[1]On a V8 pushrod engine, the camshaft is driven by the crankshaft via a set of two gears and a chain, in most cases at half the crankshaft’s speed. That’s pretty basic, but racers have several options when it comes to the drive mechanism, having used multiple gears without a chain, or replacing the chain with a rubber belt.

[1]On a V8 pushrod engine, the camshaft is driven by the crankshaft via a set of two gears and a chain, in most cases at half the crankshaft’s speed. That’s pretty basic, but racers have several options when it comes to the drive mechanism, having used multiple gears without a chain, or replacing the chain with a rubber belt.

[2]

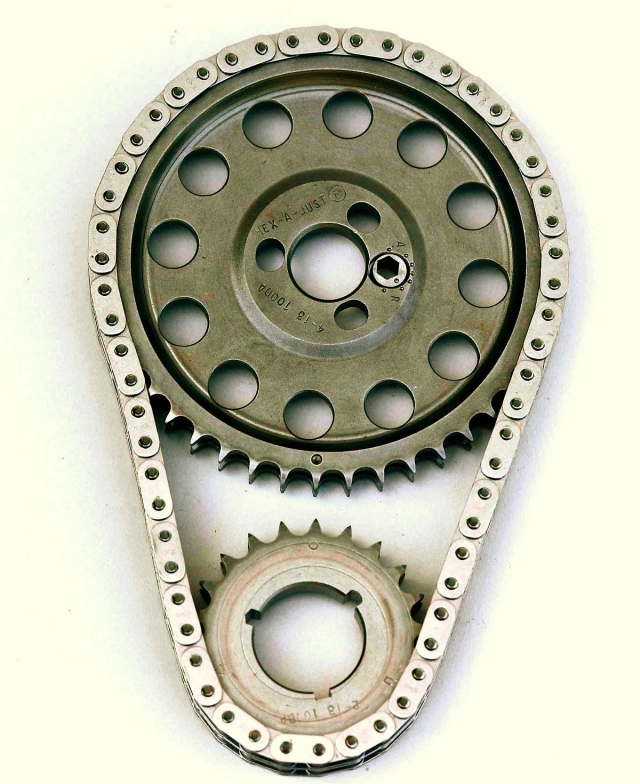

[2]This is the Cloyes part #9-3100A Hex-A-Just true roller double timing set. The crank gear has three different keyways to set the baseline cam timing. The factory keyway is the rounded one (2:00 o’clock position); 2 degrees advanced is at 10:00 (there’s a slight peak to the top of the keyway); 2 degrees retarded is the squared-off one at about 5:30.

Of the three, a belt drive is usually preferred because it theoretically lessens harmonics in the valvetrain and allows a bunch of adjustment of cam timing. There are disadvantages in both systems. A belt drive can cost upwards of $1,000 or more and is not allowed in some racing classes, whereas a gear drive can be found for about $100 but is noisy—it sounds like you have a big roots-style blower under the hood. A standard timing gear set is cheap, and even a basic single-chain system is around $20.

If you’re staying with a chain drive (which is still good, millions of small-block Chevys came that way), in a performance application, especially one using stiff valve springs, it should at least be upgraded to a double roller chain and gears for more strength, but the truly hot setup is a Cloyes [3] Hex-A-Just true roller timing set.

The Cloyes setup allows finite cam adjustment after installation, up to six degrees in either direction (advanced or retarded), which is even easier with a two-piece timing cover that is also available from Cloyes.

The cam gear comes with a thrust needle bearing. The different surfaces on each side are shown here. It installs on the backside of the of the cam gear with the black side of the bearing facing the gear hub. The silver side of the bearing should face the block. Reversing the bearing will result in excessive wear.

Why Adjust Cam Timing?

Westech [7]’s Steve Brule has pulled the Superflow handle on more engines than most of us will ever touch, so he’s forgotten more about engines and power curves than most people will ever learn — and he offers a basic explanation of adjusting the cam timing:

[8]

[8]After you pound the crank gear in place, paying attention to the keyway choices. Install the cam gear/bearing and chain. We did it the hard way by having the adjustment button in the gear while we did it, but you can do it after the cam bolts have started (but not tight).

“I hate to make generalities, but generally speaking when you advance the cam it’s gonna pick up the bottom side below the torque curve a little bit, but nothing’s free so it’s a trade off, you’re going to lose a little bit of top end,” says Brule. “And the flip side is when you retard the camshaft from its initial installation it might pick up a little bit at the top but at the loss of some power at the bottom. It’ll just kind of tilt the curve, just kind of pivot around the peak torque.”

Cloyes is a leader in supplying timing and drive components and systems to the automotive aftermarket, offering one of the most complete timing coverage in the industry. Its offerings include timing gears, sprockets and chains; timing chain tensioners, guides and dampers; three-piece timing sets, complete multi-component timing kits, timing belts, belt tensioners and kits.

We obtained a Hex-A-Just [9] kit (part #9-3100A, about $135 street price) to illustrate how its installation and use on a first-gen small-block Chevy from the stash at Westech Performance. It’s no more difficult to install the Hex-A-Just than any other timing set, you just need to read the directions and observe the tips in the photos.

With the timing mark on the bushing pointing at the middle dot on the gear, the cam timing is set at whatever you selected with the cam gear (straight up, or 2 degrees advanced/retarded). With the cam gear bolts loose, rotate the bushing with the hex wrench to adjust it further. Notice the relationship of the gear lettering and the left-hand bolt: we rotated it 6 degrees in each direction. Six degrees doesn’t sound (or look) like much, but it is.