[1]It seems that whenever late model Corvette handling comes up in conversation, there will inevitably one person armed with just enough knowledge to be dangerous who will say, “I can’t believe they still use leaf springs! That’s donkey cart technology!” While it’s true that leaf springs have been around since medieval times [2] (the era, not the theme restaurant), as used in the modern C5, C6, and C7 Corvette, they offer some pretty enticing benefits.

[1]It seems that whenever late model Corvette handling comes up in conversation, there will inevitably one person armed with just enough knowledge to be dangerous who will say, “I can’t believe they still use leaf springs! That’s donkey cart technology!” While it’s true that leaf springs have been around since medieval times [2] (the era, not the theme restaurant), as used in the modern C5, C6, and C7 Corvette, they offer some pretty enticing benefits.

[3]The composite monoleaf springs are light, and what weight they do have is very low in the car, leading to a better center of gravity. They don’t have as much unsprung weight as an equivalent conventional coil spring suspension. And thanks to the split body mounts, they offer a measure of roll resistance, allowing for smaller, lighter anti-roll bars on both ends.

[3]The composite monoleaf springs are light, and what weight they do have is very low in the car, leading to a better center of gravity. They don’t have as much unsprung weight as an equivalent conventional coil spring suspension. And thanks to the split body mounts, they offer a measure of roll resistance, allowing for smaller, lighter anti-roll bars on both ends.

With all that going for them, why would someone want to bin those springs and switch to a coilover suspension [4]? In a word, adjustability. Replacing the monoleaves and shock absorbers with coil-over-damper units (which everyone simply calls “coilovers”) gives you the opportunity to control ride height within a far greater range of adjustment than turning bolts on the stock leafs, use damper bodies with adjustable valving, and even change spring rates with relative ease at a low cost. For all these reasons, a Corvette coilover swap is the go-to suspension setup for serious track aficionados.

NASA-Level Engineering, Budget-Friendly Cost

[5]When we reached the decision point when mapping out our suspension plans for Project Y2k [6], our in-house 2000 C5 Corvette, we wanted the advantages of an adjustable suspension, but we also wanted to remain true to our theme of a “blue collar supercar” by staying on a budget that buyers of older Corvettes could relate to. We also didn’t want to wreck the daily-driver goodness of the car with a suspension that was harsh, noisy, or impractical for street use in a world with pavement that was less than pool-table smooth.

[5]When we reached the decision point when mapping out our suspension plans for Project Y2k [6], our in-house 2000 C5 Corvette, we wanted the advantages of an adjustable suspension, but we also wanted to remain true to our theme of a “blue collar supercar” by staying on a budget that buyers of older Corvettes could relate to. We also didn’t want to wreck the daily-driver goodness of the car with a suspension that was harsh, noisy, or impractical for street use in a world with pavement that was less than pool-table smooth.

To help us out, we enlisted the help of Pfadt Race Engineering [7], a recognized leader in Corvette performance upgrades. Based in Salt Lake City, Utah, Pfadt offers suspension and engine upgrades for 1997-present Corvettes, 5th gen Camaros, and the Cadillac ATS. More specifically, they offer a number of different suspension packages for our Corvette, ranging from upgraded anti-roll bars and conventional shocks all the way up to full-race double adjustable coilovers with remote reservoirs. They even offer a coilover package engineered specifically for drag racing applications, should that be your area of focus.

One option we considered was using Pfadt’s FeatherLight Generation single-adjustable shocks with our existing Z51 leaf springs, but in the end decided on the FeatherLight Generation single-adjustable full coilovers. For the relatively small increase in overall price, the coilovers would also give us the aforementioned ride height adjustability and easy spring rate selection.

Because we would be trading away the roll stiffness benefits of the transverse leaf arrangement, we also decided to replace the stock Z51 package anti-roll bars front and rear with a pair of Pfadt’s Johnny O’Connell sway bars. Pfadt’s Blair Sonnen explains, “With Pfadt coilovers you will gain a more smooth, predictable and precise ride over stock. The coupling that is present in the leaf contributes to adverse handling characteristics.”

“While this is OK on stock street applications, it leaves a ton on the table for race track use and serious street performance. The leaf itself also has a non-linear spring rate which adversely affects handling when you are in a turn and hit a bump. Many Corvette owners have experienced this, and it can be particularly upsetting at speed. Coilovers allow the coupling from left to right sides to be limited to the sway bar (or anti-roll bar, more accurately) where it can be much more consistent and tunable for precise balance control.”

All together, the coilovers and bars make up a package that will vastly improve the precision of Y2k’s suspension, without breaking the bank (or our spines!)

Not Your Everyday Coilover

While the concept of a coilover conversion for race duty has been around a long time, in the general world of automotive enthusiasts, coilovers don’t necessarily have the best reputation. This is largely because of shoddily-engineered kits that flooded the market when the Fox-body and SN-95 Mustangs were at the peak of their popularity. One look at the Pfadt units will tell you that these are a far cry from the noisy, rusty, harsh coilovers that gave the whole idea a bad name, but it takes some deeper inspection to see just how different they really are.

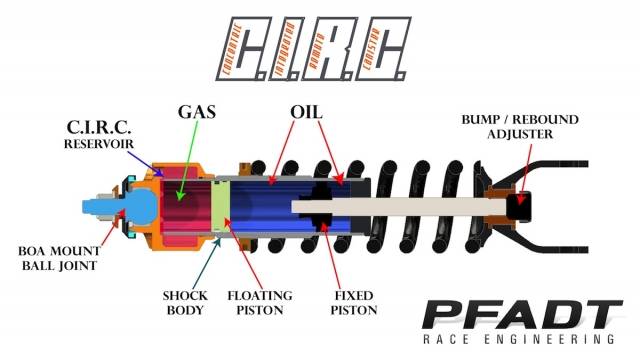

Diving into the details, you’ll notice the “inverted” design that puts the majority of the mass on the chassis side of the suspension, keeping unsprung weight low. They’re constructed of lightweight aircraft-spec aluminum, which provides both corrosion resistance and strength. But the big things that set the FeatherLight Generation coilovers apart from conventional designs are CIRC and BOA. These two acronyms stand for Concentric Integrated Remote Canister and Ball On Axis, respectively, and the technology they represent are the keys to Pfadt’s performance.

[13]The CIRC system allows more than three times the pressurized gas volume of a conventional coilover damper, while still maintaining excellent shock travel and full range of motion much like a traditional remote reservoir shock. The design accomplishes this by surrounding the upper portion of the damper tube with a concentric chamber that acts as the gas reservoir.

[13]The CIRC system allows more than three times the pressurized gas volume of a conventional coilover damper, while still maintaining excellent shock travel and full range of motion much like a traditional remote reservoir shock. The design accomplishes this by surrounding the upper portion of the damper tube with a concentric chamber that acts as the gas reservoir.

“Not only do we have gas pressure in the normal volume above the oil, but it also bleeds over into a reservoir that actually encompasses part of the shock body itself,” Sonnen says. “This allows for more nitrogen and oil volumes to work with internally, and that results in a comfortable street damping rate that doesn’t jar your kidneys when driving to dinner on a Saturday night.”

The Pfadt design also separates oil and gas with an internal floating piston for greater damping precision. “The floating piston design is exactly as it sounds – a floating piston internally, but its function is to separate the oil and nitrogen,” says Sonnen.

[14]

[14]Rather than using the typical jam nut collar to secure the spring perch, Pfadt employs a threaded perch with an integral setscrew for simpler ride height adjustment.

“When you separate these two things internally, you reduce the possibility of oil cavitation due to the elements not being mixed. Oil and nitrogen are mixed in an emulsion shock, and they typically suffer from two things: inconsistent damping characteristics that vary according to shock temperature, and an “air spring” effect that comes from oil and nitrogen being mixed together and trying to pass through orifices in the piston.” With the liquid and gas kept separate by the internal piston, each can do its job with greater precision and control.

Per Sonnen, the BOA mount is a clever engineering solution to a common problem: How do you provide articulation in the top coilover mount? “A typical Corvette upper mount will either use a clevis-style or a ‘pin-top’ mounting solution,” he explains. “The problem with the clevis-style is that it drastically reduces the amount of suspension travel in the shock absorber, and the Corvette packaging area is an already-tight space to work in, where every millimeter counts. When you reduce the suspension travel, you wind up having to use stiffer springs to keep the car from bottoming out frequently on common road environments. Increasing the spring rate is never a good idea for our customers, unless you are driving a track car. We want a comfortable ride that soaks up bumps and keeps you planted in the corners.”

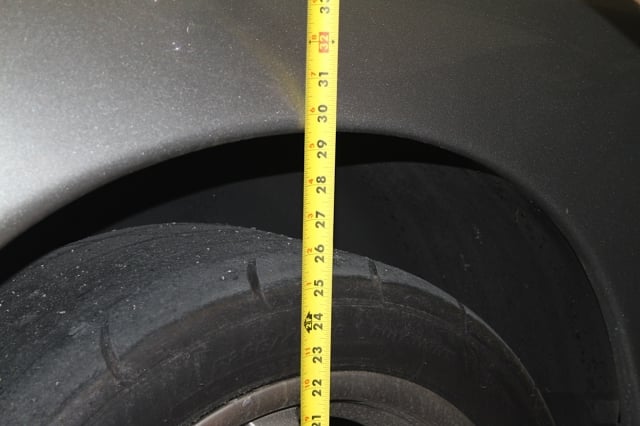

Before we began, we measured the stock ride height to the top of the fender arch, back and front. And yes, we have been hitting that drag radial hard...

All of your spring and shock forces are acting efficiently on the chassis and not being lost in any rubber. – Blair Sonnen, Pfadt

The BOA mount eliminates the compromises in these mounting solutions – per Sonnen, “We take the simple concept of a control arm ball joint, and integrate it into the top canister so the result is a pivoting pin that soaks up the articulation needed for the Corvette suspension geometry without deflecting one bit. All of your spring and shock forces are acting efficiently on the chassis and not being lost in any rubber.”

We started off at the back, by unbolting and removing the stock shocks.

Easier Than it Looks

The actual work involved in this swap is less daunting than you might think; a DIYer’s toolbox, a set of jackstands, and a driveway will suffice, though we will admit we are spoiled because we have access to some spiffy two-post lifts that make jobs like this easier. One aspect of the Corvette’s stock suspension design that makes this considerably easier is the fact that unlike factory coil spring setups, there’s no bear-trap tension lurking in the spring mounts, waiting to bite you.

One area of Corvette mechanics that's easier than on lesser cars - spring removal...

Backing off the adjusters with the suspension at full droop takes all but a fraction of the tension out of the leaf springs, leaving just four bolts per spring to remove. There’s no janky borrowed coil compressor to worry about breaking or slipping, and the coilovers, with their captive spring, go right back in just like shocks would. The entire process, including mounting the sway bars, is an easy Saturday in the garage, and if you have enough of a sense of self-preservation to not pull the car down off the jackstands on top of you, you’ve cleared the one major safety hurdle involved.

After transferring the stock upper mounting plate to the coilovers, they go right back in place of the shocks.

The front suspension is just as simple as the rear.

As for the initial adjustment, Pfadt has that covered right out of the box. “We ship every set of coilovers at our ‘street performance’ settings,” says Sonnen. “They are an instant bolt-on that will give you a massive increase in handling and ride control. Of course, most of our customers prefer to adjust their coilovers at some point, so our instructions illustrate exactly how to achieve race-specific settings with the option to always return to our initial street performance settings.”

The anti-roll bars went in front and rear as well, with the rear bar set to the middle position on the end links.

With everything bolted in place and the alignment checked, we tentatively took to the road to see how we’d done. While SoCal doesn’t suffer from road salt, frost heaves, or the ravages of the snow plow, decades of underspending on infrastructure means that our roads can compete with any cratered moonscape in the country. We turned the key and pulled out of the shop, braced for impact, and… Well, nothing.

[34]In this case, “nothing” means “ride quality as good as or better than what we had before.” No jarring bump-stop impacts, no rattles and squeaks, no nastiness of any sort. As a matter of fact, there’s nothing to hint that this car has a coilover conversion – until you start to ramp up the lateral g forces, that is. While our current tire combination didn’t allow us to fully explore how our coilover and anti-roll bar combination affected front to rear balance, we did note a noticeable reduction in body roll and sharper turn-in. Full exploration of the limits of our new suspension will have to wait for something other than street tires on the front and drag radials out back, but it’s safe to say that Pfadt has already reset our expectations about coilover suspensions. We can’t wait to give our blue collar supercar a real workout!

[34]In this case, “nothing” means “ride quality as good as or better than what we had before.” No jarring bump-stop impacts, no rattles and squeaks, no nastiness of any sort. As a matter of fact, there’s nothing to hint that this car has a coilover conversion – until you start to ramp up the lateral g forces, that is. While our current tire combination didn’t allow us to fully explore how our coilover and anti-roll bar combination affected front to rear balance, we did note a noticeable reduction in body roll and sharper turn-in. Full exploration of the limits of our new suspension will have to wait for something other than street tires on the front and drag radials out back, but it’s safe to say that Pfadt has already reset our expectations about coilover suspensions. We can’t wait to give our blue collar supercar a real workout!