corvette ever. Preliminary estimates tag the new LT1 with 450 horsepower and 450 lb.-ft. of torque with the same 6.2-liter displacement as the current LS3 engine.

The new LT1 6.2L Gen 5 small-block for the 2014 Corvette is estimated at 450 horsepower and 450 lb.-ft. of torque. GM says it represents the most significant revamp of the small-block in its history.

That’s about 5 % more power than the LS3, but consider this: The new LT1 will deliver about 230 % more horsepower than the 1955 Corvette’s original, 265-cid, 195-hp small-block from only 42-% greater displacement. “The new Corvette’s LT1 represents the most significant redesign in the small-block’s nearly 60-year history,” says Sam Winegarden, vice president, global powertrain engineering. “More than just great horsepower, the LT1 has been optimized to produce a broader power band. Below 4,000 rpm, the torque of the Corvette LT1 is comparable to that of the LS7 out of the current Corvette Z06. The LT1 is a sweetheart of a power plant and drivers will feel its tremendous torque and power at every notch on the tachometer.”

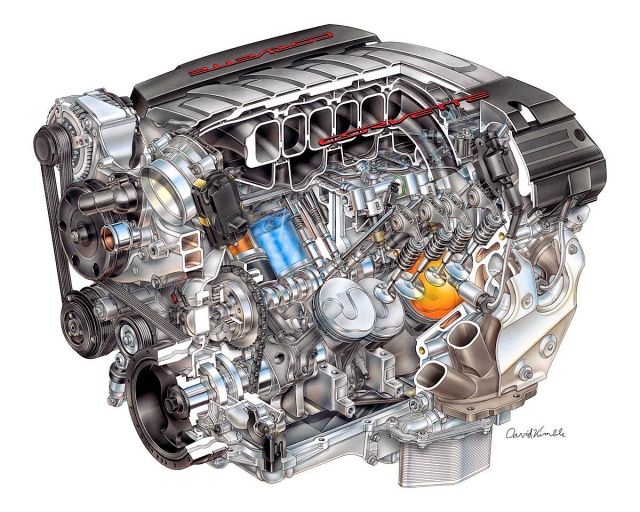

The greater power and efficiency are due mostly to technologies never before employed together on the Corvette, including direct-injection, Active Fuel Management and continuously variable valve timing. An all-new combustion system was developed to optimize the technologies, although it is the primary enabler of the direct-injection fuel system.

As its name implies, direct-injection introduces fuel directly into the combustion chamber, rather than into the intake manifold with a conventional port-injection system. It enables greater combustion efficiency with a more complete burn of the fuel in the air-fuel mixture. This is achieved by precisely controlling the mixture motion and fuel injection spray pattern. direct-injection also keeps the combustion chamber cooler, which allows for a higher compression ratio – 11.5:1 in the LT1 – for more power.

In a nutshell, the new LT1 makes more power with less fuel. Talk about a win-win.

Although similar to previous LS block designs, the LT1 block is a new casting and incorporates oil squirters.

New Combustion System

Although GM has several years worth of direct-injection experience under its belt, it has all been with dual-overhead-camshaft engines. Designers had to start from scratch for the LT1, as the overhead valve/two-valves-per-cylinder arrangement was completely different than the DOHC designs. In fact, the flow field – the motion of the air/fuel mixture – is more complex with an overhead-valve design and direct-injection requires more mixture swirling for optimal combustion.

An all-new cylinder head design supports the engine’s direct-injection fuel system. The valve positions are reversed, compared to Gen 3 and Gen 4 LS engines. They measure 2.13 inches on the intake side and 1.59 inches for the exhaust.

Designers considered about 75 versions of combustion systems for the Gen 5, before a final design was selected. The resulting cylinder head design for the Gen 5 is all-new, along with a new, “sculpted” piston design. The pistons feature risers at the top to direct the fuel spray for a more complete combustion, while the spark plug angle and depth have been revised to protrude farther into the chamber, placing the electrode closer to the center of the combustion to support the direct-injection system.

Another significant change with the LT1 is the reversal of the position of the intake and exhaust valves, compared to the Gen 4 small-block.

The change enables a straighter path for the air charge into the combustion chamber. The airflow enters the combustion chambers via large, 2.13-inch hollow intake valves and exits through 1.59-inch hollow sodium exhaust valves. The valves are held at new, 12.5-degree intake/12-degree exhaust angles, vs. the Gen 4’s 15-degree angle, and splayed slightly to reduce shrouding and enable greater airflow.

In place of the conventional flat-top piston, the new LT1 features an intricately sculpted head designed to help direct the fuel spray of the direct-injection system.

There’s a lot going on with the LT1’s camshaft: At the front is the phaser mechanism for variable valve timing and at the rear is an additional triangular lobe that drives the engine-mounted high-pressure fuel pump for the direct-injection system. Also, A close-up look at the combustion chamber reveals how far the spark plug protrudes into it, to get the flame closer to the center of the chamber.

Along with direct-injection, the Corvette employs Active Fuel Management for the first time, which is GM’s term for cylinder deactivation technology, which shuts down half of the cylinders in light-load driving to safe fuel. Yes, that technically means a C7 may cruise down the freeway as a four-cylinder but the inherent torque of the big-displacement 6.2-liter engine and seamless switching between V-4 and V-8 modes makes the phenomenon essentially imperceptible.

An overview shot without the intake manifold reveals the complexity of the direct-injection fuel system. Also note the “towers” between the coil packs. They’re part of the LT1’s unique PCV system.

Similar But Different

Compared to the Gen 4 engine, the Gen 5’s cylinder block casting is all-new, but based on the same basic architecture. It was refined and modified to accommodate the mounting of an engine-driven direct-injection high-pressure fuel pump. It also incorporates new engine mount attachments, new knock sensor locations, improved sealing and provisions for oil-spray piston cooling.

The engine-driven fuel pump – driven by an extra lobe on the camshaft – is a game-changer for the Gen 5 small-block. It’s also mounted in the valley between the cylinder heads, beneath the intake manifold, feeding a set of very specialized fuel injectors with super-high-pressure of about 2,175 psi. That has huge implications for the aftermarket performance and tuning world, which will undoubtedly require time to adjust to the new configuration.

The LT1’s oiling system is also new and includes oil-spray piston cooling, which was previously only used on the supercharged LSA and LS9 engines.

The system uses a new, variable-displacement oil pump that enables more efficient oil delivery, per the engine’s operating conditions. Beyond LT1’s greater performance and expected fuel economy over the LS3 and even more than its roster of new features is the inescapable fact that General Motors has doubled down on the overhead-valve engine design. It wasn’t without hard consideration or self consciousness, either. Believe us, everyone at Chevrolet is sensitive to the years of criticism from pundits who cite the small-block as an archaic lump in a more sophisticated world of multi-cam competitors.

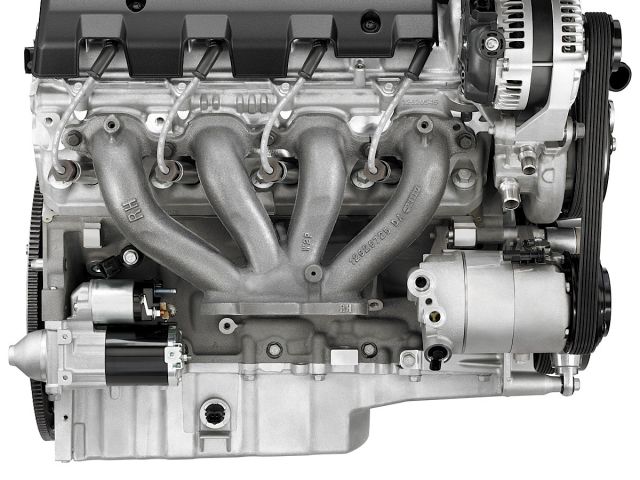

An 87mm throttle body caps the LT1’s intake manifold – which definitely looks odd without fuel injectors in it. They’re now located in the cylinder heads for the direct-injection system.

Perception isn’t necessarily reality, however, as the Corvette Racing team demonstrated during 2012. The small-block-powered C6.Rs beat Ferrari, BMW and Porsche to sweep the drivers’, team, and manufacturer championships in the production-based American Le Mans Series GT class. Clearly, an engine with a single camshaft mounted within the cylinder block wasn’t a constraint.

“The engine requirements for a production car and a race car are remarkably similar,” says Jordan Lee, Small-Block Chief Engineer and Program Manager. “In both cases, you want an engine that is powerful and efficient, compact and lightweight, and durable. That combination is what made the original small-block so successful. The new, state-of-the-art technologies make one of the best performance car engines in the world even better in the LT1.”

Right on. We can’t wait to sample the engine in the new Corvette and show some of those imports what a set of pushrods can really do!

2014 CORVETTE LT1 6.2L V-8 SPECIFICATIONS

- Engine type: 90-degree V-8 with overhead valves; continuous VVT

- Displacement: 6.2L (376 cubic inches)

- Bore x Stroke (in): 4.06 x 3.62

- Cylinder block: Cast aluminum with nodular main caps

- Main bearing fasteners: Six, including two cross-bolts per cap

- Crankshaft: Forged steel

- Connecting rods: Powder metal, 6.125 inches in length

- Pistons: Eutectic aluminum alloy

- Compression ratio: 11.5:1

- Cylinder heads: 319-T7 cast aluminum with 59.02cc combustion chambers

- Valve angles (degrees): 12.5 intake, 12 exhaust

- Intake valves: 2.13 inches (54mm) hollow

- Exhaust valves: 1.59 inches (40.4mm) hollow sodium

- Camshaft: Hydraulic-type with tri-lobe for fuel-pump drive

- Camshaft lift: 0.551-inch (14mm) intake / 0.524-inch (13.3mm) exhaust

- Camshaft duration: 200-degrees intake / 207-degrees exhaust (at 0.050-inch)

- Lobe separation angle: 116.5 degrees

- Fuel delivery: Direct-injection

- Intake manifold: “Runners in a box” design; composite construction

- Throttle: 87mm electronically controlled throttle body

- Ignition: 58X with individual coil-on-plug and iridium-tip spark plugs

- Horsepower: 450 (estimated)

- Torque – lb.-ft: 450 (estimated)

- Max. engine speed: 6,600 rpm (fuel cutoff)