[1]The Gen V small-block ushers in a new age of performance for Chevrolet and General Motors. The company doubled-down on the cam-in-block engine design, proving that double overhead cams are not the only way to achieve a world-class balance of power, refinement and efficiency. In fact, as Chevrolet has rightly pointed out, the 2014 Corvette Stingray – powered by the new, 6.2-liter LT1 version of the Gen V – is rated at 455 horsepower and 29 miles per gallon on the highway, making it the most fuel-efficient sports car in the world. Direct injection, variable valve timing and cylinder deactivation technologies contribute to making the engine a gas-sipping powerhouse.

[1]The Gen V small-block ushers in a new age of performance for Chevrolet and General Motors. The company doubled-down on the cam-in-block engine design, proving that double overhead cams are not the only way to achieve a world-class balance of power, refinement and efficiency. In fact, as Chevrolet has rightly pointed out, the 2014 Corvette Stingray – powered by the new, 6.2-liter LT1 version of the Gen V – is rated at 455 horsepower and 29 miles per gallon on the highway, making it the most fuel-efficient sports car in the world. Direct injection, variable valve timing and cylinder deactivation technologies contribute to making the engine a gas-sipping powerhouse.

Along with the small-block engine, GM also doubled down on the production facility to build it – the iconic Tonawanda plant, just north of Buffalo, N.Y. Opened in March 1938 to produce the Chevy inline-six that was affectionately called the Cast Iron Wonder and, more popularly, the Stovebolt, Tonawanda has rolled with the best and worst times in the auto industry, somehow persevering in the tough times with the quality and workforce tenacity that led it to more prosperous periods.

[3]

[3]The Tonawanda engine plant located north of Buffalo, New York, has been building engines since 1938.

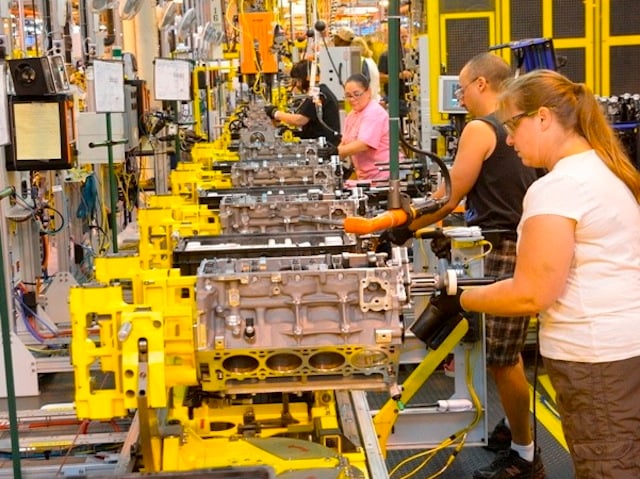

Production of the Gen V engine family, which includes a 4.3-liter V6, 5.3-liter V8 and a pair of the 6.2-liter V8 engines – the Corvette’s LT1 and a version for full-size trucks – caps a $400-million investment in new tooling, quality assurance systems and training. It has also helped add or preserve approximately 1,500 jobs in the plant, which is more than double the workforce that hung on for one shift during GM’s bankruptcy a few years ago.

The plant’s history traces back to a time when the nation’s economy was recovering from the Great Depression. Chevrolet’s sales increased tremendously, straining production capacity at all levels. The company needed a new engine production facility, among other things, and found an ideal location in the Buffalo, N.Y., area. It was relatively close to GM’s East Coast facilities and even closer to Bethlehem Steel’s Lackawanna, N.Y., plant, which would feed the new plant quickly and conveniently.

Engine Building in Buffalo

After breaking ground in 1937, the 1 million-square-foot Chevrolet Motor and Axle Plant cost $12.5 million to construct, the equivalent of nearly $200 million today, when adjusted for inflation. Virtually every component in the engines was produced or machined on site and the gear-cutting equipment, for example, was considered among the most sophisticated and precise in the industry.

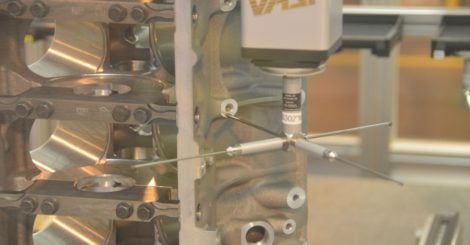

The assembly process starts with the Gen V's new block casting, which is refined from the previous “LS” design. As part of Tonawanda’s new Track and Trace systems, the blocks and cylinder heads are fitted with “data bolts” to prevent missed machining processes. The reusable bolts use radio frequency identification technology and can reliably identify the exact time and place a block or head goes through each process. Also part of the quality control process is a Zeiss coordinate measuring machine that examines more than 11,000 data points to within 2.5 microns.

The Gen V small-block engines are among the most advanced and high-tech in the world.–Steve Finch, Tonawanda plant manager

By the end of 1938, after coming on line earlier in the spring, Tonawanda produced a relatively modest 10,500 engines and 21,000 axle assemblies. The plant was just getting its production groove on when World War II came along and aircraft engine assembly supplanted the Chevy six. A 114,000 square-foot addition to the plant was constructed to support assembly and testing of enormous, 18-cylinder, 2,100-horsepower Pratt & Whitney engines for war birds, including the P-61 “Black Widow” night fighter and the Republic P-47 “Thunderbolt.” A 14-cylinder engine for B-24 Liberator bombers was also produced at Tonawanda.

[8]

[8]With all of the blocks’ machining and inspections completed, they move down the assembly line, where they’re fitted with the rotating assembly components. The crankshaft in the Gen-V small block is located with new nodular main bearing caps – a significant upgrade over more conventional grey iron main caps.

Post-war production of the Stovebolt resumed in 1946. In 1950, the 235ci version originally produced for trucks ended up in Chevy’s passenger cars and, of course, the 1953 Corvette a few years later, with the Blue Flame moniker. Tonawanda personnel were credited with helping convert the Stovebolt’s antiquated splash oiling to a modern pressure system and integrate the changes economically at the plant. It was a significant achievement that helped pave the way for Tonawanda’s nod to produce Chevrolet’s new overhead-valve V8 engine in 1955.

The Tonawanda “smart cell” assembly station consolidates the operation of four machines into one and installs 48 parts into the cylinder head in 40 seconds. An automated pallet-positioning system and two mobile robotic arms equipped with changeable tools stored on a compact tooling plate or “shoe box” perform most of the operations. One tooling arm is always working, while the other is reconfiguring for the next step in the sequence Together, three smart cells deliver a completed head in less than 22 seconds.

[12]

[12]Completed heads are show, including the data bolts that “ride” with them throughout the assembly process. Compared to the previous cylinder head design, the Gen V head features smaller combustion chambers, designed to complement the volume of the dish in the pistons to support the direct injection fuel system.

Tonawanda produced 924,000 examples of the 265ci small-block, including the estimated 693 ’55 Corvettes believed to be built with it. Along with the enduring Stovebolt and small-block, Tonawanda’s production expanded again in 1959 with the 348 “W” engine – the Mark I big-block. It would prove to be plant’s longest-running engine line, lasting until 2009.

Big-block Reputation

Indeed, Tonawanda is synonymous with the big-block. Throughout the 1960s, identifying valve cover stickers imprinted the plant’s name on the consciousness of everyone who lifted the hood of a Stingray or Chevelle SS396, but the big-block was one of six engine families produced at Tonawanda during the decade. In addition to the Chevy six, small-block and big-block, there was also Chevy’s 153ci straight four, as well as the Corvair’s flat-6 engines.

As the assembly progresses, the cylinder heads are fastened simultaneously by a computer-controlled machine, ensuring even pressure across both cylinder decks. Connections for the direct injection fuel system are carefully tightened before several additional steps ensure it is leak-free.

When it came to Corvette engines in the 1960s, Tonawanda built all the different-displacement versions of the small-blocks and big-blocks, including the all-aluminum ZL1 engine – and was the exclusive production facility for Corvette big-blocks. The ZL1 engines were hand-assembled in a special clean room away from the regular production line, then broken in for an hour before being validated in the plant’s test dyno lab, according to a historical overview produced for the plant by Annette Herrman. The ZL1’s production methods were resurrected in the mid-’70s, when the clean room was used to hand-assemble the twin-cam four-cylinders used in the 1975-76 Cosworth Vega.

[15]

[15]Pneumatically sealed tools in form of clamp shells are applied on each high-pressure fuel line joint; this forms a collection chamber encapsulating the joint, isolating it from the outer atmosphere. The fuel system’s internal volume is then pressurized with helium through another set of unique tooling. Vacuum close to absolute zero is drawn in the collection chambers.

Tonawanda marked the production of its 15-millionth engine in 1968, but the 1960s alone accounted for a staggering 9,199,000 engines – most of them V8s.

After a roller-coaster ride through the industry’s most tumultuous years, GM’s post-bankruptcy turnaround brought a stunning announcement: Nearly half of $890 million pledged to North American facilities upgrades would go to revamping the Tonawanda plant to produce the Gen V small block engine.

“The Gen V Small Block is a cornerstone of GM’s powertrain strategy and its production at Tonawanda affirms the commitment to one of the highest-skilled workforces in the industry,” said plant manager Steve Finch at a recent open-house event. “We have invested 40,000 hours and $1.8 million in training the workforce to build these engines with uncompromising quality, and we’ve added some of the most flexible equipment ever used in the industry to make sure we can meet market demand.”

Mass spectrometer technology is used during the helium test to measure leak rate at the molecular level. It can measure flow of less than 1 part per billion – less than 100 times smaller than the diameter of an average human hair! With the fuel system’s integrity confirmed, final assembly of the engine includes the intake manifold/throttle body assembly and other components.

More LT1 Information

For more information on the Gen V LT1 engine, check out these stories:

- Breaking News: Chevy Gen V Small-block Reveal [19]

- Is the Gen V Engine’s Combustion System Really New? [20]

- Corvette, GM Truck V8 Engines Have Much in Common [21]

- New LT1 Engine Rated at 460 Horsepower [22]

State-of-the-art machining and quality inspection systems include, for example, a Zeiss position check machine that quickly examines up to 11,000 data points on a freshly machined component and a Hummel surface machine that checks finish textures at less than micron. That’s a mere 0.000039 inch – less than the thickness of a human hair. There’s also a new fuel system connection inspection that’s essential to ensure safety for the direct-injected engine’s ultra-high fuel pressure system, which is nearly 2,200 psi (150 bar) from the camshaft-driven fuel pump. It uses helium to detect the merest whiff of a leak at less than one part per billion.

“The Gen V small-block engines are among the most advanced and high-tech in the world and Tonawanda is now one of the most technologically advanced manufacturing facilities to support them,” said Finch. “From the machining operations and the flexibility for building variants on the same line to state-of-the-art quality advances, Tonawanda’s manufacturing capabilities are second to none.”

This fall, Tonawanda will build its 71-millionth engine, as Gen V production contributes to a daily build rate of more than 1,000 engines. It’s a noteworthy achievement for a plant that has weathered the ups and downs of the industry over the years – and evolved to become not only one of GM’s oldest plants, but one of the most high-tech.

[23]

[23]The revamped Tonawanda plant is geared up to produce more than 1,000 Gen V small block engines each day – and it is scheduled to produce its 71-millionth engine before the end of the year. That’s an average of more than 946,000 engines produced every year.