According to the folks at COMP Cams [2], valve springs are the most highly stressed components in any engine. Improper handling of valve springs can lead to reduced life, because of the how stresses occur during operation. As the spring is compressed, the coil also twists with the result that the outside surface of the wire is in tension.

[3]

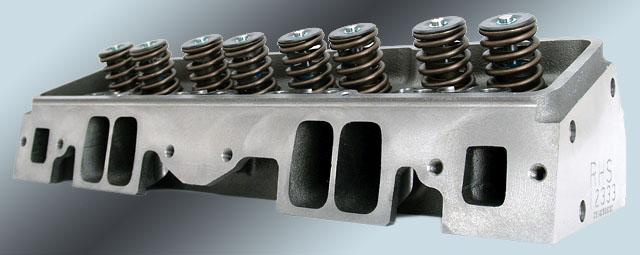

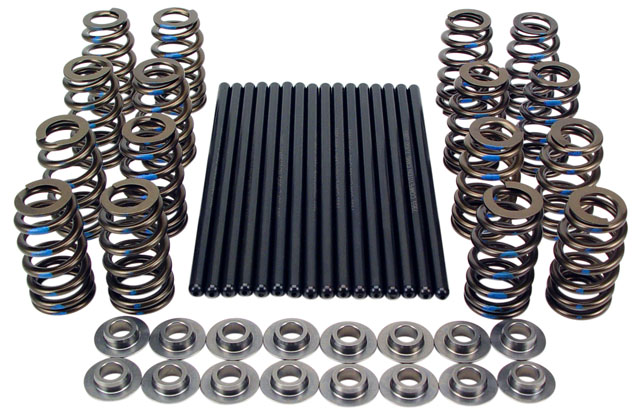

[3]Valve trains are designed as a system, so it's important that the spring is compatible with other components being used.

COMP Cam’s R&D engineer, Bradley Brown, explains in the video below that anything which damages the outer surface of the wire can reduce the number of cycles over which the spring will reliably operate. Keeping valve springs light is an ongoing challenge, but lighter springs reduce camshaft wear and allow for higher engine RPM, which can mean more power.

To achieve the lightest, high performance valve spring, COMP Cams’ springs are designed and manufactured for a specific number of cycles depending on their intended application – drag race means this many cycles, street means this many cycles and so on. As a result, any mishandling that damages the outer surface of the wire can cut down the number of cycles that the spring is capable of handling.

While handling of the springs during installation, removal and storage is important, getting the right springs and other valvetrain components is equally critical to success. Such components are not universally interchangeable. Valve trains are designed as a system, so it’s extremely important that the spring be matched to the other components being used.

COMP provides extensive information in their printed catalog, as well as through their free tech line, to help you get the right stuff into your engine. Check out the video below to see what else Bradley has to say. You’ll be quite surprised at how easily you can improve your valve spring life.