The original FAST [2] EZ-EFI system boasts plenty of features that make carburetor-to-EFI swaps so attractive these days. Among those are: self-tuning strategies that eliminate the need for a laptop and advanced computer skills; fast startup procedures and continuous self-learning capability; minimal hardware and electrical connections; and a self-contained throttle body with all the necessary injectors and sensors to facilitate an easy installation.

[3]

[3]FAST offers its EZ-EFI 2.0 kits with a number of options, including different fuel pumps and a stand-alone ECU module for retrofitting on engines with multi-port injection. Shown above is the base kit that includes the throttle body, ECU, wiring harness, 02 sensor, hand-held programmer and necessary hardware. Optional FAST valve covers and air cleaner can be used to dress up the engine bay.

Now comes the new EZ-EFI 2.0 system [4] to improve on those original features and add considerable more function as well as eye-appealing appearance. More important to racers, the new system will work with engines capable of 1,200 horsepower. Most of the entry-level EFI swaps are good only to 600 horsepower.

The big question, of course, what’s in it for the racer?

The majority of carb-to-EFI swaps are demonstrated on street vehicles or off-road vehicles, simply because the benefits are indisputable when compared to carburetors. Consistent and precise fuel delivery enhances drivability, lowers emissions and boosts fuel economy, just to name a few. And off-roaders love EFI conversions because they eliminate float-level problems when driving off-camber or climbing steep hills. Granted, EFI requires a different — and sometimes intimidating — approach to tuning, and it’s more expensive. But cost and horsepower have always been awkward partners in improving performance — that’s a given.

Tuning through advanced electronics

The tuning challenges, however, can be subdued with sophisticated technology that handles all of the work and even looks for ways to optimize performance on its own, regardless of the user’s input. That’s the primary advantage of an EZ-EFI system.

“You can plug it in and drive without knowing anything about it,” stresses Brian Reese, lead engineer at Comp Cams [5], the parent company for FAST.

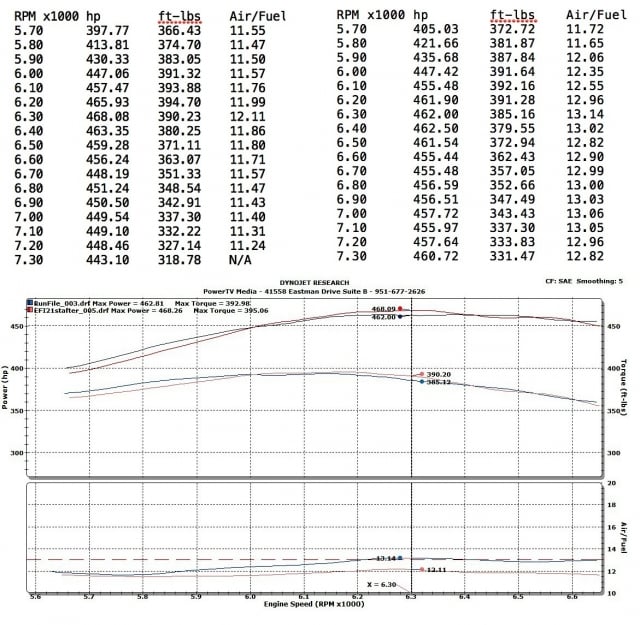

The EZ-EFI 2.0 conversion will work on just about any carbureted engine. This project focues on Mark Rapp’s 1970 Nova, which runs in the low 9.80s with a 406ci small-block equipped with a single 4-barrel atop an Edelbrock Super Victor intake. Baseline run on the Power Automedia Dynojet chassis dyno produced a best of 462.5 horsepower at 6,400 rpm with peak torque of 392.2 lb-ft coming in at 6,100 rpm.

EZ-EFI 2.0 For Engine Swaps

The EZ-EFI 2.0 ECU and programmer are available as a stand-alone kit (PN 30405) for retrofitting on engines with existing multi-port EFI engines, such as a salvage-yard LS that’s going in a street-rod project. With the customer-supplied injectors, there is basically no horsepower limit on the electronic controls. The interface still doesn’t require a laptop computer or programming skills, and the ECU will provide the same simple tuning and self-learning features.

EFI programming is designed to provide optimum fuel delivery over a wide rpm range, at different operating temperatures and under various throttle loads. Racers, especially those on the drag strip, focus on making the most power in a high but narrow rpm band under wide-open throttle (WOT)– and therefore modify and tune the carb for the best performance under strictly defined conditions for each race. When the conditions change, such as an ambient temperature increase during the day, then the carburetor needs to be adjusted accordingly.

“Bracket racers and anyone who needs consistency can utilize the EZ-EFI system,” says David Page of FAST. “The system will take into account atmospheric conditions. The owner doesn’t have to make changes based on the weather. A carburetor is static in tuning, unless you physically change the jets or air bleeds.”

Just how does the FAST system work?

“It’s got a sophisticated algorithm of inputs where it takes all the different conditons of the engine, such as rpm, throttle position, oxygen-sensor reading,” explains Reese. “Then it runs through a series of tests to see, is this a point that needs learning, or is this a transient point that doesn’t need learning? Then it decides if it’s good feedback or not. If it’s good feedback, it uses that to adjust the fuel delivery.”

Getting started

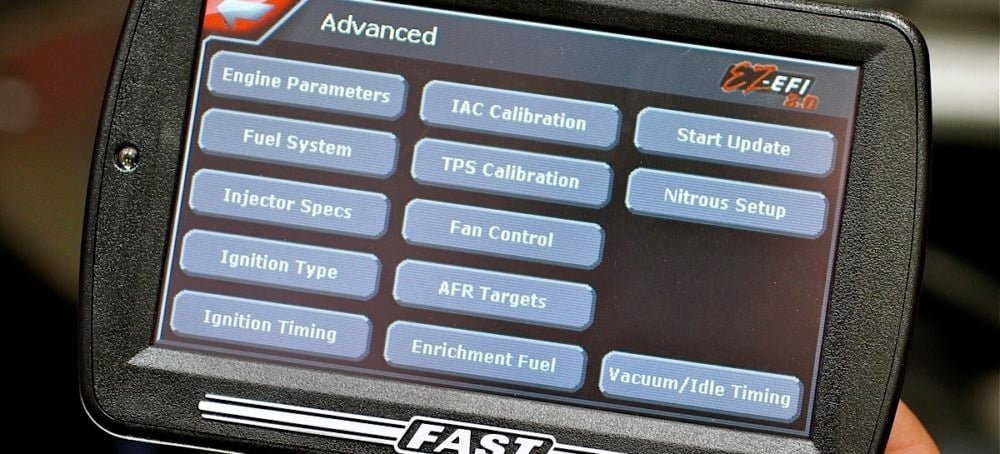

The EZ-EFI 2.0 ECU is programmed with base maps to safely get the engine started and allow the user to make preliminary adjustments to the fuel regulator, throttle-position sensor, idle-air control and ignition timing. From there, the computer will continue to monitor driving styles and conditions and adjust the tune accordingly. The baseline tuneup will generally be on the safe side to avoid hurting the engine. However, the user can go into the Advanced menu to change a number of parameters, including fan control and air/fuel ratios for idle, cruising and WOT.

[9]

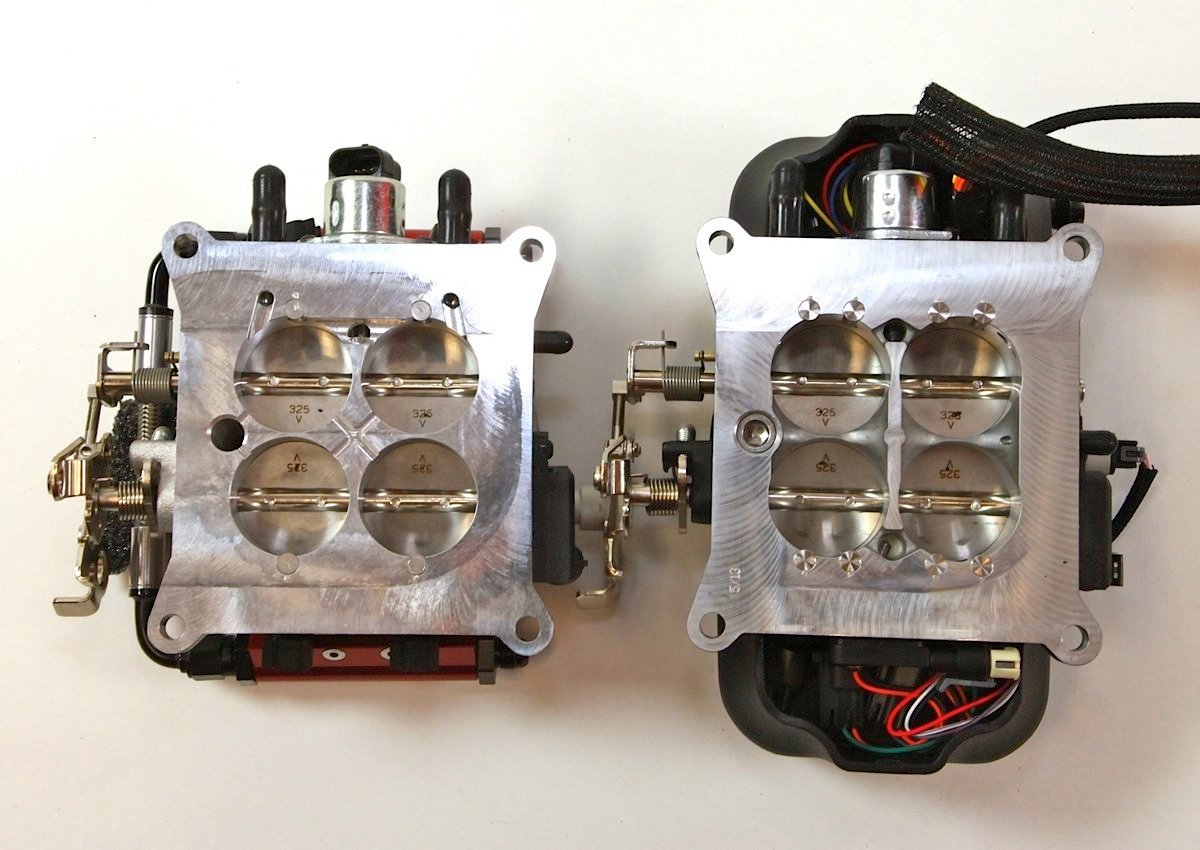

[9]Shown are comparison views between the original EZ-EFI throttle body and the 2.0 model. The base throttle body has four injectors while the 2.0 version has eight. All the necessary sensors are contained in the throttle body, except for the engine-coolant sensor. Also shown below is a comparison between the original ECU and programmer, left, with the 2.0 version. Note the LED indicator lights on the ECU and the larger, full-color touch-screen programmer on the latest generation EZ-EFI.

You can plug it in and drive without knowing anything about it.–Brian Reese, Comp Cams

“For the guy who wants to play with it, you can go in and set the air/fuel targets,” says Reese. “For example, a racer says his engine make peak wit 13.2:1 at WOT. The setting on the EZ might for peak power might be 12:7, which is a little rich and safe. He can go and dial in 13.2:1. And same on the ignition. You can plug it in and it’ll have a save curve from the start, or you can go in and change the total timing or the shape of the curve.”

The basic FAST EZ-EFI 2.0 kit comes with the throttle body, ECU, wiring harness and handheld programmer. The base kit (PN 30400) can also be ordered with a choice of in-tank (PN 30401) or in-line (PN 30402) fuel systems, or the user can fashion a fuel delivery setup using a variety of aftermarket pumps, hoses and fittings.

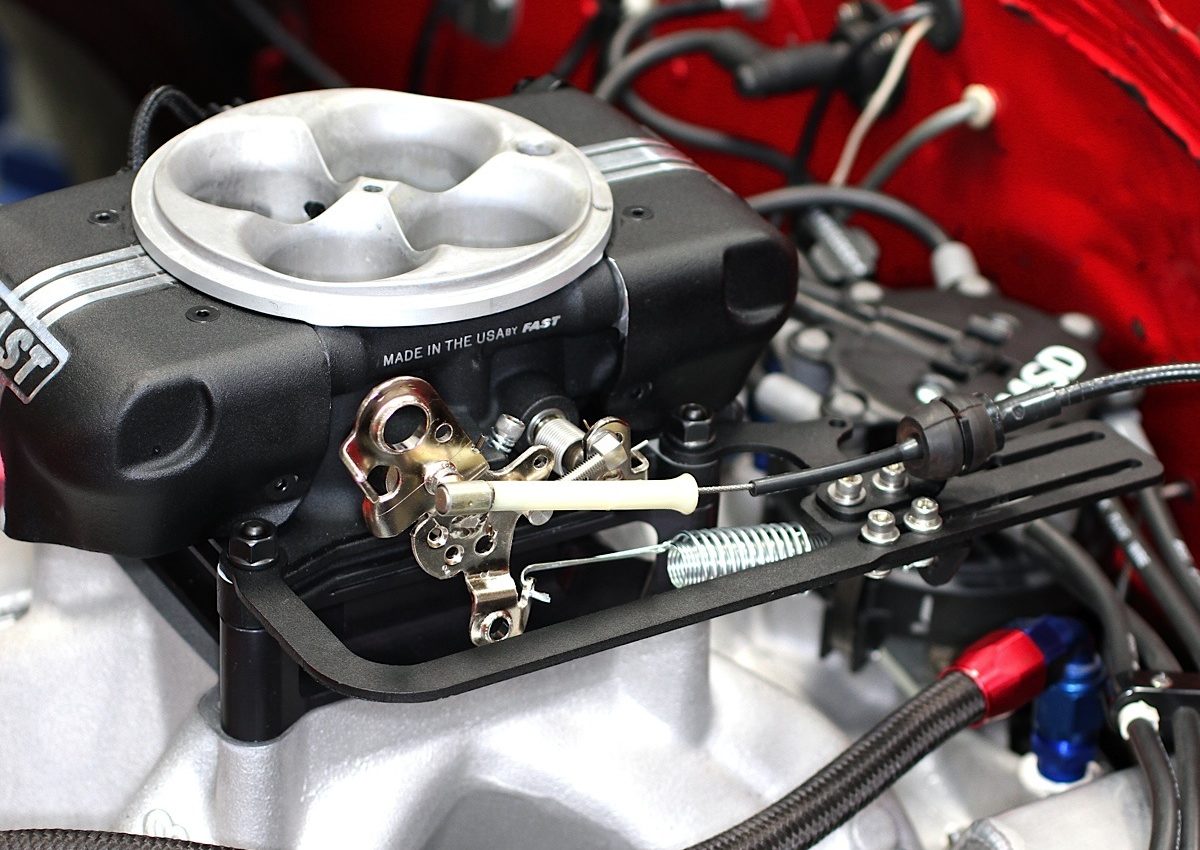

With the throttle linkage and fuel lines disconnected, the carburetor is removed and replaced with the EZ-EFI 2.0 throttle body. FAST supplies a a new bracket that supports a variety of linkage and transmission kickdown needs.

Even easier on a racecar

This project followed the installation of a EZ-EFI 2.0 on a 1970 Nova owned by West Coast drag racer Mark Rapp. The engine is a 406ci small-block with a 12.3:1 compression ratio, Dart [15] Pro 1 230cc cylinder heads (2.08/1.60 valves), a Comp Cams solid roller camshaft (276/284 duration at .050 and .630 lift), Edelbrock [16] Super Victor intake and Lemons [17] step headers. With a single 1050 cfm carb modified only with jetting and air bleeds, the car runs in the low 9.80s. On its baseline dyno run, the Nova pulled 462.5 horsepower at 6,400 rpm. Peak torque was 392.2 lb-ft at 6,100 rpm. The air/fuel ratio varied between 12.35:1 and 13.14:1 between 6,000 and 6,900 rpm.

The ECU can be mounted in the engine bay or inside the cab. The preference for this project was under the dash, close to the passenger-side kick panel. The firewall already had a clean and organized appearance. Two existing holes were enlarged (the kit comes with a 2-inch hole saw and wire-harness grommet) to accommodate the FAST wiring harness. Separate holes were drilled to mount the ECU. Positive and negative power lines must be connected directly to the battery. This racecar sports a trunk-mounted battery, so the power lines were routed under the car to the truck and attached, as required.

The Nova’s sanitary fuel system helped make the swap easier than with a factory setup. The fitting were disconnected and the existing fuel pump was removed. The FAST inline pump was mounted in a convenient location and a new feed line from the pickup was installed.

Installation of the EZ-EFI 2.0 on the racecar was very smooth and quick, thanks to the clean engine bay and an easily accessible fuel cell and convenient fuel pickup location. Such a swap on a street machine may be a little more involved when working with a stock fuel tank and around the plumbing and wiring associated with an engine that could have A/C and other accessories. An installation of an original EZ-EFI kit on a ’60s Chevelle can be found here [25] for additional tips on installing fuel lines and the wiring harness.

Critical O2 sensor mounting

Key to the success of any EFI kit is the wideband O2 sensor that monitors the air/fuel ratio. The kit supplies an installation bung that must be welded to the exhaust systems — either on a header collector or standard exhaust system downpipe. If you don’t have access to a welder, then it’s advised to drive the vehicle to a muffler or speed shop to have the bung installed before starting any other work on the fuel system. The bung can be capped for the drive home. Also, if the O2 sensor is mounted on a header collector, FAST recommends that it be located at least 12 inches away from the outlet.

[26]

[26]The EZ-EFI 2.0 is designed to run either with a return fuel line or with a returnless setup. The fuel inlet line runs from the regulator to the forward port on the throttle body. The return line flows from the rear port back to the tank. A vacuum reference line also runs between the throttle body and the regulator. If a returnless system is preferred, the forward port would be plugged and the fuel inlet would be mounted in the rear port. The return line on this project took advantage of a dedicated fitting on the fuel cell (see below). Both fuel lines were routed under the floorpan to the engine bay. Note the position of the fuel-pressure sensor, which is mounted on the return line. Also note that race rules prevented the regulator from being mounted on the firewall.

“A big cam can cause reversion,” explains Page. “If the O2 sensor is too close to the outlet, there can be a false-lean reading.”

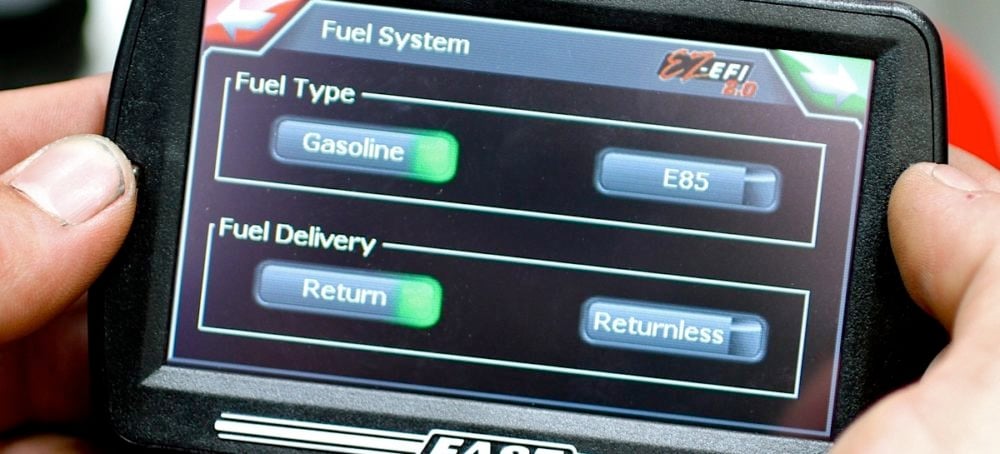

The user also has to decide between fuel system with a return line, or a single-line returnless sytem.

“Really, the only advantage to a returnless system is that it’s just one line,” explains Reese. “The downside is that you’re not cycling the fuel back, so it can get hot. The automakers did get away from return lines to cut expenses, but either way is okay. It comes down to personal preference on the hose routings.”

The system requires mounting a single wideband O2 sensor in the header collector or downpipe on a stock exhaust system. A bung is provided that can be welded on after a 7/8-inch hole is drilled in the collector or pipe. Ideally, the O2 sensor should be mounted at least 10 degree above horizontal, and it should be at least 12 inches from the open end of the collector -- so a collector extension may be necessary. With the sensor tip pointing down, there’s less chance of moisture collecting on the sensor. In the right photo, the EZ-EFI system sensor is on top. The other sensor is used by the car’s Racepak data acquisition.

Some options

The returnless option is viable due to the built-in fuel-pulse damper for precise fuel control.

“You have fuel that is incompressible,” explains Reese. “Air, you can compress. It’s like a spring, but fuel doesn’t do that. So you have to introduce your own spring into the system so there’s some cushion and accumulator effect to offset the fuel pump’s on-off, pulse-width modulation. We’re the only aftermarket system with a built-in damper, and it makes the returnless option work with no issues.”

Once the wiring and fuel lines are hooked up, the ECU is configured with the handheld touchscreen and the Setup Wizard program. The engine and vehicle parameters are first input into the program along with the type of fuel, then the engine can be started for the first time. The long cord on the handheld allows the user to work with partner in adjusting the linkage or it can used solo, such as setting the fuel regulator. Finally, the handheld is designed to work with Garmin windshield mounts, so the unit can be used to monitor live engine data or user have easy access when making adjustments.

Screenshots from top left, clockwise: Home screen with links to Setup Wizard, Live Data, Diagnostics and Advanced Tuning; choices for type of fuel include gasoline and E85 as well as deciding between return or returnless fuel system; Advanced Tuning that allows for different air/fuel ratio, ignition timing and nitrous control; and the Diagnostics menu that allows the user to check the check the system and ask for tech support.

Another user choice is fuel. The EZ-EFI 2.0 controller can be programmed to run gasoline or E85.

“One button, you pick the fuel,” says Reese. “It’s all programmed and mapped out.”

As soon as the fuel lines are tightened and all the electrical connections made, the ECU can be programmed with the engine and vehicle data for a safe startup and initial learning curve. During the first few minutes, some adjustments have to be made — such as the fuel pressure and throttle-position sensor. The air/fuel will start out rather fat to protect the engine as the ECU learns where it can make changes.

In the followup dyno test, the engine made more slightly more power and torque through the 6,000 to 7,000 rpm peak power range. With a little more time and learning on the computer’s part, or some additional custom tuning on the user’s part, the power band could be expanded. Note the richer air/fuel ratio for the second test. Again, the computer is still on a conservative pace until it gain more experience with the adjustments.

[41]

[41]Once the system had time to learn and adjustments were made to the desired air/fuel ratio, another dyno was made. As shown in the charts below, the EZ-EFI 2.0 table is on the left and the baseline is on the right. Peak power improved to 468.3 horsepower and peak torque also bumped up slightly.