Making changes to a C6 Z06 Corvette is like trying to touch up the ceiling of the Sistine Chapel – theoretically, the end result can be an improvement, but in practice you run the risk of messing up a good thing. The current Z06 sits in that sweet spot in the Corvette lineup between the semi-race Grand Sport and the supercar killer ZR1, focused on being the best all-around performer and giving incredible bang-for-the-buck. Though it’s already been tailored to be at home on the racetrack, leaving some of the street friendliness of the base and GS models behind, there are plenty of owners who just want a little bit more. More power, more grip, more glorious LS7 music.

So how do you top off a glass that’s already full to the brim? That’s the problem we faced with our 2011 Z06 Corvette. Leaving well enough alone wasn’t really an option, since we’re not Consumer Reports and you didn’t come here to read about the stock ‘Vette, cool though it may be. Instead, we had to find a few select upgrades that would boost performance without taking anything away from the car’s near-perfection in stock form. To accomplish that painstaking task, we turned to three of the most-respected companies in the aftermarket: K&N, Corsa, and Mickey Thompson Tires.

Everything is Better with Carbon Fiber

Our first modification to our Z06 is the same as pretty much every Corvette owner’s – a high-flow intake. While the engineers at GM have done a very good job with the stock snorkel, they have a few design parameters that are at odds with having the best intake flow of clean air possible. They need to come up with something that can be manufactured within a set budget in large quantities, contributes to keeping the total engine noise below the mandated threshold, and apart from filter changes, won’t need to be touched for the expected lifespan of the car.

Every kit that K&N develops is based off the dyno – Bert Heck, K&N

Aftermarket manufacturers, on the other hand, have a free hand when it comes to designing an intake system, and it shows in the wide variety of different models (with an equally wide variety of claimed benefits) available. In our case, we settled on K&N because we know from past experience that their systems are engineered, rather than simply drawn up. We’ve found that their horsepower claims are repeatable on our own in-house Dynojet chassis dyno, and the quality, fit, and ease of installation are all first class.

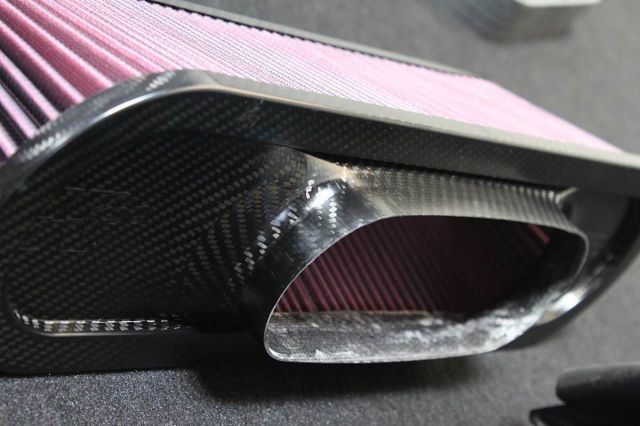

“All of our kits are vehicle specific,” explains K&N Performance Kit Manager Bert Heck. “We don’t make a universal kit.” For our installation, we sourced a K&N 63-Series Aircharger Kit PN 63-3060-1 that uses a molded polycarbonate body and a very large oiled gauze filter element with a top and bottom made out of carbon fiber for lightness and strength. K&N says this intake is good for an estimated 27 extra horsepower at 5,600 RPM.

Per Heck, “Every kit that K&N develops is based off the dyno. Each time we made a change to the tube or the filter, we re-baseline the car stock, then put the changed prototype part on and dyno it again. For lack of a better word, this helps keep the car from getting “confused” because it’s seeing all these changes, and sometimes the numbers will go all over the place. There’s hours and hours of dyno time in developing a kit.”

As you'd expect, the installation of the K&N intake begins with the removal of the stock intake. The factory system uses a blue synthetic media filter in place of the paper element we have come to expect.

Before any testing can begin, though, the prototypes have to be created in the first place. “We start by looking at the packaging. We pull out the stock stuff and look to see where we can put the filter and what we can do with the tube,” says Heck. For the C6 Corvette, with its low hoodline and limited space in the engine bay, the layout was critical. “We knew that the intake would have to go over the core support. Would it be cool to split it and put a filter on each side? We actually made a prototype part like that, along with one that looks like what we ended up with, and after it was all said and done, well, you can see which one the car liked better.”

Even with the dual-versus-single question resolved, more testing was required to figure out what that single filter should be. Per Heck, “We ended up making a new filter for it. We looked at bringing it back to [a round duct profile] where we could use a round, clamp-on filter, but we made a rapid prototype filter base in the oval, and it liked that better than it liked the round base.” With that decided, yet more prototyping refined the internal aerodynamics; “Another thing that picked up some horsepower is that inside the tube there is a plastic insert that acts as sort of a diverter, just past the filter.”

Seen side by side with the stock intake, the K&N clearly shows that it's presenting an easier path for incoming air, which no longer has to navigate the corrugations of the stock unit.

Installation of the K&N intake and replacement of the stock sensors, PCV connection, and mounting grommets is the work of but a few moments.

The final steps in designing a kit make sure that it works not just on the dyno, but on the road as well. “Once we get a prototype that we like, that makes the horsepower we are looking for and fits the package, we put the car back to stock and take it on about a 60-70 mile roadtrip and log all the data off the computer,” says Heck. “Then we take the prototype part and run the same course, half freeway, half city. We come back and overlay the data against stock and see if the car is happy or not. We could make a lot of power, but if the car is running too lean, too rich, if there’s a lot of heat soak, then we start all over. We’ve had prototypes for some cars that made 40-50 horsepower, but the minute we put it on the street and we looked at the data, with the way the data went out of bounds we knew we would have a “Check Engine” light issue.”

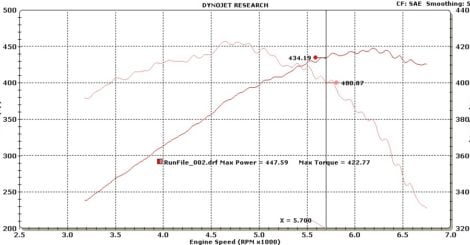

Examination of the before (left) and after dyno results shows we went from 447.59 horsepower and 400.07 pound-feet of torque stock to 470.85 and 440.70 - an increase of 23.26 horsepower and a whopping 40.63 pound-feet. Click to enlarge the graphs...

With our documented success getting more air into the LS7, we turned our attention next to letting more exhaust out. For that, we enlisted the help one of the more popular names in Corvette exhaust systems – Corsa Performance.

Stainless and Painless

Our Z06 came factory-equipped with a dual-mode exhaust system; based on the “map” in the powertrain control module, it will either direct spent gasses through the mufflers’ baffles (at idle and part throttle) or open wide to give them a straight shot at the outside world (and everyone’s eardrums). Colloquially known as “mild to wild,” many Corvette owners disable the system and keep the silencers uncorked all the time, but even this zero-dollar mod has some downside.

One good thing about this swap is that dual-mode factory exhaust take-offs generally sell for a decent price to C6 owners looking to upgrade from the base model's system.

As a result of much acoustic testing, the Z06/LS7 system has mufflers very specific to that application. – Dan Lopez, Corsa

“As most owners know, the stock system drones terribly if the valves are left in the open position,” says Corsa Performance Senior Engineer, Dan Lopez. Not only that, but with the system locked open, you’re carrying around the weight of the actuator system for no good reason, too. From past experience, we know that Corsa Corvette exhaust systems make horsepower, sound great, and don’t make you wish for earplugs on long drives, so they were an easy choice for our Z06 as well. Making things simple, unlike their exhausts for earlier Corvette generations with several muffler options, for our Z06 they offer just one choice – part number 14164.

Lopez explains, “That vehicle is offered with only one sound level because it’s fairly aggressive stock with the valves open, so we didn’t want to be quieter. We were able to tune the mufflers to be aggressive outside yet comfortable and drone-free on the inside. This was particularly important on this vehicle, being more performance oriented, as owners who frequent track events wanted something robust enough for racing, but civil enough to drive home.”

The Corsa axle-back system is easy to install, and comes with everything you need including clamps, hardware, and even caps to seal the unused vacuum lines for the stock dual-mode actuators.

While the mufflers bear a resemblance to the ones used for Corsa’s “Sport” system for LS2 and LS3 Corvettes, Lopez points out that they’re bespoke for this particular car. “As a result of much acoustic testing, the Z06/LS7 system has mufflers very specific to that application,” he points out. “That system is built using straight-through 3-inch diameter premium stainless steel tubing, leading to a hydro-formed transition keeping the cross sectional area consistent, and exiting with twin 4-inch pro-series tips per side.”

As far as weight saving goes, GM gave it all they had with a stock system built from titanium, but even so, Corsa was able to best the factory in less-pricey-yet-still-premium stainless steel. The axle-back system, like we are employing here, comes in 2.4 pounds lighter than stock, and going to the optional Corsa crossover pipe lightens things up by another 2.5 pounds, taking the entire system from 71 pounds to just over 66. “As you can see there are weight advantages, and by eliminating the need for the valve hardware, there are no mechanical parts to fail,” Lopez points out. “Even more impressive are the air flow advantages: a 45% flow increase when compared to stock valves open.”

With the new Corsa cans installed and aligned, it was time to head back to the dyno to gauge our progress.

Harnessing the Power: Mickey Thompson Tires

To help get our Z06 out of the starting blocks a little quicker, we sourced a pair of Mickey Thompson ET Street Radials in 305/35R19 size to fit our stock rims in place of the OEM Goodyear Eagle F1 325/30R19 run-flats. Mickey Thompson Tires has been working hard over the past few years to fill out their line of drag radial tires to cover appropriate sizes for pretty much every modern performance car out there. It’s not easy building a very-low-profile tire that will hook at the dragstrip, but by paying close attention to both the tire carcass design and the rubber compound, M/T has managed to pull it off.

The Final Test

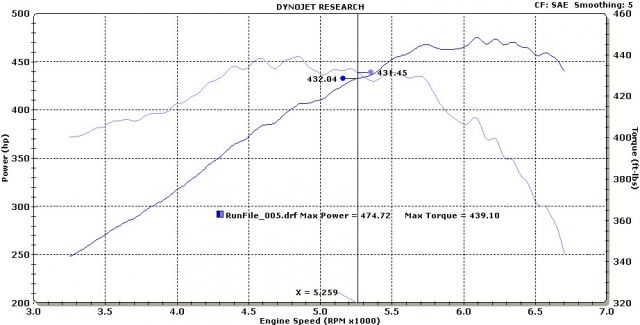

With both the K&N intake and Corsa axle-back exhaust installed, we went back to our trusty Dynojet chassis dyno and spun the roller once more to see where we ended up. The final tally was 474.72 horsepower and 439.1 pound-feet of torque at the rear tires – a gain of four ponies compared to our previous intake-only pull, and an overall gain of 27.13 horsepower and 39.1 pound-feet over our stock baseline runs.

Considering how free-flowing the stock dual-mode system is when it’s in straight-through mode, we were pleased with our results – where a good aftermarket exhaust really shines is once you get into the power realm where even the wide open stocker becomes a bottleneck, and we’re not quite there yet. That, of course, begs the question of just how much power you can make and still not reach the limits of the Corsa system.

“Any exhaust on an extreme horsepower vehicle will add some restriction and reduce efficiency, but the goal is to minimize this affect with the least restrictive system flow characteristics,” Lopez explains. “Since Corsa’s design is straight-through dual 3-inch tubing with no valves, baffles, packing, or chambers, it will be equally as efficient as running straight pipes with the same exit location. That said, many Corsa Z06 customers (for example, Lingenfelter’s 427 twin turbo package) are running over 800 horsepower with this exhaust and are enjoying the acoustic and performance benefits.”

The final tally was 474.72 horsepower and 439.1 pound-feet of torque at the rear tires - a gain of four ponies compared to our previous intake-only pull, and an overall gain of 27.13 horsepower and 39.1 pound-feet over our stock baseline runs.