For years, SPEC Clutches [1] has been providing racers and enthusiasts with durable, high performance clutches for everything from small four cylinder engines, to European exotics, drag racing, road course, and truck pulling. We recently came across a video giving viewers and inside look at the company’s Birmingham, Alabama facility. The company manufactures all of their clutch components and flywheels in house at this complex.

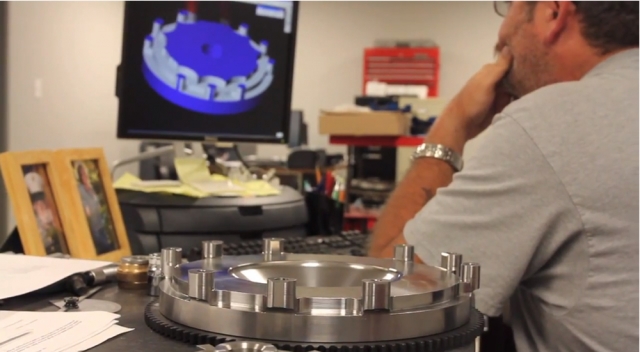

[2]All new components start out in the engineering department where they are carefully designed by experienced engineers using CAD software and tested before being put into production.

[2]All new components start out in the engineering department where they are carefully designed by experienced engineers using CAD software and tested before being put into production.

On the manufacturing floor, all components are balanced individually before being grouped together. They are then balanced together as an assembly to ensure that everything is balanced properly, and will work together. This is demonstrated early on in the video on a GT500 Super Twin clutch. An out of balance clutch assembly can cause vibrations and noise in the drivetrain as well as lead to other problems.

Another fascinating point of quality control is the pressure plate testing station. Here every pressure plate is tested before it goes out the door. They are tested to ensure that the pressure plate is achieving the desired clamping load, actuation pressure, and diaphragm height are all within specification.

Perhaps most fascinating though is the bevy of CNC mills that are creating various components of different clutch systems. We’ve said before that we could state at many CNC mills all day long as they cut and mill their way through various types of metal creating high quality, and highly engineered parts.

SPEC takes pride in the fact that their components are built in the USA and that through strict quality controls they can deliver a high quality product. Check out the shop tour video for more information on what goes into every clutch from SPEC.