Safety wire is a positive locking device that is simple, economical and easy to use. This locking device guards against vibrations from imbalances in the rotating parts and uneven friction from loosening fasteners.

When it comes to positive locking devices, safety wire is a useful item that prevent fasteners from loosening up during operation. Vibrations, especially higher frequency vibrations, can cause fasteners to loosen or disengage due to the vibrational motions generated by mechanical devices like engines or suspension systems. To prevent these fasteners from disengaging, positive locking devices like cotter pins, tab washers, lock plates and safety wire are used.

Cotter pins are simple, easy to use and cost effective. They work well on with split beam and castellated nuts to provide a positive lock. The problem with cotter pins (split pins) are when there is no access to the recepticle end of the fastener or blind bolt holes where the treads are tapped into the component. Installing a cotter pin on the bolt head has no affect what-so-ever. This is when safety wire can be used as the simple and cost effective locking device. Using some basic methods, safety wire is a practical method of preventing screws, bolts, oil caps, drain valves and other fasteners from loosening.

Examples of safety wire as a positive locking device used on a series of bolts. Photo from www.FAA.Gov Click on image to enlarge.

Lock Wire

Generally speaking, 0.032-inch stainless steel wire is used for racing purposes as the preferred diameter wire. When the parts are too small or where limitations preclude the use of the larger wire, 0.020-inch or 0.025-inch stainless wire is often used.

The most common method of installing safety wire to fasten multiple groups of fasteners consists of two strands of wire twisted together, often referred to as “double strand” or “double twist.” To install the lock wire, the wire must be pulled taut while being twisted. The number of twists per inch depends on the size of the wire. The smaller 0.020-inch and 0.025-inch wire diameter performs optimally with 9-12 twists-per-inch. 0.030-inch diameter wire works best with 7-10 twists-per-inch.

More examples of using lock wire as a positive locking device in multiple applications. Photo from www.FAA.Gov Click on image to enlarge.

One twist is defined as being produced by twisting the wires through an arc of 180 degrees and is equivalent to half of a complete turn.

The single strand method of lock wiring may be used for some applications, such as in a closely spaced, closed geometrical pattern (triangle, square, rectangle, circle, etc.) parts in a system.

How To Install Safety Wire

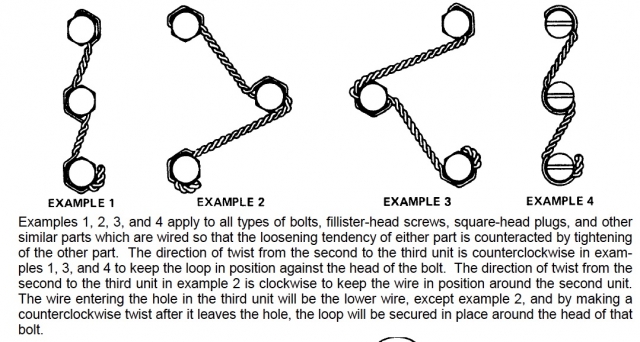

Federal Aviation Administration advisory instructions explains the proper methods of installing safety wire for aviation use. Following these same methods in racing applications is advisable as they are time proven.

There are many combinations of safety wiring with certain basic rules common to all applications. When bolts, screws, or other parts are closely grouped, it is more convenient to safety wire them in series. The number of bolts, nuts, screws, etc., that may be wired together depends on the application. Drilled bolt heads and screws need not be safety wired if installed with self-locking nuts.

Safety wire inside a duct or tube should not cross over or obstruct a flow passage when an alternate routing can be used. When there are two or more units to safety wire, it is desirable that the holes in the units be aligned to each other. Never over torque or loosen to obtain proper alignment of the holes. It should be possible to align the wiring holes when the bolts are torqued within the specified limits. In adjacent bolt heads, it is desirable that the holes be in approximately the same relationship to each other so the lock wire will have a tendency to pull the unit clockwise. This should be reversed for left-handed threads.

To prevent failure due to rubbing or vibration, safety wire must be tight after installation. Safety wire must never be overstressed as the wire will break under vibrations if twisted too tightly.

Safety-wire ends must be bent under (“pig-tailed”) and inward toward the part to avoid sharp or projecting ends, which might present a safety hazard. The wire’s sharp ends can embed or cut fingers, hands or other body parts that come into contact with them. Nicks, kinks, and other damage to the wire are not acceptable.

More information on safety devices and safety wire can be found at the Federal Aviation Administration’s Advisory Circular webpage.