Congrats on making it to the fifth and final episode of Centerforce University [1]. In the last four installments, you’ve learned the basics of how a clutch works, how to properly break-in a new clutch, how to pick the proper flywheel, and how to choose a clutch for your high powered street machine. For your final, the faculty from Centerforce Clutches [2] will take you through Clutch Technology for Maximum Performance [1] vehicles.

[3]

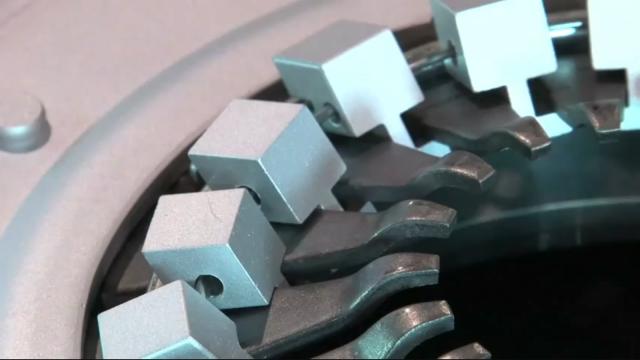

[3]Dual friction discs and 6-pucks, like the Centerforce DFX [4], are two typical designs for racing clutches.

So you’ve got a race car and a stock style clutch just isn’t going to make the grade. You need a high powered clutch, but typically that would mean dealing with a super hard pedal, and other drivability issues. Centerforce “Professor” Will Baty tells us, “Using a heavy or stiff diaphragm to increase clamp load on the pressure plate is usually what makes the pedal so stiff with traditional high-torque clutches. This also affects the deflection the diaphragm has making the clutch more like an On/Off switch; either you have full power all at once, or not at all with very little modulation in between.”

[5]

[5]A cool and unique feature of Centerforce's race clutches is their patented pressure plate weight system. As the clutch spins faster and faster, the weights clamp down tighter and tighter on the diaphragm fingers thanks to centrifugal force.

Centerforce [2]’s clutches are different because in many cases you can have the high torque capacity you’re looking for, with very good drivability thanks to their patented technologies. Centerforce’s ball bearing technology allows for a lighter pedal feel by lessening the friction on the internal ridges of the pressure plate. Additionally, better friction materials and more clamp load give their clutches better holding capacity, meaning they can reduce the internal friction which in turn also gives a better pedal feel.

[6]

[6]Another patented Centerforce technology is the ball bearings they use inside the pressure plate to reduce friction and help keep pedal effort light.

If you’ve got a blown and injected beast that chews up and spits out clutches, then check out the Centerforce DYAD twin disc clutch. [4] The DYAD is capable of harnessing up to 1,300 pound feet of torque. “The key to the DYAD is its friction material, which is a carbon based organic material,” Baty explains. “It’s the reason the clutch can hold so much torque, and a key to the light pedal effort. We have spent over two years of developing the DYAD to make it one of the best clutches available today.”

Well, that’s it for us here at Centerforce University [1]. Now that you’ve graduated with your Master’s in Friction Technology, you’re ready to head out to leave your mark on the world – two thick black tire marks that is…