Do a quick Google search, and you’ll likely not find the instance when thermal-barrier coatings were were first used. Regardless, the aerospace industry and the military were more than likely there in the beginning. And like many technologies, they’ve trickled down to the civilian world, with the automotive performance market eventually employing these advances to improve combustion efficiency. Most automotive enthusiasts probably do not care who developed these coatings or when they were invented, only that it has benefited many engines since then. But, are these modern miracles of science of any substantial value or benefit to the casual hot-rodder?

All of the pistons we use will have a dry film lubricant on the skirts. – Trevor Doelling

To get the skinny, we contacted Trevor Doelling of Texas Speed and Performance in Georgetown, Texas, and Kevin Willis of Automotive Performance Engines in Auburndale, Florida. Texas Speed specializes in the late-model LSX and LT1 engine platforms, and APE has been building engines for street, Stock, and Super Stock drag racing for years. Together, we’re confident these gentlemen are more than qualified to give their professional opinion about the use of engine coatings.

Unless you have been hidden under a rock for the past decade or so, we’re certain you at least have a basic knowledge of what engine coatings are, but, as a quick refresher, the objective of engine coatings is to hinder the transfer of heat, reduce friction, shed oil, or inhibit corrosion. When discussing engine coatings, each one falls into one of five categories: antifriction lubricants (lubricity coatings), thermal-barrier coatings, thermal dispersants, oil shedders, and corrosion and chemical-resistant coatings. Keep in mind, some coatings might even fall into more than one category. For example, you could have a corrosion inhibitor that also disperses heat.

Keeping It Slippery

Lubricity coatings (antifriction) like those used on piston skirts and engine bearings, typically come as a dry-film lubricant. They are designed to reduce friction, galling, and seizing. In some instances, these coatings can also help disperse heat, which is an added benefit. These coatings typically contain molybdenum disulfide or tungsten disulfide, and the application method and binder technology are critical in getting the coating to stick to the surface in long-term use.

“All of the pistons we use will have a dry film lubricant on the skirts. The process does vary depending on the piston manufacturer, but the theory is the same. The skirt coating helps to reduce friction and noise in the cylinder,” Trevor says.

“This is something that is now standard on all Wiseco, Mahle, and Diamond pistons that we use in our builds. The coating reduces friction as well as helps to quiet the piston in the cylinder bore. This not only helps in reducing parasitic loss, but also enables quieter operation.”

Piston skirt coatings can help reduce the amount of scuffing that can occur on the piston and cylinder wall.

When an engine is experiencing heavy load conditions, moly-based dry-film lubricants actually have the ability to hold oil on their surface, which enhances the integrity of the oil film between the metal parts. When used on bearing surfaces, these coatings can help ward against metal-to-metal contact if oil pressure is lost. There have been claims made that small power gains can be made with their usage on bearings, but since an engine’s journals and bearing surfaces are already separated by the oil and (hopefully) never come into contact, it’s hard to see how bearing coatings would add any power under standard operating conditions. Therefore, the main advantage is really its use as an insurance policy of sorts, enhancing longevity, and providing emergency protection if something does go wrong.

Oil Shedders

Usually based on PTFE (Teflon) or similar fluoropolymers, oil shedders–as their name implies–help the coated part shed oil to improve oil return to the pan. Many know a version of this called Glyptol, and it is often used to paint the lifter valley and area under the valve cover to help with oil drainback. These coatings are also sometimes applied to the undersides of pistons, connecting rods, crankshaft counterweights, windage trays, and even the inside of oil pans, timing covers, and valve covers. Basically, any place within the engine where you do not want oil to collect is a candidate for an oil shed coating.

Shedders may improve overall high-rpm engine lubrication while reducing oil temperature, and can also help reduce varnish, sludge buildup, and corrosion. Some even claim that shedding oil may cut drag on rotating parts, providing power benefits. But such gains would surely only benefit those searching for every ounce of power they can extract from an engine.

“We have used it before and I think it’s a good idea, but it does take a lot of block preparation before it can be applied. If the block is properly prepared, the coating can definitely help get oil draining back to the oil pan. But, if the surface being coated is not clean – and I mean really clean, it can flake off,” Kevin says.

Thermal Barriers

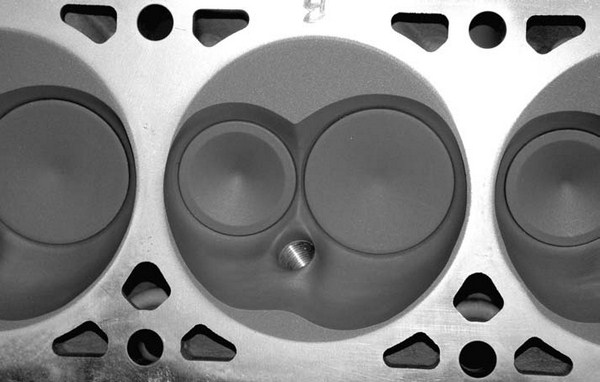

It is no secret that heat management is essential for engine longevity and efficient power output. Many times, ceramic-based thermal-barrier coatings are used to reduce heat by reflecting that heat away from the coated part, like a piston top or cylinder head chamber. When applied to a piston’s top, a thermal barrier reflects the heat from combustion into the combustion chamber. This reflected heat translates into more energy to push the piston down the bore. Also, coating the piston’s top actually creates a smoother surface, which minimizes hot spots on the piston’s surface. This can decrease the potential for detonation.

Chamber coatings can reduce overall cylinder head temperature by reflecting the heat of combustion away from the cylinder head.

Applying a thermal barrier in the combustion chamber can also help with increasing power potential by increasing combustion efficiency while lowering engine coolant temperatures.

“We rarely use combustion chamber coatings since only the most extreme applications require this. The chamber coatings can both help improve combustion temperatures while also reducing overall cylinder head temperature,” says Trevor.

You will also see these used in the extreme supercharged and turbocharged applications where heat is a big concern.

“When it comes to piston tops, I think it’s a good idea. I also think that if you are going to do it, you should also coat the combustion chambers to realize the full benefit of it. But, the budget plays a large part in the decision. While I think there is a gain there, I also feel that the average enthusiast can better spend his cash elsewhere for greater performance gains,” says Kevin.

Coated Bearings

Most of the time, coated bearings are not a priority. – Kevin Willis, APE

“I don’t use them all the time,” Kevin says. “In mildly-built restoration or a street-duty engine, no, we don’t use them. Every guy or girl that walks through my door has a budget, and I try to deliver everything he or she wants within their budget. Most of the time, coated bearings are not a priority.”

Coated bearings are a good insuracne policy to help combat bearing wear, especially if oil starvation occurs.

The mindset about using a coated bearing relates to insurance against catastrophic failure if you lose oil pressure. When an engine is running, the oil keeps the metal parts from contacting the bearing surface. The coating comes into use when the oil, for whatever reason, is removed from the scenario. The coating will–to an extent–protect the metal surface for a short time.

“Bearing coatings will sometimes be used at the customer’s request. We typically use the Clevite and Calico-coated bearings, which use a dry-film lubricant to reduce friction and abrasive wear,” says Trevor.

“This would be beneficial in the higher heat applications previously mentioned, as well as high-RPM applications (7,500+). These coatings also help to provide a buffer during a brief period of oil starvation, such as during cold start up. With that said, they are not a requirement for the majority of engines that we build where their intended use is on the street making 600 and 700 flywheel horsepower.”

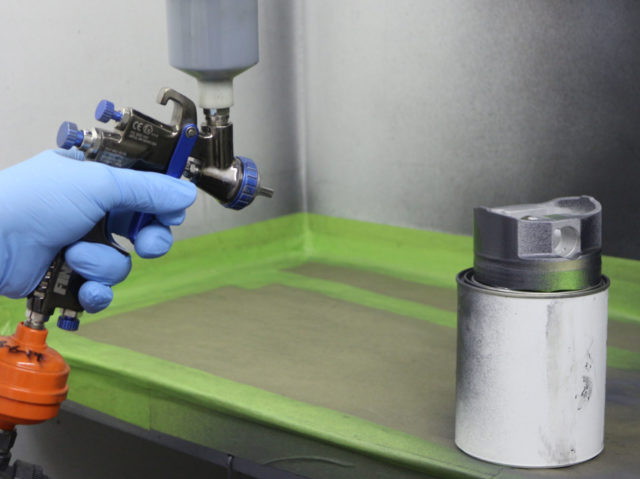

At-Home Coatings

There are some manufacturers that even sell do-it-yourself versions of their coatings that are designed to be applied by the average home enthusiast. It goes without saying that the durability of the retail version might not be the same as a professional version. Also, the at-home user might not be able to have the same installation conditions like a controlled environment to ensure proper adhesion. Achieving a consistent, critical thickness of the coating, and a proper baking temeperature and cycle are challenges that the home user need to ensure. That is because they are critical to the coating’s effectiveness and longevity.

Header Hype

When it comes to header coatings, ceramic materials are more than just a nice wrapper. Sure, they will inhibit corrosion much better than a covering of rattle-can rehab will, but to take advantage of the anti-corrosion benefits of header coatings requires the inside of the headers also be coated. Combustion gases will create moisture inside the header, and if not coated, that condensation can eventually cause the header to rust from the inside out.

Most of the time, the reason for purchasing a set of coated headers is their appearance. Their good looks last infinitely much longer than paint that burns off almost immediately. But remember, if the header is not coated on the inside, those shiny looks could have a limited lifespan.

So, whether or not any of these engine coatings is a viable option for your engine is a decision only you can make. Many times, the money utilized toward the added expense of a coated part could possible yield a better benefit if used in another aspect of your build. The choice is yours, and is something you should discuss with your engine builder to get their recommendations for your particular project.