Can you remember the last time an American independent shop attempted to design and develop an engine capable of winning the Indy 500?

Can you remember the last time an American independent shop attempted to design and develop an engine capable of winning the Indy 500?

When the IRL first organized in the mid-‘90s and decreed that all approved engine components be available to engine builders outside the factories — much like NASCAR’s game plan today — such diverse shops as Brayton, Comptech Machine, Katech, Roush, VDS, Menard and Speedway Engine Development scored open-wheel victories with the Oldsmobile Aurora V8. And legendary builder Ed Pink worked with the Nissan engines that fell under the early IRL rules. Of course, the IRL folded like a wet noodle a couple years later when Toyota and Honda whined that they would only lease complete engines — not develop parts for sale — and IndyCar racing became nothing more than another crate-engine program.

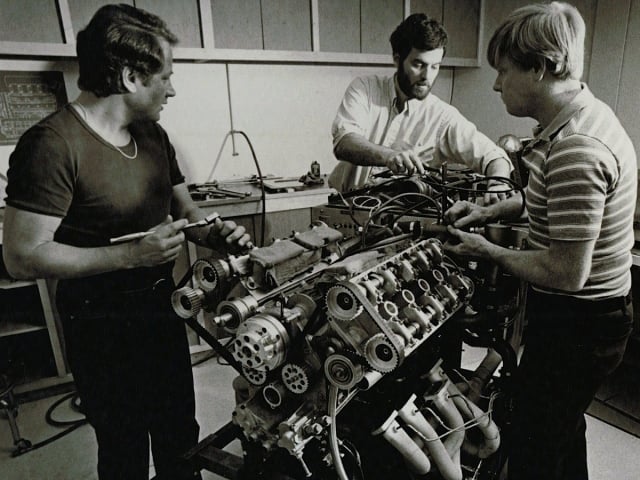

From left, Hans Hermann, Reeves Callaway and machinist Fuerher confer over one of the early HH V8 prototypes.

But all those original IRL engine maestros started with a platform developed by an automaker with considerable technical resources and manpower. They already had the block, heads and numerous other critical components for a starting point. What about an Indy 500 race-specific, clean-sheet engine design generated solely from small shop based in the U.S? And also, have that engine cast, machined, assembled and running on the dyno in 11 months?

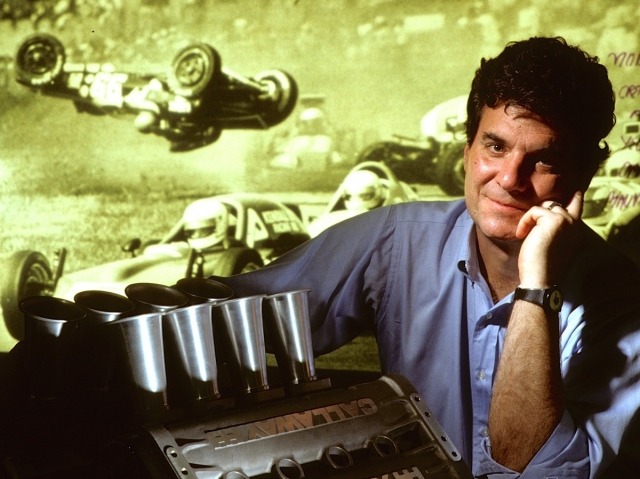

The answer is found in Connecticut where Callaway Cars is based.

Teaming with experienced engine developer Hans Hermann in the early ‘80s, Reeves Callaway set out to build a 2.6-liter turbocharged V8 that would challenge the Ford-Cosworth DFX — a derivative of the Cosworth DFV Formula 1 engine — that was dominating the American Champ Car racing scene.

“As an engineering company, we were really interested in showing our capabilities,” remembers Callaway, who eventually developed the celebrated Callaway twin-turbo Corvettes and other limited edition vehicles such as a twin-turbo Alfa Romeo. Callaway now produces upscale supercharged versions of the Corvette, Camaro and GM full-size pickup. “We thought there was an opportunity to make a serious Indy engine to the current specs.”

Recognizing Hans Hermann’s expertise

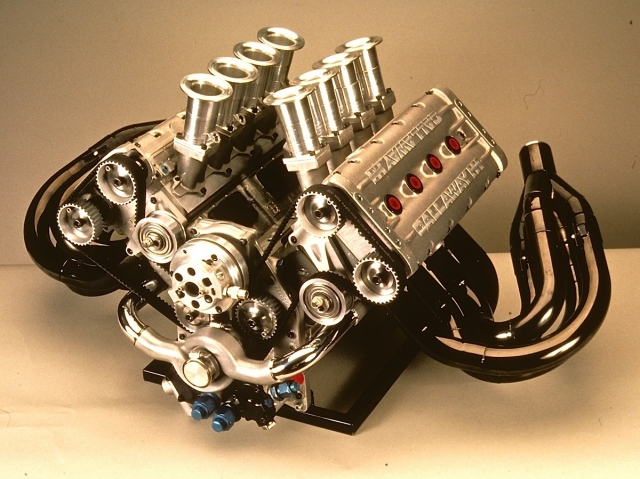

Designated as the HH V8 in recognition of Hans Hermann’s contributions, prototypes of the Callaway engine were making power consistent with the competition when the initial funding dried up.

“The problem with 1984 was that the economy was tanking with both the fuel crisis and the interest rates,” Callaway tells EngineLabs. “It became more difficult to raise money, which ultimately fuels engine development.”

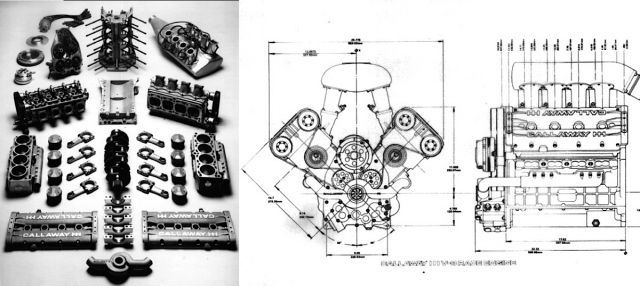

Left: An exploded view of the HH V8 shows all the components developed by Callaway. Right: The drawing illustrates just how clutter-free the lower sides of the engine are with the oil and scavenge pumps enclosed up front. Advancements in cog belts allowed Callaway to design the primary drive for the pumps, accessories and timing pulleys with gears but stretch belts to drive the camshafts. Also note the coolant design with water delivered directly and equally to the cylinders.

Callaway’s adventure certainly revives memories of an era when engine innovation was as much a cornerstone of the Indy 500 lore as the Marmon Wasp mirror or even the Snake Pit. Remember the battle between the purpose-build Miller straight-8 and the supercharged Duesenbergs in the very early days? Then came the “Junk Formula” in the ‘30s that brought Buick, Maserati, Studebaker, Stutz, Auburn and other automakers into the Brickyard. When Offy was the engine to beat — winning 18 straight Indy races — Ferrari, and even Cummins, challenged the iconic 4-banger, along such notable racing legends as Mickey Thompson and Smokey Yunick.

The high-water marks of this engine are the great combustion chamber and the flat valve angles.–Reeves Callaway

Then came Ford’s domination with its own 4-cam engine as well its partnership with the Cosworth DFX. Oh yeah, there was slight diversion of attention when Andy Granatelli brought the silent whoosh of Pratt & Whitney turbines to the track. Also, humoring Gasoline Alley about that time was the bold turbo V8 from AMC Motors that reportedly made more than 1,100 horsepower. It was stupid fast on the straightaway but so heavy and clumsy in the turns that it was a menace to the field.

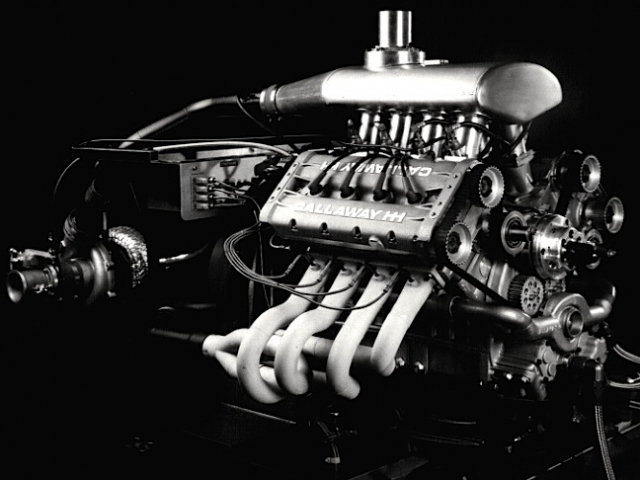

Another view of the HH V8 during testing. Note the pop-off valve required to limit boost to 50 inches of manifold pressure, or about 9 pounds of boost.

The DFX seemed to be so invincible that even Porsche failed at fielding an engine in the early ‘80s. USAC rules favoring stock-block engines tried to encourage new participation. Chevy had noted engine developer Ryan Falconer work on its V6, and Buick was also playing with its V6 powerplant. With the added allowable displacement and turbo boost, the stock-block engines made significant power but suffered constant durability problems. The winners of that day were simply relying on English-built Ford-Cosworth engines.

“I was sure there would be a market for an American Indy engine,” says Callaway. “This engine was designed to be a calling card. Indianapolis was ripe for a new engine design because manifold pressures were coming way down (Cosworth was cut from 80 inches to 50 inches in 1979). The HH V8 has some really sensational design features.”

Leveraging experience from the Offy legacy

Hermann was on the tail end of the Miller-Offy-Meyer-Drake dynasty that produced so many winning engines. Hermann had suggested building a clean-sheet V8 engine for the Speedway to John Drake in the late ‘70s. The DT-160 was designed to be versatile enough that the cylinder head could be used on a V8 or I4 block, but that option prompted the team to use rubber timing belts for the camshafts, not gears. The engine suffered numerous problems, then the budget ran out. Also, Drake was constantly busy working to keep the dwindling number of Offys running on the track and couldn’t devote enough time to the V8.

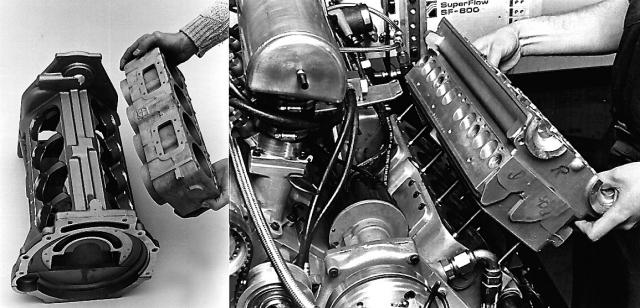

Left: See how each cylinder bank can be removed from the crankcase. The parts are obviously unmachined, but the demonstration clearly shows the versatility of the design. Right: Long studs secure both the cylinder bank and the cylinder head. Note the distributor in the center valley and an early twin-plenum intake manifold design.

“Hans was another one of those guys who could do everything himself. One man, one thought kind of proposition,” says Callaway, who tempted Hermann by showing off a shop full of state-of-the-art machine equipment. Callaway then raised an initial round of private funding to launch the project. Eleven months later when the first prototypes were on the dyno, Callaway had to swap his overalls for a coat and tie to start promoting the engine.

“That’s when you need to turn on the big faucet for money,” he sighs. “So my task shifted from being the guy in the shop making the pieces, because that’s what I really enjoyed, to going out and speaking on behalf of the project and raising more money.”

By 1984, the economy was struggling with a 12-percent prime rate and oil prices that had doubled following the Iranian revolution a few years earlier. One possible source of engine development money was Roger Penske, but he opted to fund Ilmor’s new V8 engine for Chevrolet.

“We had raised just shy of $2.5 million to get to the first stage,” remembers Callaway, noting that in today’s dollars it would take $60 million to $90 million to “legitimately do a project like that.”

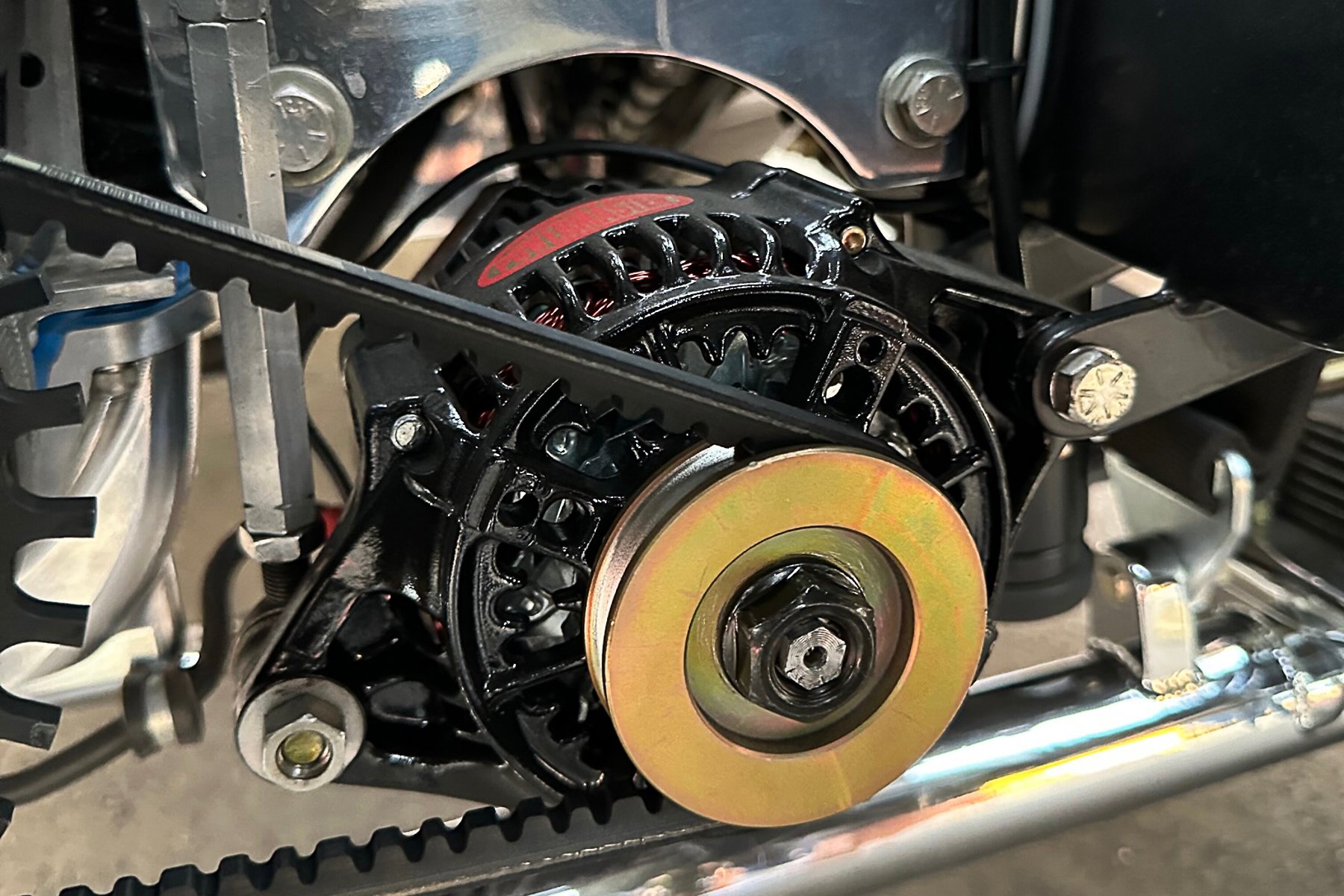

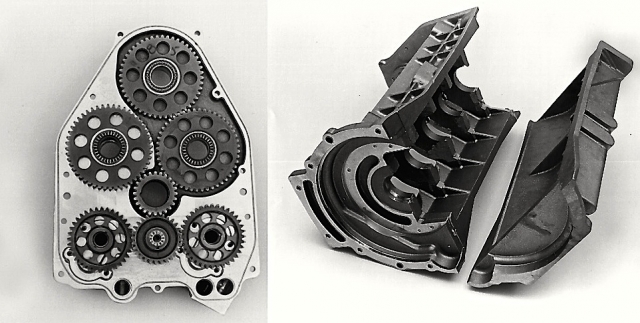

Left: Here’s a view of the primary gear drive that operated the lower oil pumps as well as the fuel pump, alternator and distributor. Note the extensive use of needle bearings. Right: Demonstration of unmachined crankcase and sump designs. The engine was designed with an existing Cosworth bellhousing bolt pattern to facilitate teams switching over.

Packaging was one of the key design elements that could have made the HH V8 a serious contender. Aerodynamics on open-wheel cars were increasingly more important to improving speed and handling, and the tunnels between the rear wheels and engine needed to be as wide as possible to not only improve downforce but also cool the engine’s heat exchangers.

“We moved all the pumps away from the sides of the engine to the front,” explains Callaway, adding that the reduced width of the crankcase would have allowed a much wider sidepod on the cars. “There was about a 25 percent increase in the area available to the tunnels.”

Innovations of the HH V8

Callaway’s design was also lighter by some 30 kilograms (66 pounds), and each bank of the Nikasil-coated cylinders could be removed from the crankcase. This capability not only aided repairs but also gave Callaway the option of producing engines with different displacements that could be designed into the crankcase footprint. With a 90mm bore on the Indy engine, there was room for water jackets between the cylinders to improve cooling over siamesed-bore engines. The cylinder head design was a pure reflection of Hermann’s experience with the Drake engines.

“The high-water marks of this engine are the great combustion chamber and the flat valve angles — around 11 degrees,” says Callaway. “And it was beautiful intake port.”

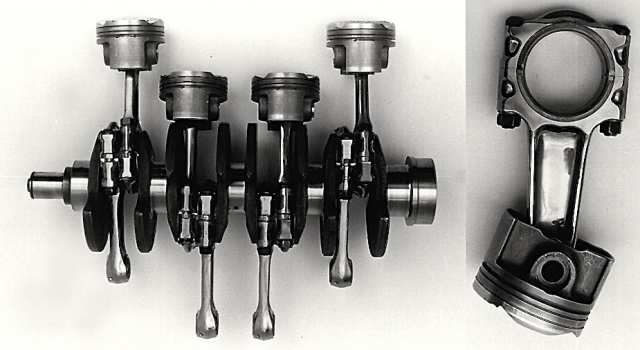

Shown is the rotating assembly with a billet Moldex crank, titanium connecting rods and Mahle pistons with a narrow skirt design. Callaway says titanium rods were risk at the time due to limited life and were deemed useable after a certain number of hours.

The engine sported dual overhead camshafts that were belt-driven, but by this time rubber belts had improved enough that maintaining cam timing wasn’t as problematic as the Drake V8. Hermann also designed the camshaft and titanium bucket followers that were chrome plated.

“Nobody had done chrome-plated titanium back then. It was a hard thing to do,” says Callaway.

Mahle developed the pistons with 1.5mm rings, quite thin for the day. They were secured to titanium connecting rods and rotated with a billet Moldex flat-plane crankshaft.

Formal photo of a naturally aspirated version of the HH V8 that possibly could have been used in sports car racing.

Hilborn supplied the mechanical constant-flow fuel injection system, and Callaway remembers getting additional fuel help from Kinsler. An experimental IHI turbo provided boost to the custom fabricated intake manifold that first had two plenums, but later evolved into a larger single plenum design. Callaway developed all of the tooling with highly regarded Ed Weimer handling the patterns. California-based A-RPM poured all the castings.

Networking pays off

“Hans knew all of these guys personally and was able to bring their talent to the table,” says Callaway. “We leveraged all sorts of American racing with the project.”

The remainder of major components were machined in house as the first engines came together.

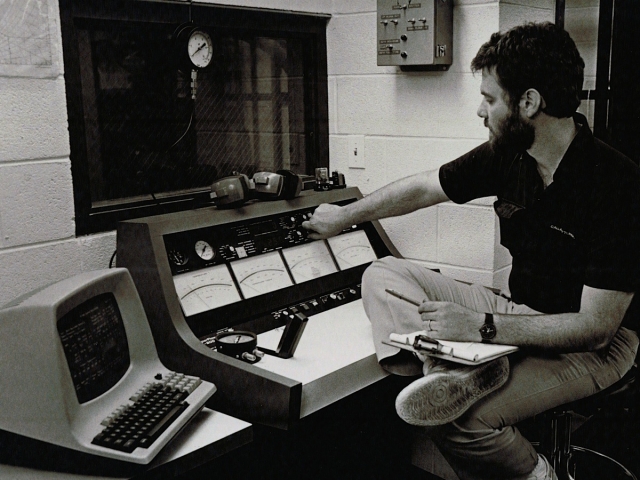

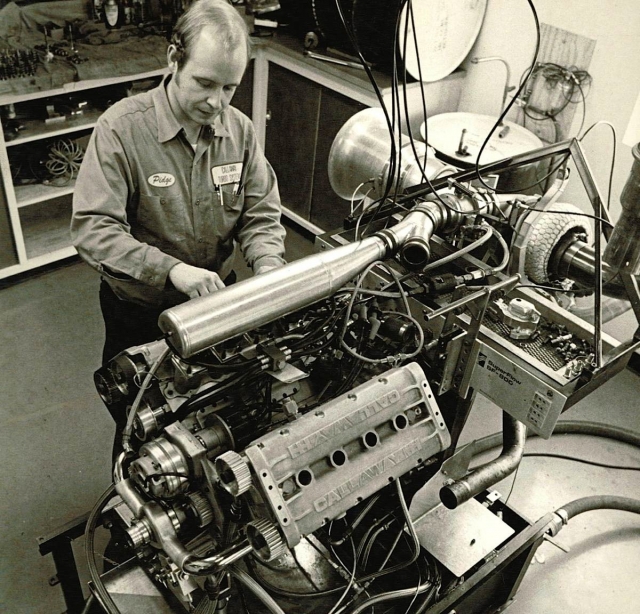

Pidge Gills sets up an engine for more tests. Note the early dual-plenum inlet design and the alternator mounted in front of the distributor.

“The goal on the dyno was 715 horsepower. The first time we fired up the engine, we were around 680,” remembers Callaway, noting that allowable boost was around 48 inches of total manifold pressure, or about 9 psi. “We never tested a Cosworth, but I don’t think we exceeded what we had heard a good Cosworth was making. That would have been part of the next step, but we were certainly within striking distance.”

Sorting out reliability issues, checking the coolant flow and experimenting with ignition timing and fuel control were priorities on the dyno.

“It was our first ever running on alcohol,” laughs Callaway. “Those systems were a little crude with constant flow.”

Just as the Indy engine money started drying up, Callaway was contracted to develop a twin-turbo system for the Corvette, and then a twin-turbo job came in from Alfa. He was also approached to build road-racing engines for Aston-Martin.

“We got very busy at that point,” says Callaway. “The company was moving ahead with much more commercial necessities than building a race engine.”

All of the tooling and parts developed for that project are still in storage at Callaway’s shop. Unfortunately all that work and ingenuity is relegated to fond memories today.

“But I was always pleased,” sums up Callaway, “because of how much progress we made on relatively few dollars and how well the engine worked.”