According to Comp Cams [2] R&D engineer, Bradley Brown, the number one killer of rocker arm life is valve train instability. Determining the correct pushrod length is critical to proper installation. Brown takes you step-by-step through the process using a Comp Cams adjustable length pushrod tool, also known as a checking pushrod.

[3]COMP Cams’ checking pushrods make it easy and economical to determine proper pushrod length during any high performance engine rebuild. Precise length measurement is necessary for correct valve train geometry in order to obtain the desired results from the cam and to ensure damage is not done to the rest of the valve train.

[3]COMP Cams’ checking pushrods make it easy and economical to determine proper pushrod length during any high performance engine rebuild. Precise length measurement is necessary for correct valve train geometry in order to obtain the desired results from the cam and to ensure damage is not done to the rest of the valve train.

Extensive research at COMP Cams previously determined that factors beyond simple strength become more important as camshaft profiles become more aggressive and valve spring forces continue to grow. According to company engineers, the frequency of the pushrod must match that of all the rest of the parts in the valve train, as well as the rpm at which the engine will be run.

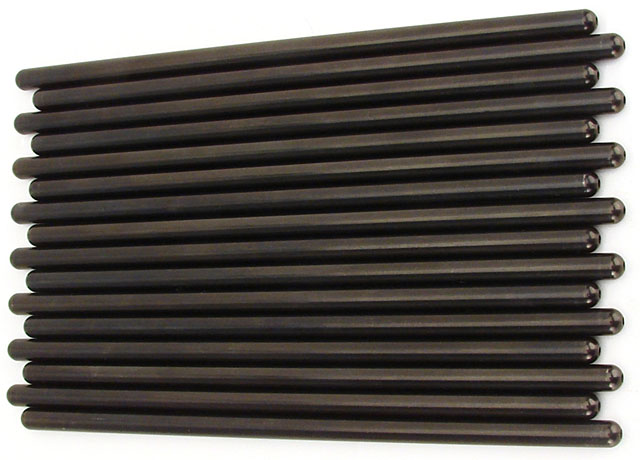

Beyond the design phase, exacting standards have long been in place to ensure that Comp Cams’ pushrods exceed all requirements and provide consistent performance from one lot to the next. Made from SAE 4130 chrome-moly steel, the company uses sophisticated manufacturing equipment and processes to deliver the best product possible.

COMP Cams manufactures a wide selection of precision pushrods to handle any application from street performance to hardcore race. Although COMP Cams’ pushrods are superior in every aspect, their engineers are never satisfied. R&D continues in the quest of making them better and, when there’s a way to improve pushrods, COMP Cams will be first to make it happen.