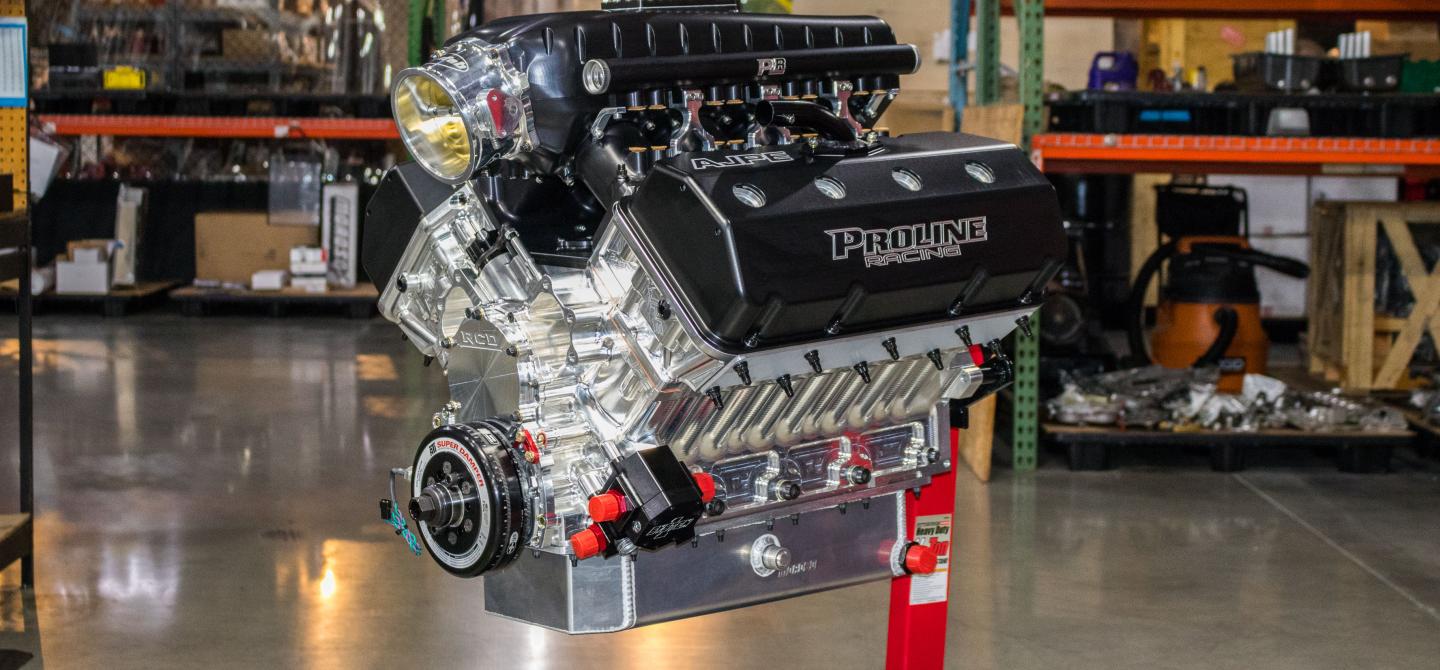

Being competitive is no easy feat in the cut-throat Radial Vs. The World class, but that’s exactly what Project BlownZ06 is designed to do. The 2017 Corvette, built by the fine folks at PMR Race Cars in California, recently made its debut and took home a win in the NMCA’s Radial Wars class at the season opener in Bradenton, Florida. To win in such a competitive class requires a top-shelf powerplant; in our case, a supercharged 548 cubic-inch Hemi designed, assembled, and tuned by the experts at Pro Line Racing in Ball Ground, Georgia.

The first article on this engine dropped recently, which covered the short-block buildup and behind-the-scenes details from the Pro Line team.

No engine can win races without an induction system, however, and that’s where BlownZ06’s powerplant really begins to shine. Through the use of a set of Alan Johnson Performance Engineering’s Muscle cylinder heads, a set of trick rocker arms from Reid Machine, an intake from David Visner at Visner Engine Development and one of ProCharger’s finest F-3R-136 superchargers, BlownZ06 became the quickest radial-tire-equipped supercharged car on the planet in only its second outing at the racetrack.

Induction Components Win Races

As we discussed in the short-block article, the Pro Line engine-building team has tested these Hemi parts in a wide range of applications. The main focus of using this design is the overarching theme of strength; as the Hemi platform from AJPE has been proven over the years in Top Fuel, Funny Car, Top Alcohol, and other racing classes, it’s no secret that the engine can handle just about any kind of power level without a hiccup.

With the solid foundation in place, let’s take a look at the top end components which help to make this engine so successful.

Front-and-center up top on this engine are a set of Alan Johnson Performance Engineering’s P8 Hemi cylinder heads.

The AJPE Muscle heads combine with our Visner/PLR intake manifold to suck down 50-plus pounds of boost from our ProCharger F-3R-136.

“It is the Muscle Head IV design with a P8 port program. The head was developed for us with larger intake ports than the normal P3 Outlaw version, and as far as I know, we are the only ones currently running these. The P8 heads were spun off of the P7 and P9 NHRA heads and ports that we had input on, and own the rights to. While the P8 head is available to the public, it’s only usable in Outlaw classes due to the 2.490-inch x 2.020-inch valve sizes,” says PLR’s Chris Jones.

Boost pressure can have a tendency to cause turbulence inside the manifold, so the intake was developed with an abnormally large plenum and gradually tapered lid to counter this. Cylinder to cylinder corrections are minimal with this design. The transitions from the plenum, to the runners, to the ports are gradually tapered, but start out very large to further aid with this. — Chris Jones, Pro Line Racing

The billet aluminum Muscle Heads check in at 33.5 pounds each (bare) and are constructed from 6013-T651 material, which is made in the USA. For consistency between engines, these arrive fully ported from AJPE. The heads use 50-degree intake and 55-degree valve seat angles for increased airflow and features a tubeless intake port design, which means there are no pushrod tubes to leak or fail, a common problem with other styles of Hemi heads. There are stainless one-piece O-rings in the cylinder head decks to seal in combustion pressure, and they are clearanced for 9/16-inch pushrods right out of the box.

“The chambers are pretty much standard-fare Hemi, no real trickery. Hemi engines can expel charge from the intake directly into the exhaust during overlap since the valves face each other to a degree, so there is a ledge built into the chamber between them to help negate some of the cross-talk. The larger ports create a bit of a pressurized ‘reservoir’ area, for lack of better terminology. The flow numbers on these larger port heads don’t really shatter the world, and the velocity is down when compared to their smaller versions. If you were to install these on a naturally aspirated engine they probably would lose power over an optimized design that keeps the air speed up under normal atmospheric pressure,” says Jones.

Each spring is checked prior to installation for both open and closed spring rates to ensure consistency.

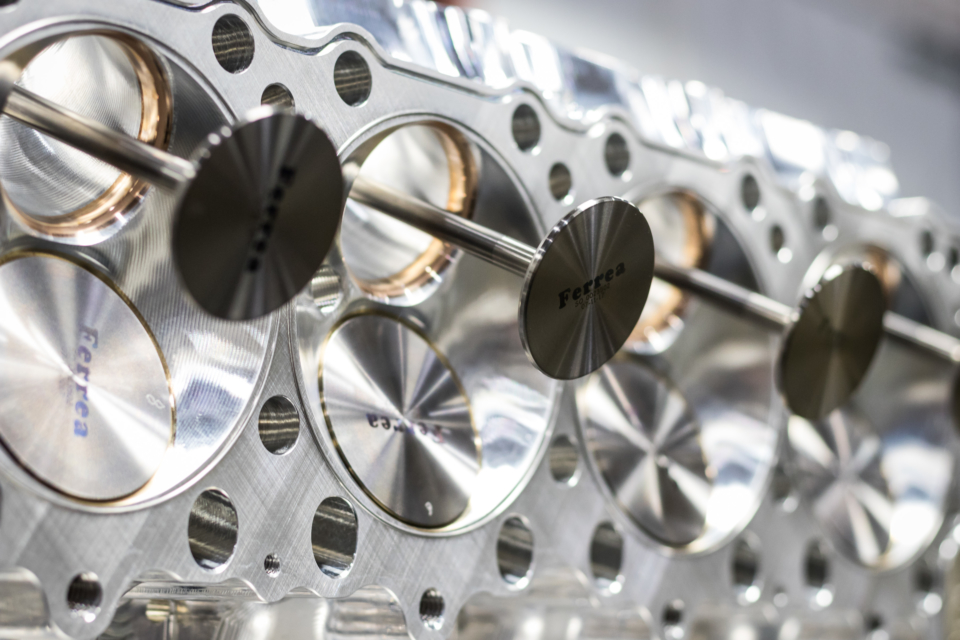

The heads are finished off with a full complement of Comp Cams gear, from the company’s monster 26700-16 spring package to its locks, retainers, and spring locators, which are all designed for this application. Comp and PLR collaborated to determine the perfect spring properties to handle the supercharged power in this engine, and came up with the 26700. It offers a 2.300-inch installed height and 1,440 pounds of open pressure to get those Ferrea valves sealed back up tight against the massive boost our ProCharger F-3R-136 makes at full song.

The Ferrea titanium valves measure the aforementioned 2.49-inch intake and 2.02-inch on the exhaust side. Just think about that for a second—a traditional small-block “street car” head would likely use a 2.02-inch intake valve. These valves are built with a high-temp alloy which is heat-treated and stress-relieved, and machined on Ferrea’s in-house machining centers.

Hot street-car-sized intake valves—in the exhaust. The Chrome Nitride-coated Ferrea valves stand up to the immense abuse put forth by the massive boost from our ProCharger.

It’s difficult to explain how much abuse the valves take in an application like this. Ferrea combats the heat with a Chrome Nitride (CrN) coating,which covers the entire valve and helps with heat dissipation on the valve guide.

EFI, Supercharger, & Gear Drive

We’ve already given you a complete rundown of the capabilities of Fueltech’s FT600 engine management system that we’re using in BlownZ06. A quick recap: this system can do everything we need and more—it’s capable of driving our methanol-injected machine deep into the three-second zone in the eighth-mile, yet could be used on a relatively-tame street car as well. The modular construction of the unit features the ability to program in 32 outputs and 20 analog inputs to log and operate any sensor you can dream up, while remaining small in footprint and user-friendly.

Our F-3R-136 sans volute. The billet impeller wheel is front-and-center, and in the background you can see the CDS gear drive unit, which is driving our Aeromotive Spur Gear fuel pump in this application.

Procharger’s F-3R-136 supercharger needs no introduction. The company’s F-series supercharger line has powered dozens of champions over the last two decades, and the F-3R-136 is one of the dominant players in the centrifugal supercharger game. With a monster 12-inch volute and 3,000-plus-horsepower capabilities, it will serve us well in this application—until we decide to switch to the big-dog F-3X-143 unit. That’s coming soon. We’ve already accomplished two of our goals in just two events: to become the quickest radial-tire-equipped centrifugal-supercharged car on the planet, and winning a race. Adding the larger supercharger will put another 300-400 horsepower under the hood to help take us to that next level.

Our previous racing efforts with a supercharger have been bolstered by the use of one of Component Drive Systems’ supercharger drives from Chris Alston’s Chassisworks.

Although we are unwilling to disclose the exact gear ratio provided by the Winters Performance gears inside the drive, we will say that the supercharger is spinning somewhere around 68,000 rpm to make about 50 psi of boost pressure. Although the CDS gear drive is capable of driving many external accessories such as a vacuum pump, water pump, power steering pump, and more, we’re simply using it to drive our Aeromotive Spur Gear fuel pump, designed specifically for Pro Mod and Nostalgia Funny Car-style applications, where fuel demands are robust.

We’re not sure which is prettier: the ProCharger F-3R-136 or the Component Drive Systems gear drive unit.

The CDS gear drive block plates were custom-engineered by Chris Alston, Jr. for the AJPE Hemi application. Working in conjunction with Pro Line Racing, the CDS team designed the drive to more effectively distribute the loads of the gear drive and supercharger across the entire front of the engine block. In some applications, the CDS gear drive only captures the lower part of the block, however in this application, the gear drive block plate is captured completely to the block, providing additional strength to prevent block and cam tunnel shearing.

On top of the heads sit a set of Reid Machine’s trick shaft-mount rocker arm assemblies. Valvetrain stiffness is absolutely critical—as one might imagine—with 50-plus pounds of boost pressure entering and exiting the engine, and to that end the Reid pieces have an intense focus on construction and material selection.

As they are used in Top Fuel, Funny Car, Blown Alcohol and Pro Mod, as well as in engines like ours, Darrell Reid and his team have determined what works effectively and incorporate certain features into every set of rockers.

This rocker arm system from Reid Machine is designed to do one thing—withstand massive abuse from the elevated power levels of a super- or turbocharged Hemi powerplant. Darrell Reid tells us these have been over-engineered to the nth degree, in order to ensure durability at the racetrack.

Reid rocker assemblies are an I-beam design, constructed from solid billet 4340 steel and are heat-treated for longevity. Each rocker offers pushrod oiling through the adjusting screw to ensure pushrod tips stay cool and lubricated. The rockers are designed with the latest Mastercam CAD/CAM software to fit each particular cylinder head configuration, and Reid prides itself on offering components which are optimized to provide the perfect location for the roller over the valve tip.

“These are shelf-stock rockers for the Alan Johnson Muscle cylinder head,” says Darrell Reid. “We have over 600 sets of our rockers in operation. We are proud and humbled to have been a part of the last five years of championships in Alcohol Funny Car, and Alcohol Dragster with our products.”

We used 1.70:1 intake and 1.65:1 exhaust rockers, spec’d by Pro Line, to maximize camshaft performance. Reid offers rockers for 392 and 426-based Hemi engines, and each set of Reid rockers is built specifically for the application.

“We have verified our ratios to be accurate,” says Reid. “This way the racer is sure they are getting accurate camshaft lift. We engineer these products to be trouble-free, and one racer has described them to me as ‘bulletproof.’”

You’ll be able to check out the Reid rockers—up close and personal—in an upcoming article, as we’ve made the trek to the company’s California shop to see how they are built from scratch. The rockers are covered in—what else—but a set of PLR/AJPE billet valve covers emblazoned with the PLR logo.

Jesel .937-inch-diameter keyway lifters send the Trend Performance pushrods upward. The tool steel Jesel lifters incorporate Diamond Like Carbon friction-reducing coatings on the bodies, oil-pressure-fed matched roller bearings, and a keyway pin that works with Jesel’s bronze keyway bushings to keep the lifter in place during engine operation. The oiling circuit ensures that the pushrod, roller, and cam also receive the proper amount of lubrication to ensure longevity. A nice feature of the lifter design is that through the use of the keyway, extra weight in the form of dog-bones or tie bars isn’t present.

These bigger centrifugal blowers are actually more efficient in upper RPM ranges than a positive-displacement blower. — Billy Godbold, Comp Cams

The pushrods, Trend’s latest and greatest, actually came from the company’s Quick Ship pushrod program. Despite the fact that they are completely custom to our application, Trend was able to get them out to us quickly. The 9/16-inch pushrods have a custom-to-our-application clearance for the lifter end, and are full tapered .187-inch wall thickness.

On the lifter end, there is a 5/16-inch ball, while the rocker end uses H13 Tool steel .187-inch radius cups. The intake side uses 11.930-inch length pushrods, while the exhaust pushrods are 11.090-inch long.

What does Quick Ship mean? One- to two-day turnaround on full custom pushrods, an achievement of which the Trend team is quite proud.

“The Quick Ship program has been in place for about 16 years now,” said Trend Performance general manager, Steve Rhodey. “It’s essentially a custom, one-piece pushrod [or set] with a 24- to 48-hour turnaround time. And that covers everything from a small-diameter, heavy-wall pushrods, all the way to a large-diameter, heavy-wall pushrods with multiple ends and clearance options.”

“We’ve got Pro Mod and Pro Stock drivers that are utilizing this program,” adds Rhodey. “A lot of times they’ll test during the week and hurt something before their race on Friday or Saturday. We’ve had situations where pushrods were ordered at 2:00pm on a Friday and we had them built and shipped out to the race track for an early Saturday AM delivery. We probably do that a half-dozen times a month.”

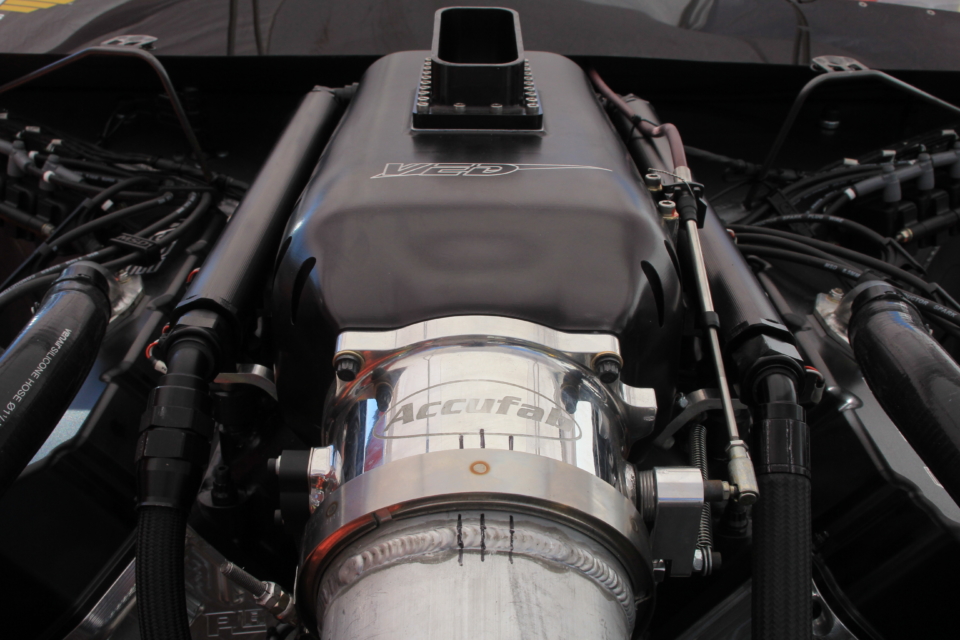

David Visner of Visner Engine Development has worked very closely with Pro Line Racing to develop the company’s billet intake manifold configuration to work with the AJPE cylinder heads. The solid construction means that no matter how much boost we throw at this engine, there will be no fears of intake manifold failure.

“The large plenum volume helps to calm down the air inside the plenum, and maximize the cylinder-to-cylinder distribution,” says Jones.

“Compared to turbos, roots, and screw blowers, the centrifugal supercharger poses a bit more of a challenge trying to counter the large volumes in the intake tract lower in the rev range. Coupled with the larger cams that superchargers tend to need in order to run well, we don’t produce the bottom end torque that an equivalently-sized engine with smaller head and intake volumes can. Being that this is a dedicated racing engine, this problem can be overcome with the proper transmission, converter, and rear gearing package though.”

It’s all the rage these days to use this chimney-style burst panel in the intake manifold. This Visner manifold was developed in conjunction with the Pro Line Racing team based on their real-world feedback as to what performs at the track. Note the near-five-inch (125mm) Accufab flanged throttle body.

The Visner intake uses machined-in fuel injector placement, and a super-strong fuel rail mounting system, so the chance of injector O-ring failure is greatly reduced, which is a large concern for an engine like this that is pushing extremely high fuel pressures. There are five mounts per rail, which helps with the rigidity of the mounting system and prevents movement. The manifold features a top and bottom half which are mated with an O-ring, and the runners themselves also feature O-ring connections. There is a burst panel mounting system up top, which releases the pressure in the event of a backfire to prevent damage to the plenum itself.

“Boost pressure can have a tendency to cause turbulence inside the manifold, so the intake was developed with an abnormally large plenum and gradually tapered lid to counter this. Cylinder to cylinder corrections are minimal with this design. The transitions from the plenum, to the runners, to the ports are gradually tapered, but start out very large to further aid with this. The runners are shorter than normal to allow for the larger plenum area as well, and to fit within dimensional constraints.

One of the bigger concerns with the intake is strength. High boost can cause a thin intake to balloon out, crack, and ultimately fail over time. This one is built with stout wall thicknesses in the critical areas to keep that expansion to a minimum and eliminate cracking. Even with that, we use the burst plate to combat against a backfire or other mishap that can lead to a sudden surge in manifold pressure,” says Jones.

Camshaft Selection

Camshaft design for this big-power bullet is a collaboration between PLR and the wizards at Comp Cams, as cam designers Billy Godbold and Dean Harvey dove deep into this project when their assistance was requested. There are hundreds—if not thousands—of Pro Mod-style roots-blown engines out there, but really high-end Pro-Mod-style centrifugally-supercharged Hemi engines are not as common yet. So this presented a challenge to the Comp Cams team and Pro Line.

“On these huge gear-driven centrifugal Pro Mod blowers, they are much more like a large positive-displacement blower, in they are much more linear than a typical belt-driven centrifugal supercharger. Most centrifugal systems are just not comparable and these are actually more efficient than the positive-displacement systems,” says Godbold.

There is no doubt that with over .500-inches of lobe lift on both the intake and exhaust sides of this camshaft, that it’s a bumpy stick. Pro Line Racing enlisted the assistance of Comp Cams’ Billy Godbold and Dean Harvey in spec’ing it out for us.

The key is striking a balance between upper-end RPM efficiency, valvetrain stability, valve-spring life, and ensuring there is adequate power to accelerate the engine down low before there is a significant quantity of boost.

“Looking at valve timing, you have to look at exhaust pumping losses and exhaust opening closely. You don’t have the same pressures as a nitro application because the alcohol burns much more quickly so pressure drops sooner. The air these engines ingest and the power they produce is absolutely overwhelming! With the air capacity these can handle, losing too much intake charge during overlap is not a major concern, but you do have to look closely at not only piston-to-valve, but also valve-to-valve clearance on the large Hemi grinds,” says Godbold.

As a result of this, Godbold and Harvey have to pay close attention to the camshaft’s specifications to ensure the engine doesn’t pump all of the boost right out the exhaust. Ultimately, the camshaft that was chosen is just a mild bumpstick: it measures 299/306 degrees of duration at .050-inch, uses a 119 Lobe Separation Angle, and pushes the valves open with .515-inch intake and .500-inch exhaust lobe lift—that’s .875-inch lift at the valve on the intake and .825-inch lift on the exhaust side!

Fasten It All

Of course no race engine is complete without all the fasteners which—while not the major parts like heads or a crankshaft—are just as important to the overall package. As with every build we undertake here at EngineLabs, a full complement of ARP fasteners are used throughout the engine, from the flexplate bolts to the H-11 tool steel head studs, to the nuts holding down the valve covers.

ARP’s fasteners have long been the enthusiast’s choice when it comes to securing engine parts in the proper places, and for good reason: the company has invested its efforts into developing components which prevent problems from occurring. The made-in-the-USA fasteners use the latest in metallurgical technology to ensure that clamp loads remain consistent, fastener strength is paramount, and there is consistency from part to part, which is crucial in a monster-power application such as BlownZ06’s ProCharger-boosted Hemi.

In this engine, we used head studs manufactured from ARP’s Custom Age 625 material, which is a stainless-steel alloy with a high tensile strength of 260,000 psi. It’s harder than ARP’s traditional ARP2000 material and offers a much higher clamping load capability—key on our big-boost Hemi. The material is also completely resistant to atmospheric corrosion and oxidation.

Engine Completion Parts

With the major hard parts under control, it was time to look at the other pieces that make this assembly of parts into a complete engine. Billet Atomizer 700 pound-per-hour injectors are used in a dual-injector-per-cylinder configuration for a total of 16 squirters providing the fuel. You can read more about those in this tech article.

6061-T6 billet aluminum is the base for the construction of Accufab’s 125mm MAX throttle body—yes, that’s just shy of five inches across of throttle body area that sucks down the 50-plus pounds of boost from our ProCharger. The stainless-steel split-shaft design uses four ARP screws to mount the blade to the shaft, and features a ferrule machined onto the inlet edge of the body for easy inlet pipe connection; this requires one of Accufab’s Completion Kits which includes the V-band clamp and matching ferrule. On the back side of the throttle body, an O-ring groove is machined into the face to provide a leak-free seal to the intake manifold.

Spark comes from the FuelTech FT600 through a set of MSD 8.5mm Super Conductor wires designed specifically for the Hemi engine in race applications like ours. These wires need to be built, but that was perfect for us since we were able to tailor them to our FuelTech coils and ensure the perfect length when they were complete. NGK 6061-10 spark plugs are the standard for use with Hemi combinations.

Developing a flexplate [P/N FPS148] to withstand the enormous power from a typical Pro Mod is a task that was not lost upon Meziere Enterprises, owned by brothers Don, Mike, and Dave Meziere.

“Every flexplate we make is billet and one-piece. It’s a safer plate. We did some prototypes that were two-piece, but we couldn’t get the precision and we couldn’t get the strength,” Don explains.

“We start with a 20,000-pound bar of 4340 steel that’s cut up into little pieces and subsequently CNC-machined from there. It’s about six CNC operations plus heat treating to get it where we want it. The actual CNC run time on each plate is well in excess of two hours. It’s the long way around the block to make them this way, but we feel it’s also the best way.”

It takes upwards of two hours of machining time to create one of Meziere’s True Billet flexplates. These start out as a 20,000-pound billet chunk which is then cut into slices and finally turned into the machined goodness seen here. These are heat-treated for strength and durability.

The plate is one-piece, with each machining operation tightly controlled. They can keep the concentricity within .005-inch to provide a flexplate which has virtually no runout. And since there is no separate ring gear welded to the plate, the gear teeth are cut during the CNC machining process for superior consistency and strength. Each Meziere Pro Mod Extreme Strength True Billet flexplate is certified to the SFI 29.2 specification.

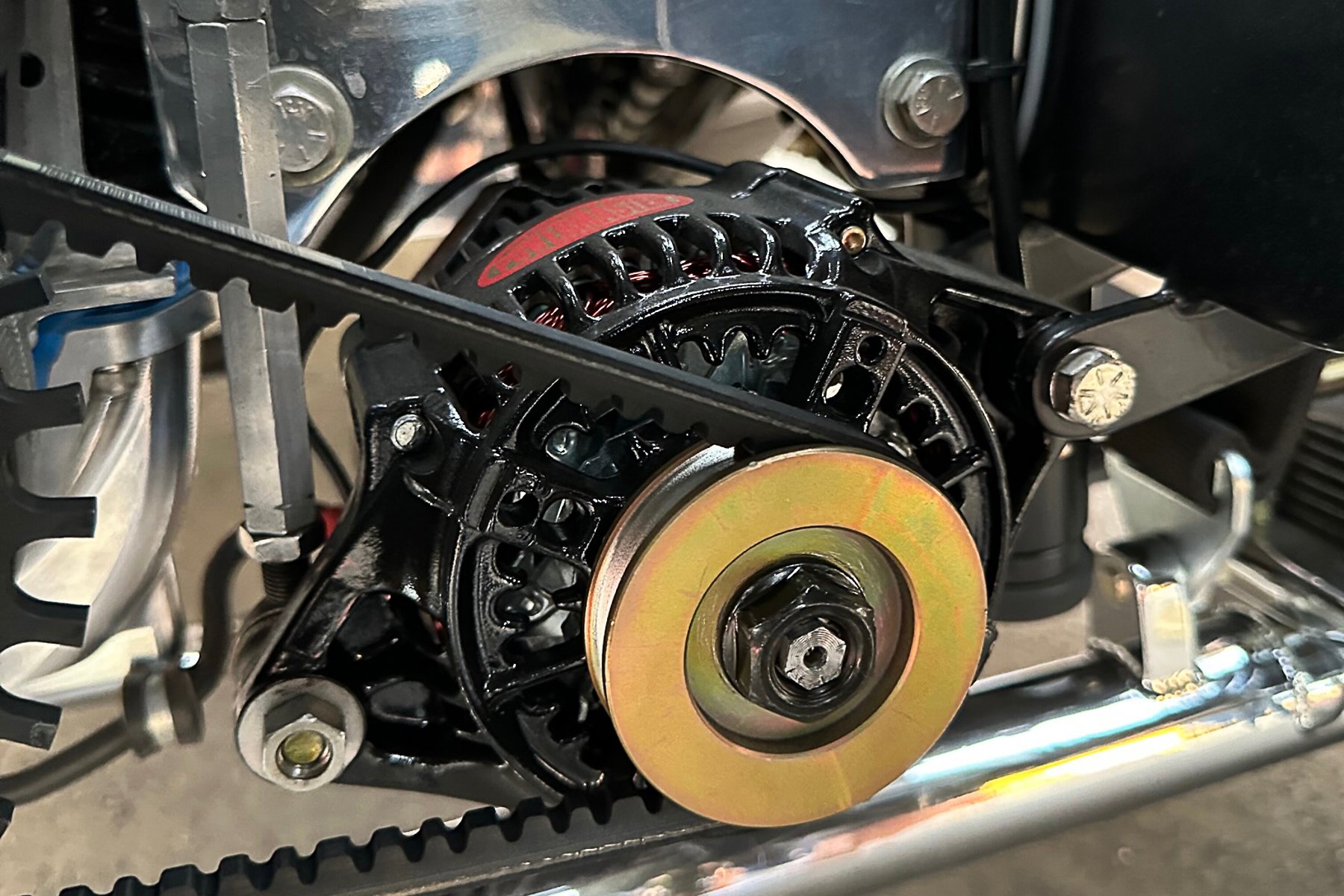

Typically, Top Fuel and Funny Car engines use an external removable starter, but with more and more of these engine combinations finding their way into Outlaw-style racing, the need to have a permanently-mounted starter is critical; according to Meziere, the AJPE team has stepped up to offer this provision—which allowed them to build a matching starter for the True Billet flexplate for this application.

“In years past we’ve had to deal with starters on the midplate, but Alan Johnson has done everyone a huge favor by putting a feature on the side that uses a Chevrolet-style starter. To give these racers the most strength we could, we changed to a 10-pitch gear tooth profile,” says Meziere. “It’s a taller, stronger gear profile, but like any gearset, you have to match up the pinion with the ring gear, and we had to move the centerlines closer to each other. The guys at PMR had to trim the starter nose block to get the starter lined up, and it was perfect.”

As a result of this research, the Meziere team also created a couple of new part numbers for this starter configuration [P/N TSS083 for passenger side and TSS070 for driver’s side applications] and can offer them to anyone seeking a premium starter for an application like this.

One item that he touched on during our discussion was the importance of wire size when it comes to feeding a starter, especially one that has to start an engine such as this, with a big supercharger and relatively high compression onboard.

“We’re finding a lot of cars that are not wired adequately for the type of load that these blown engines put on them. It takes a lot to crank them; I get guys with brand new cars calling me to say that the starter is underperforming, but the information is readily available. If you look at the amperage load and the distance you need to run; most of these cars need 1/0 cable, and some even need 2/0 cable, which is really heavy, but it’s crucial to the performance of the starter,” says Meziere.

Sealing It Up

Although many of this Hemi’s mating faces are sealed with O-rings (the intake, oil pan, and front cover all use this method) we still need to seal the cylinder heads to the block effectively. To do so, a set of SCE Pro Copper head gaskets designed specifically for use with the Pro Line/AJPE Muscle heads were chosen.

These annealed copper gaskets are built specifically for Pro Line Racing, have 4.500-inch bore openings, and measure .081-inch thick. To use the Pro Copper gasket, stainless O-rings are installed into the block, with a corresponding receiver groove machined into the cylinder head. SCE’s Pro Copper header gaskets are also onboard; these feature an embossment around each port, which contacts the weld on the inside of the header tube to provide a leak-free seal when the fasteners are clamped tight.

Now that we have all of the parts and pieces assembled for this monster powerplant, we’ll wrap up this build in the last article of the series. Stay tuned right here for more…