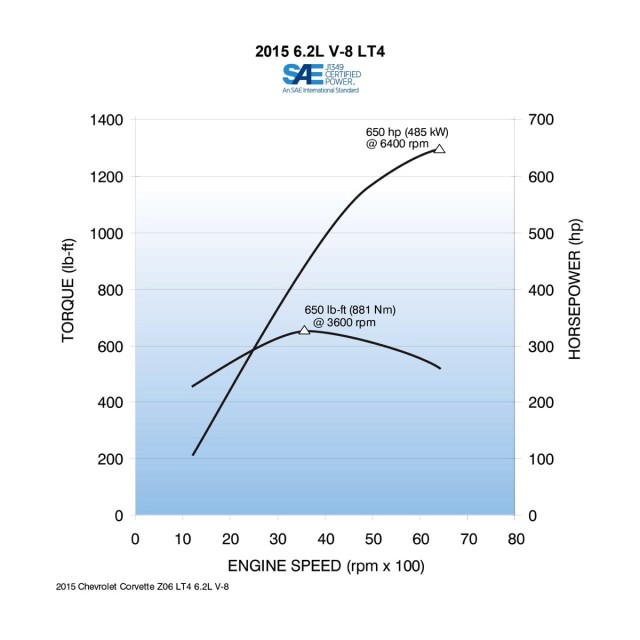

While 650 horsepower and 650 lb-ft peak torque are impressive numbers and certain attention grabbers, there’s another figure buried in the presentation for the Corvette Z06’s supercharged LT4 engine that is quite intriguing.

“The LT4 is only one inch taller than a naturally aspirated LT1 engine,” says Jordan Lee, chief engineer and program manager.

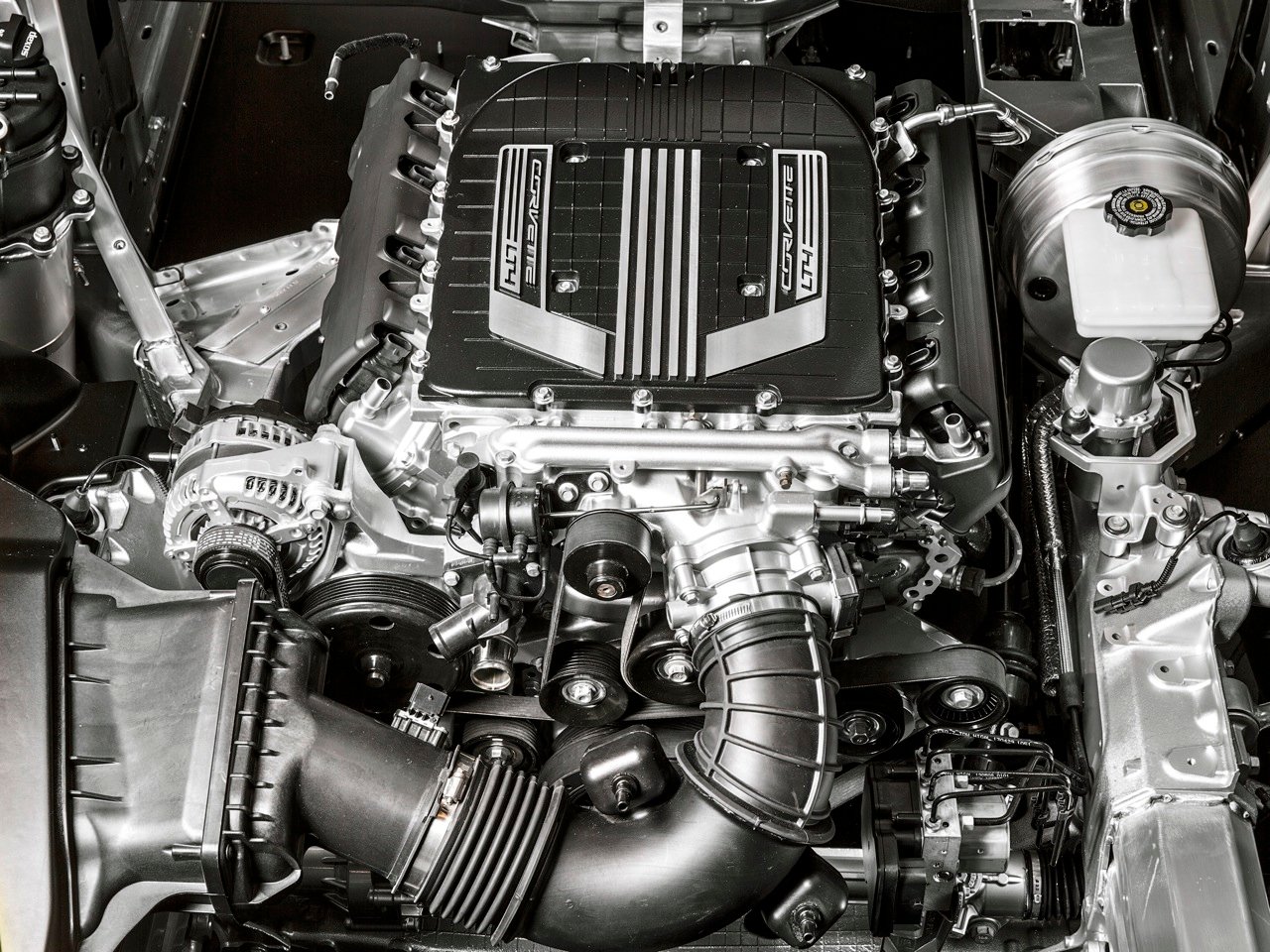

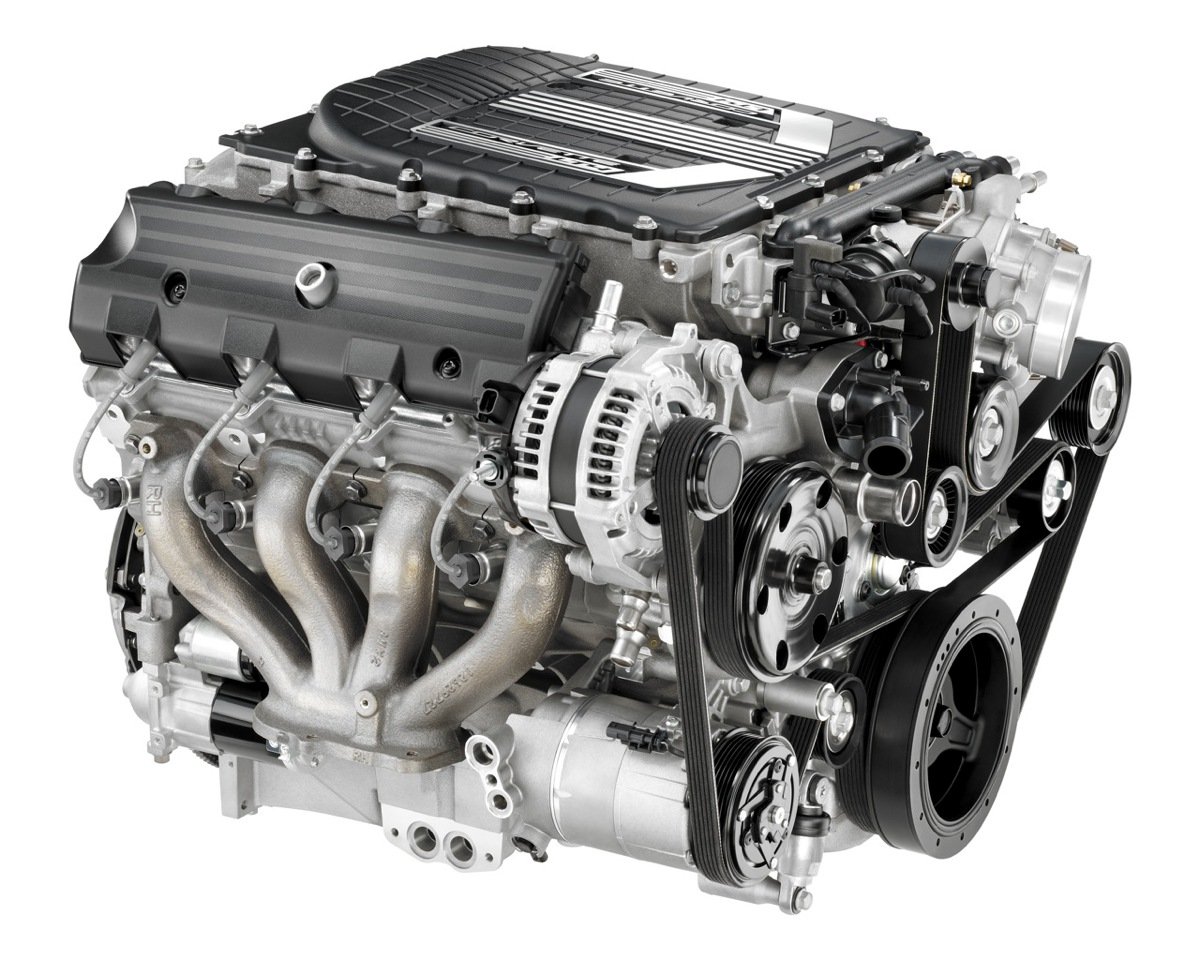

The all-new 2015 Corvette Z06 (left) and 2014 Corvette C7.R race car (right) were co-developed, and represent the closest link in modern times between Corvettes built for racing and the road. Below are two views under the hood of the consumer version.

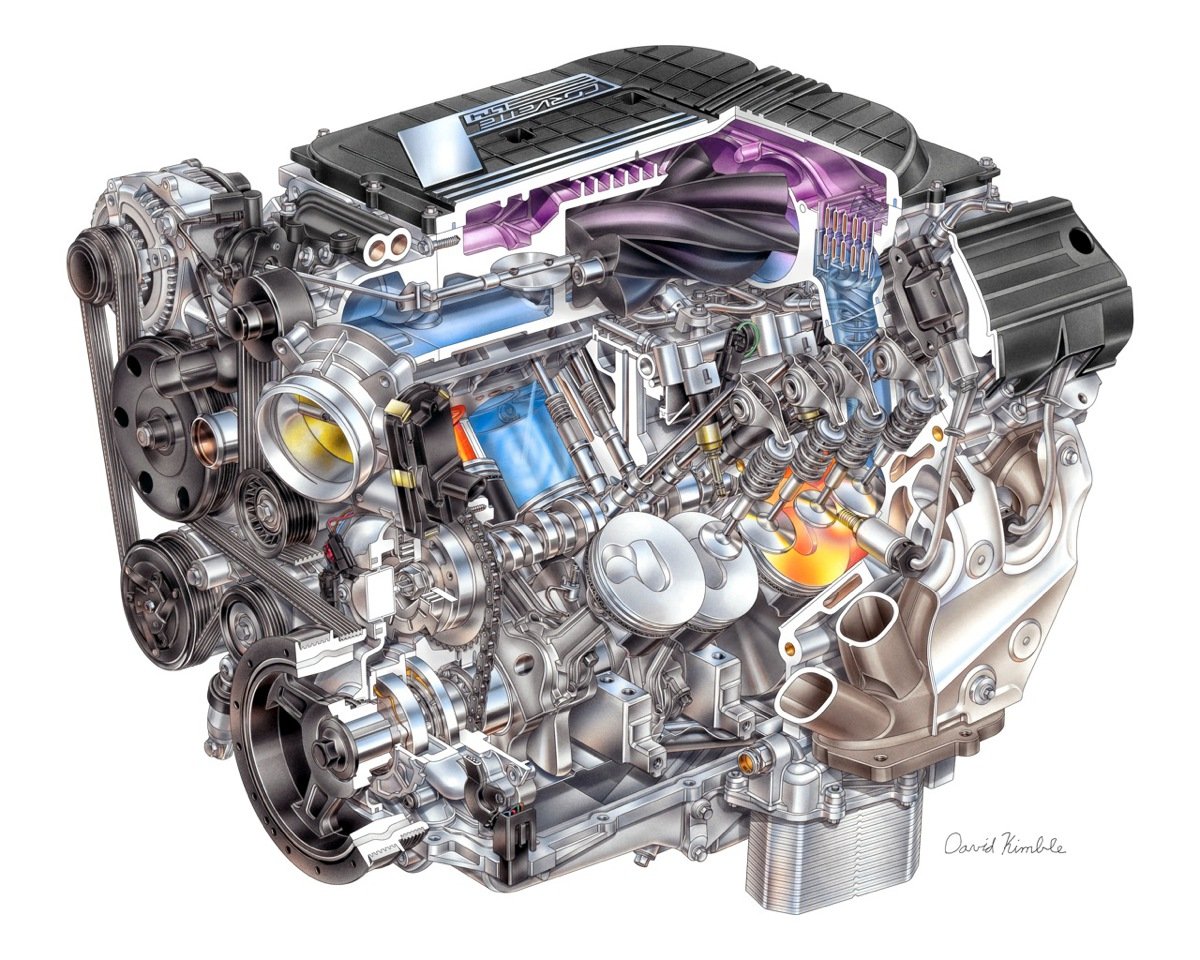

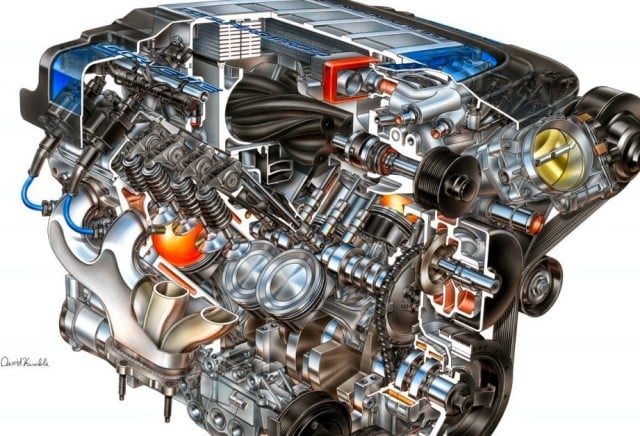

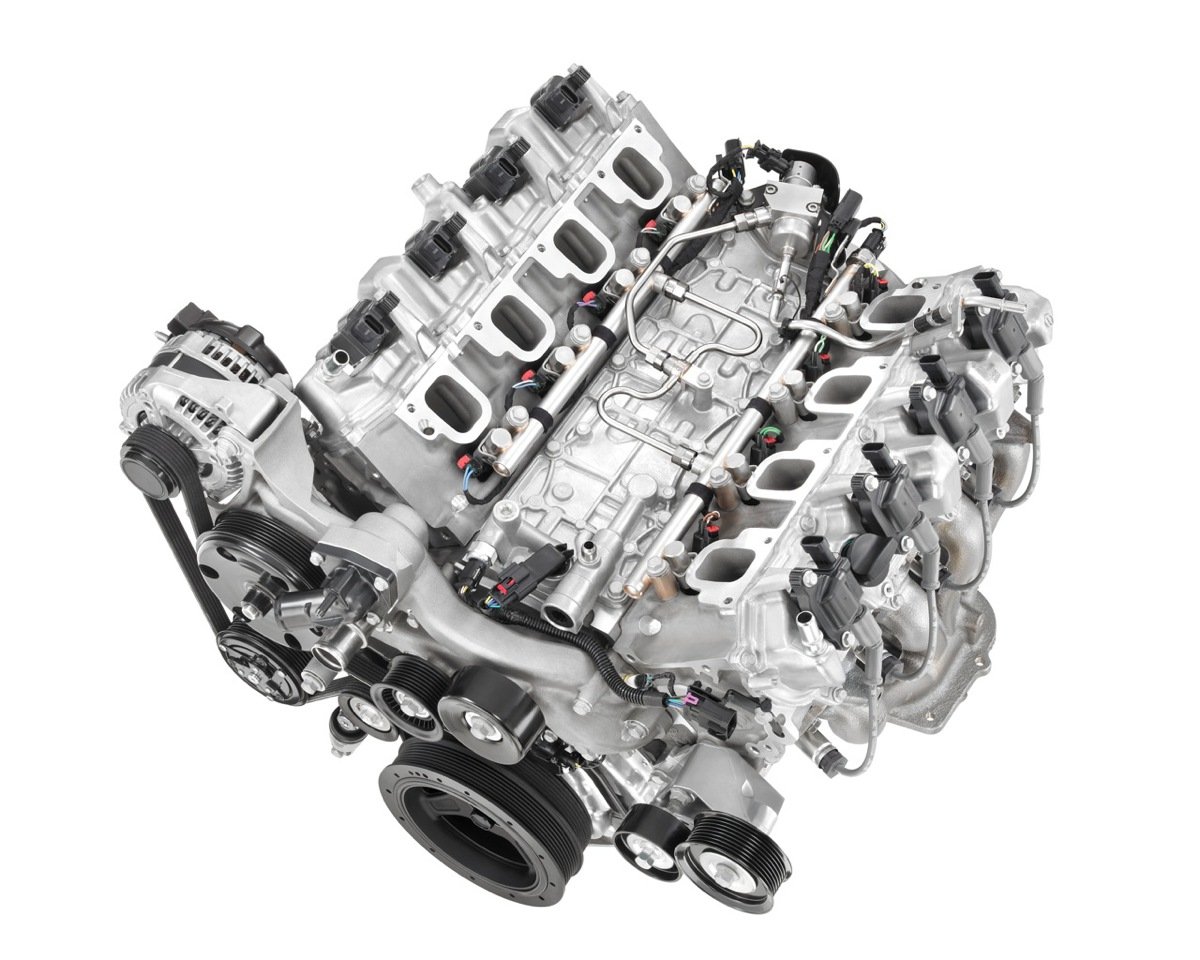

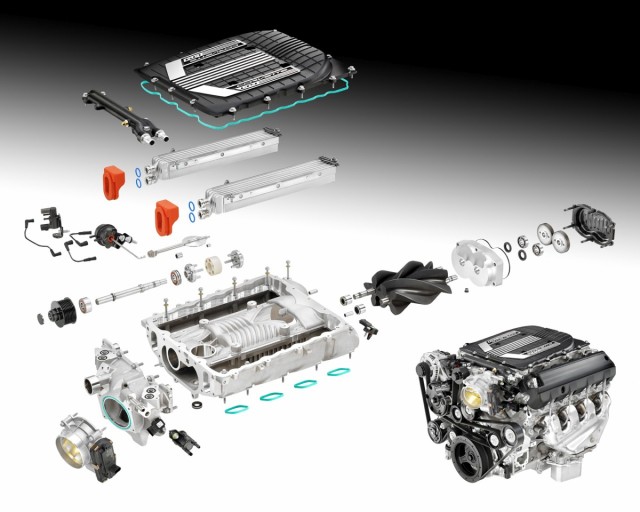

Beauty and cutaway views of the LT4 engine.

Opening up the hood

Knowing those types of motivating factors, it’s understandable if opening the Z06 hood doesn’t exactly cause your jaw to drop. There’s the predicable engine cover and maze of wires and plumbing that come with modern powerplants. But EngineLabs looked deep inside this engine and discovered a wealth of innovation and advanced features that goes beyond the fifth-generation LT1 small-block previously analyzed on these pages.

There was considerable CFD development on the air as it exits the rotors and turns over to the plenum area.–John Rydzewski, GM engineer

Exploded view of the Eaton supercharger. Below, three views of the supercharger, its placement on the engine and the engine cover.

Revving up the Supercharger

Looking Back at the LS9

The 6.2-liter LS9 was featured in the 2009-2013 Corvette ZR1 and rated at 638 horsepower with 604 lb-ft peak torque. The most powerful of all Gen IV small-blocks, it has the same bore and stroke as the LT4 but the compression ratio was 9.1:1.

GM also gave the LS9 the best internals, including forged-steel crank and titanium connecting rods. The heads sported L92-style ports and included titanium intake valves. The hydraulic roller cam spec’d out at 211/230 duration at 0.050 with .562/.558 lift. The LS9 is currently offered a GM crate engine, PN 19244099.

Veteran Corvette observers will invariably draw comparisons of the LT4 to the supercharged Gen IV LS9 that powered the Corvette ZR1 from a few years ago. The new Eaton supercharger features rotors that are shorter (7.9 inches compared to 8.3 inches) and smaller in diameter (3.9 inches vs. 4.4 inches).

The LT4 blower is driven 3.10 times crank speed, compared to 2.32:1 for the LS9, allowing it to spin up to 20,150 rpm – 5,000 rpm more than the R2300 TVS supercharger in the LS9. According to GM, the LT4 maxes out at 9.4 pounds of boost, compared to 9.7 pounds for the LS9.

“There are speed limitation guidelines on the supercharger for bearing durability,” notes John Rydzewski, assistant chief engineer for the small-block program at GM Powertrain.

To control the intense airflow dynamics produced by such a compact, high-revving supercharger, GM engineers had to design a discharge port that creates less turbulence, reduces heat and properly distributes air to the cylinders.

Getting the air straight

“There was considerable CFD development on the air as it exits the rotors and turns over to the plenum area,” says Rydzewski, adding that additional work was needed to ensure the supercharger’s tight tolerances were maintained during the blower’s life cycle. “The key is FEA analysis and very good structure in the housing so that the bore geometry does not distort.”

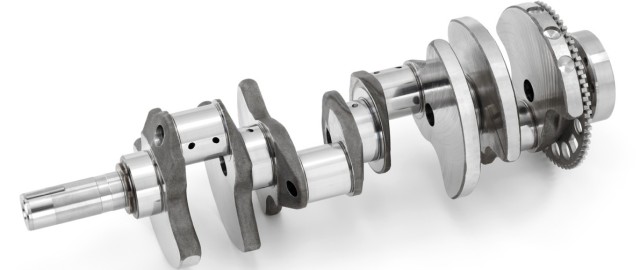

A stronger forged-steel crankshaft was needed to support the higher cylinder pressures. Below, note the difference in the LT4 piston, left, and the LT1 piston designs.

According to the dyno chart, the LT4 produces 457 lb-ft of torque just off idle and 625 lb-ft by 2,800 rpm. By comparison, according to GM’s numbers, a V12 engine from a Ferrari Berlinetta offers 28 percent less torque even though it produces 12 percent more top horsepower. All totaled, the LT4 maintains 90 percent of peak torque (592 lb-ft) from 2,500 to 5,400 rpm.

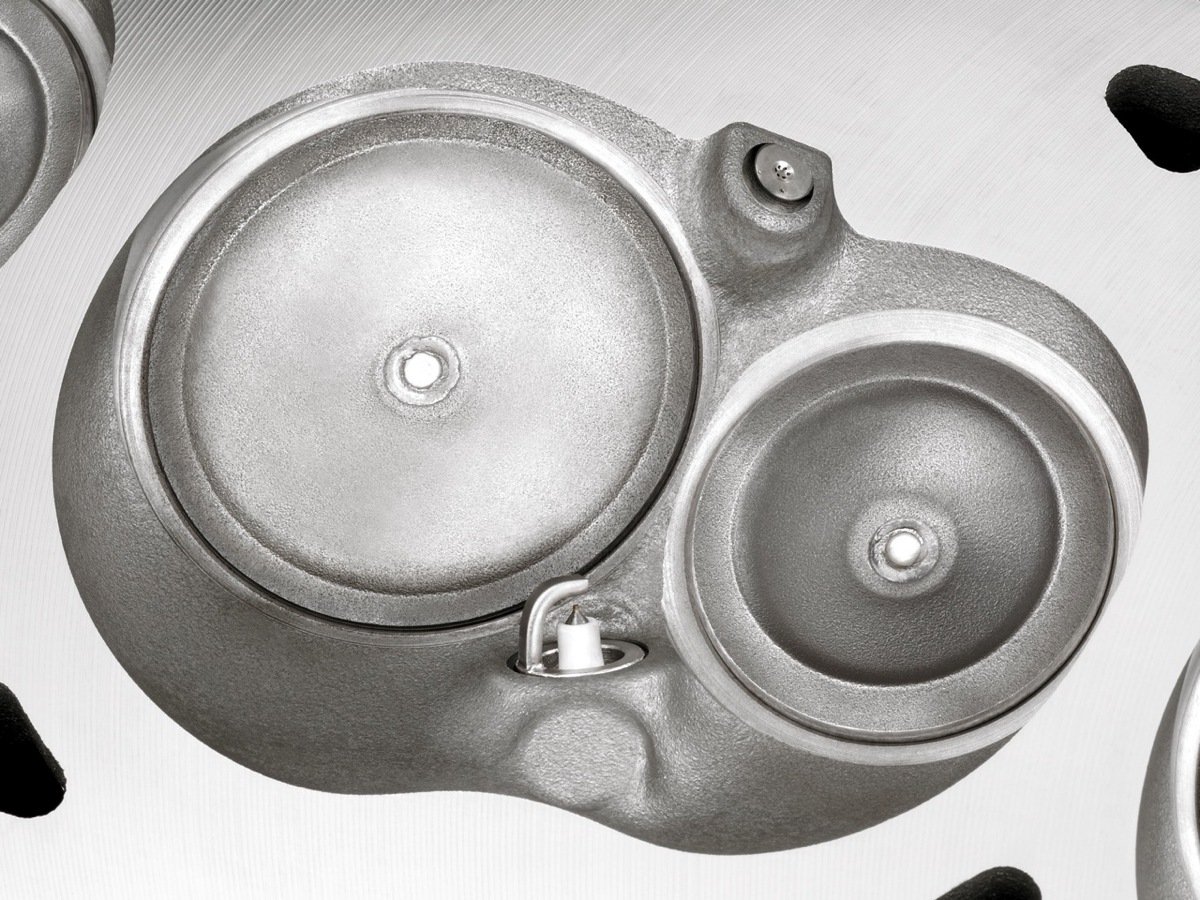

The LT4 combustion chambers (left) had to be enlarged to help lower the compression ratio over the LT1, shown on the right.

Beefing up the hardware

The higher cylinder pressures produced by the supercharger required upgrades in the rotating assembly. These changes included a 1528MV forged-steel crankshaft with tungsten balancing inserts, high-strength powder-metal connecting rods and a lightweight aluminum damper. Since the compression ratio was lowered to 10:1, a new piston design was required. GM came up with a forged alloy that features a flat-top crown, then beefed it up with internal ribs similar to the LS9 piston and included a DLC wrist pin. Ring selections were also addressed, stepping up a PVD-coated top, chrome-coated second and nitride oil control.

“Again, all concerns [for durability] were identified during FEA,” says Rydzewski. “Sensitivity was confirmed during testing.”

“Again, all concerns [for durability] were identified during FEA,” says Rydzewski. “Sensitivity was confirmed during testing.”

The cylinder head has the same basic design as the LT1 but is constructed using Rotocast A356-T6 aluminum for more durability and heat transfer. Rotocasting means the mold is rotated during casting to reduce porosity. Also helping lower the compression ratio is a larger 64.7cc combustion chamber, compared to the LT1’s 59.02cc. The heads are fitted with 54mm titanium intake valves and 40.4mm sodium-filled exhaust valves.

GM played with the cam profile by increasing the exhaust duration to handle the extra charge in the cylinder, and also decreased the intake duration. The new cam specs are 189/223 @ 0.050, compared to the LT1’s 200/207 @ 0.050. Total lift is .492/.551.

The direct-injection system was upgraded with higher-flowing injectors, larger fuel pump and fuel rails that can support nearly 3,000 psi.

“We also widened the lobe separation,” adds Rydzewski. “The LT4 has 120 degrees while the LT1 had 116.5 degrees.”

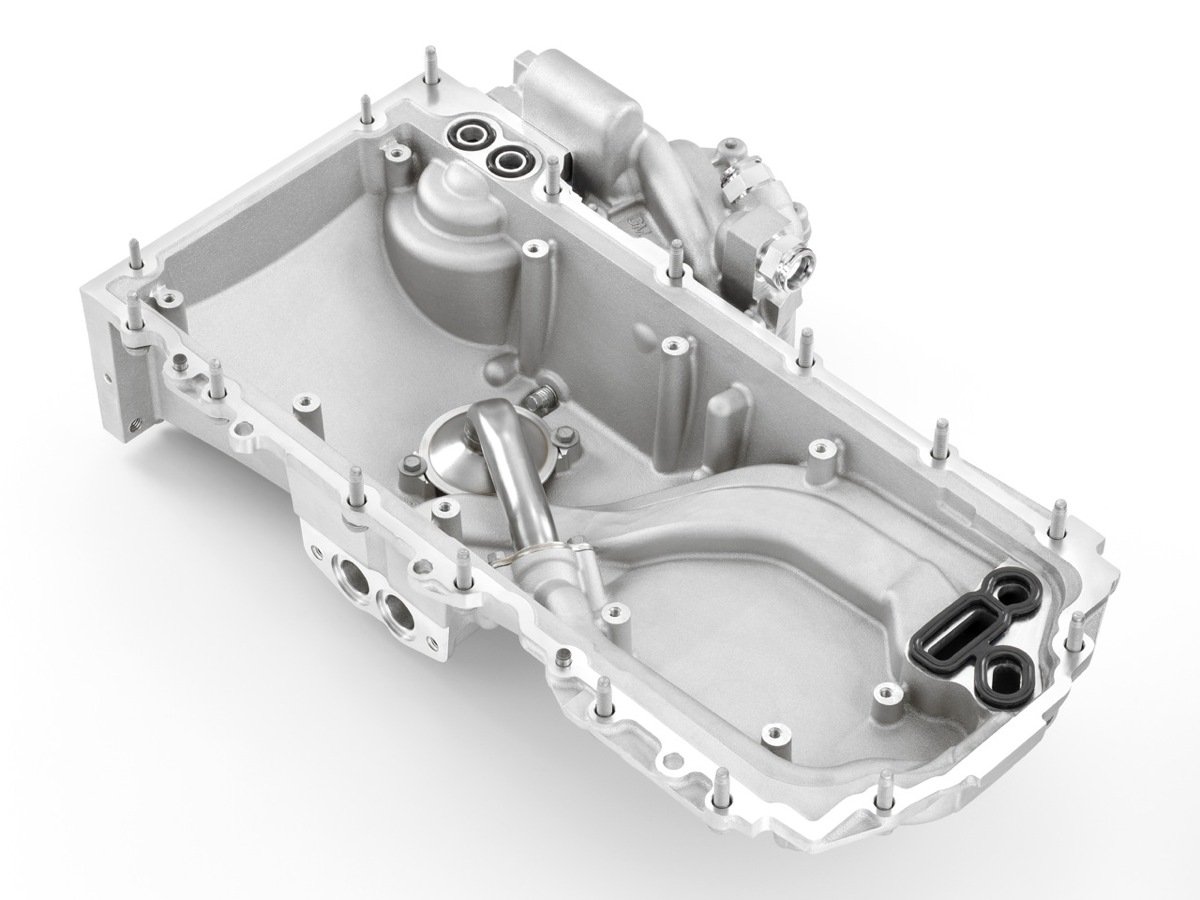

Dry-sump lubrication standard

Obviously more fuel is needed to keep up with the increased air charge. A new fuel pump rated at 2,900 psi was developed (the LT1 is rated at 2,175 psi). GM also added higher-flow injectors (25cc/second vs. 20cc) and changed the spray cone. A new fuel rail was also needed to support the increased flow and pressure.

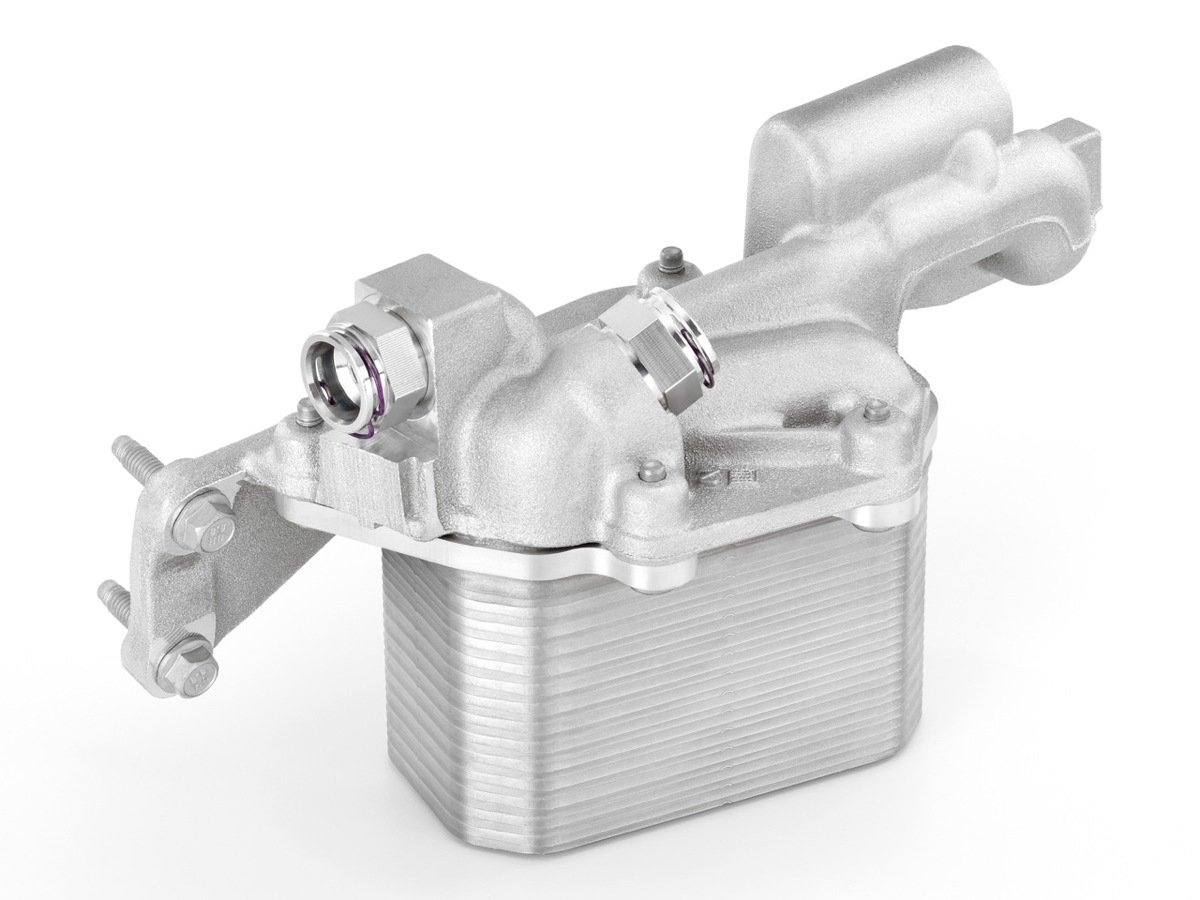

The lubrication system features, from left, a dry-sump pan, individual piston oilers and an oil cooler.

Dry-sump oiling is standard. The LT4 features a variable-displacement pump and dual-pressure control to deliver flow as demanded and ensure enough pressure at low rpm to support the cylinder deactivation system as well as high pressure during high rpm bursts. The crankshaft-driven oil pump also uses high-strength scavenge pump gears to feed fluid to the 10.5-quart oil tank and through a larger capacity oil cooler. As added safeguard, the LT4 has oil-spray piston cooling.

The engine’s low profile allowed Z06 designers to meet pedestrian protection requirements, especially tough in global markets where the Corvette will compete against other supercars.

As with any supercharged engine, noise and vibration issues had to be addressed.

“There are ribs and acoustic treatment in the supercharger lid for NVH,” adds Rydzewski.

The LT4 will be assembled at the new Performance Build Center at GM’s Bowling Green assembly plant in Kentucky as well as the Tonawanda engine plant in New York. The 2015 Corvette Z06 hits the dealer showrooms in the fourth quarter of 2014.