The cornerstone of hot rodding has always been the concept of injecting more performance into garden-variety vehicles, and for more than half a century, the Chevy small-block V8 has played a pivotal role in that pursuit. True to form, GM’s LS family of V8 engines has served as the modern interpretation of the classic pushrod recipe for horsepower.

Beyond its place on the assembly lines of General Motors products, the LS series has also become a go-to V8 for engine swaps in everything from C10 pickups to Mazda Miatas.

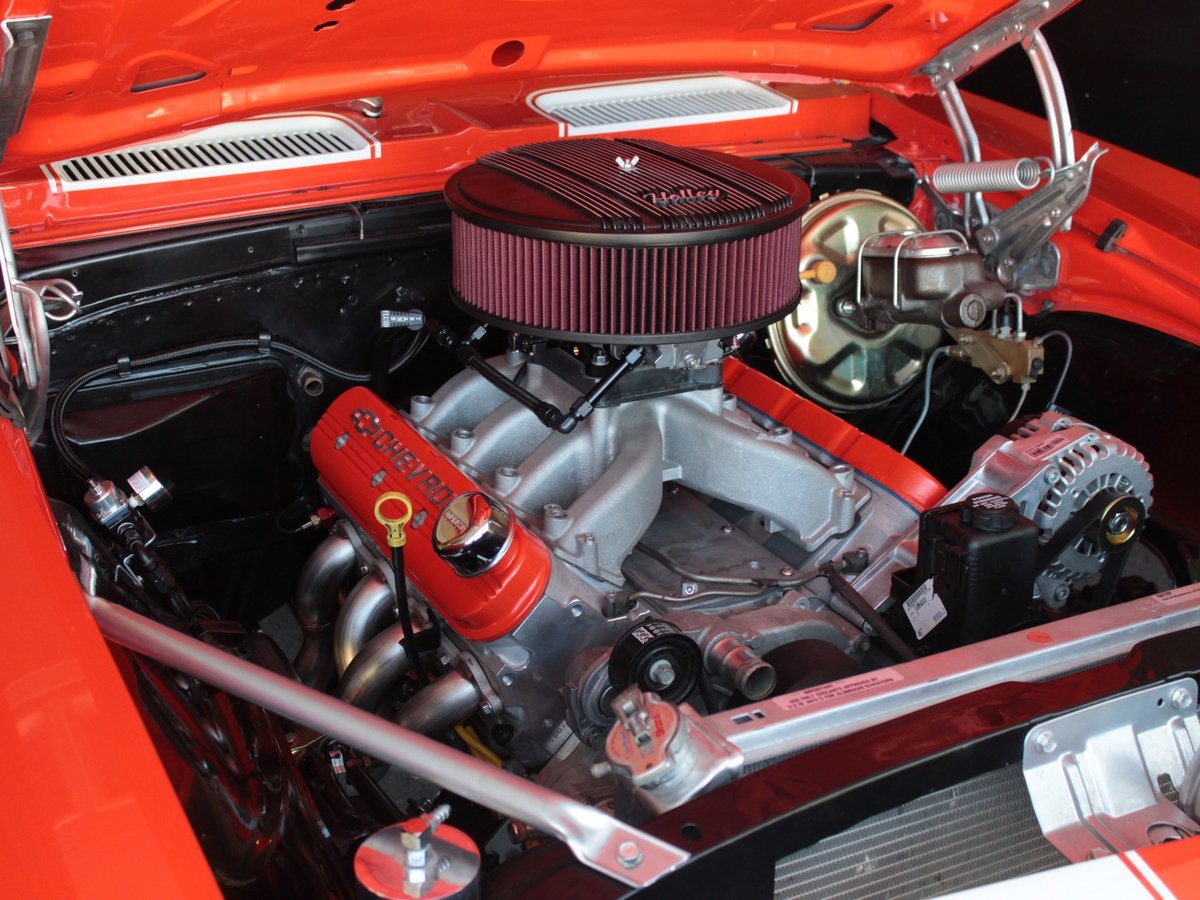

The compact packaging, light weight, and low cost of LS series engines has made them a popular option for engine swaps in all sorts of different late model chassis. More recently, builders of vintage GM models like the Nova and first-gen Camaro seen here have turned to the LS to take both performance and reliability to a level well beyond the best the factory had to offer back in the day.

Literally millions of LS motors have been built over the past 18 years, which makes sourcing one almost effortless. Readily available aluminum block iterations and compact packaging have made LS engines essentially the default motor swap choice for those looking to maintain (or improve) weight balance and add a healthy dose of thrust without having to hack the vehicle apart to get it.

Those same attributes see GM’s modern small-block finding its way into the engine bays of vintage iron in increasing numbers as well, as owners of vintage Camaros, Novas, Chevelles and other GM vehicles have discovered that these modern engines can easily dish out more performance than the majority of the original power plants found in these cars.

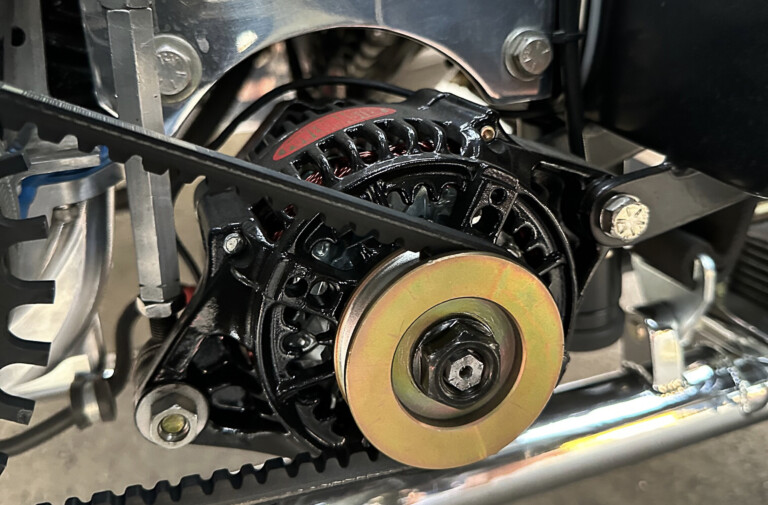

It might seem like a bit of a headache to try to fuse a modern, computer-controlled motor with a vintage chassis, but aftermarket engineering has made the process much easier over recent years. This modern LS looks right at home in this engine bay, despite the mutli-decade discrepancy in their ages.

An accommodating aftermarket helps to make these swaps relatively hassle free, but when it comes time to start wrenching there are some considerations worth your attention, particularly in the realm of the headers you’ll need in order to make modern LS motors fit in vintage engine bays.

We spoke with the folks at Hedman Performance Group, Hooker Headers, and Ultimate Headers to get the details on how LS swap headers are designed for the job, pitfalls when doing an LS swap, and what additional parts you may need to make it all work together.

Fitment Considerations

Although LS series engines are dimensionally similar to old school Chevy small-block V8s, there are a number of external differences in their configuration that make fitting them into vintage chassis more than just a drop-in proposition, especially if the vehicle in question has other modifications that alter packaging in the engine bay.

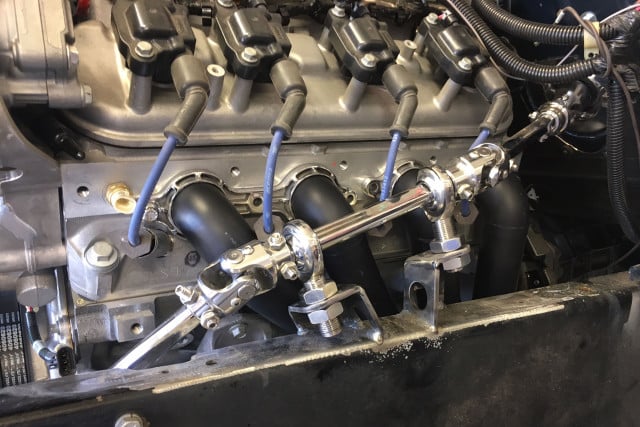

“One of the biggest culprits is the steering setup,” says Hedman’s Marc Lewis. “Due to their larger dimensions, close ratio power steering boxes can interfere with header fit. Another steering issue can occur when builders swap the steering system for a rack and pinion steering system with an in-board pump. In these cases, the steering shaft is angled inward, causing interference with the header tubes.”

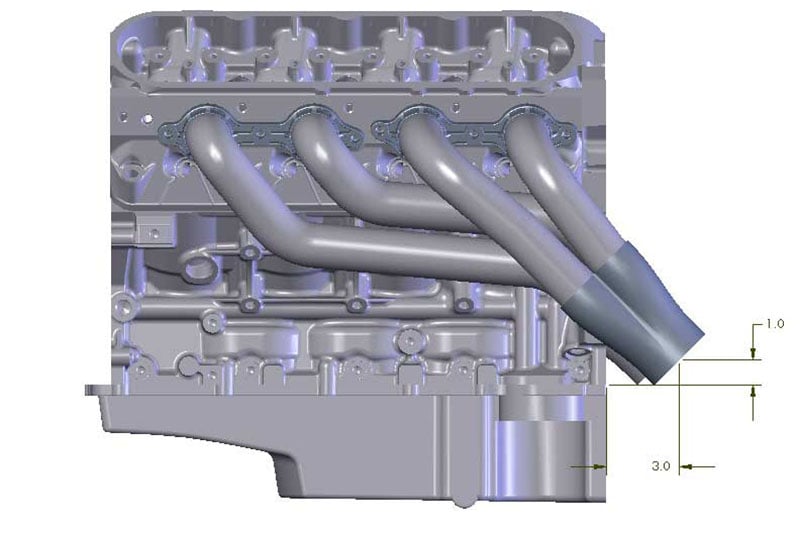

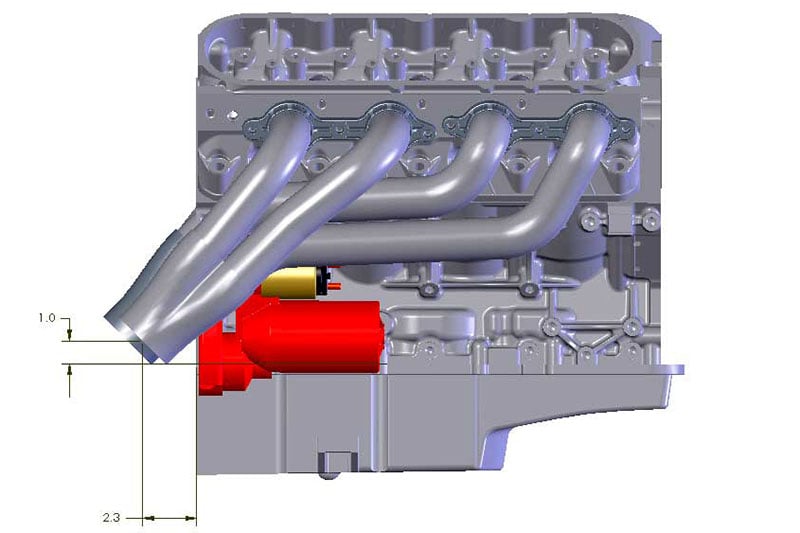

Getting a sense of the space you have to work with before diving straight into the project can save a lot of hassle along the way. Ultimate Headers provides these schematics to show the packaging dimensions of the LS once their headers are added to the equation.

Motor mounts definitely need to be taken into consideration when buying LS swap headers. With short or mid-length tubes, you may have some flexibility, but if a set of mounts raises or lowers the engine, or moves its position fore or aft, header tubes will start impacting A-arms, the firewall, or even the motor mounts themselves. – Marc Lewis, Hedman Hedders

Using the incorrect motor mounts for the combination of parts you have can cause problems too, even if those mounts are designed specifically for LS swaps. “The main issue we see customers having is that they’re using the wrong swap mounts with our headers,” says Keith Jessee of Hooker Headers. “Every swap header we make is designed to work with a specific set of mounts that we also manufacture. Our headers are designed around Hooker LS Swap mounts, and we do not check fitment with other manufacturers swap mounts.”

“Motor mounts definitely need to be taken into consideration when buying headers,” Lewis agreed. “With short or mid-length tubes, you may have some flexibility, but if a set of mounts raises or lowers the engine, or moves its position fore or aft, header tubes will start impacting A-arms, the firewall, or even the motor mounts themselves. With long-tubes, the need for compatible mounts is even more critical. In fact, some of the engine mounts built to be used with some of our long-tube headers are specially constructed to allow clearance for the header tubes. Attempting to install these long-tube headers using a competitor’s engine mount will most likely not work.”

Ultimate Headers’ slogan is “Big pipes in tight places” and that certainly applies to this LSA transplant into a ’39 Hudson. The narrow framerails of the Hudson were proving to be quite a challenge for owner Jim Veite, and he considered having a custom set of headers built to make it all work. But because of the unique construction methods that Ultimate Headers uses to create tight radius bends, their off-the-shelf headers for LS swaps into first-gen Camaros fit the bill without any modification.

Ultimate Headers, on the other hand, takes a slightly different approach when it comes to motor mount compatibility, providing their customers with a more flexible solution. “We model our headers with several different mount manufacturer’s products to make sure they’ll fit for a particular application,” says Jim Browning of Ultimate Headers. “And we also ask the customer when they’re purchasing their headers which mounts they’re using to make sure there’s compatibility. It’s also less of an issue for us because of the way we construct our headers, which allows us to cast an elbow at a tighter radius that you’ll normally find, while preserving uniform wall thickness.”

But it’s also worth mentioning that regardless of how much flexibility a header design might offer, motors mounts can not only alter header fitment, they can also affect transmission crossmember fitment, accessory drive clearance and numerous other things, so it’s critical that the motor mounts selected are the right ones for the particular job.

Hedman Hedders offers not only headers for LS swaps, but full conversion kits for Tri-Five Chevys, GM A-Body, GM X-Body, vintage GM pickups and more, all of which you can find right here.

Port Design

The construction and features of the headers you select for your LS swap project doesn’t just affect the under-hood eye candy of your ride, they can have significant effects on heat management, longevity, and even performance.

“Just because the headers bolt up without interference does not mean they work,” Lewis points out. “Port size and shape does vary, and if you install a small tube header on a large ported head, you will choke the engine, sacrificing power, and they may even leak.”

Although the vast majority of engines in the LS family will use the same headers, there are a few exceptions. The issue comes down to the cylinder heads, and certain high performance LS motors like the LS7 seen here use a slightly different exhaust port design. Even though they may bolt up correctly, using the wrong headers here will cause a choke point where the headers hook up to the heads, which will likely cause a loss of performance and create exhaust leaks.

For the most part, all stock LS heads will use the same headers, but the LS7 heads and some of the aftermarket racing heads have a slightly larger port that is shaped differently and will require you to do your homework to make sure your headers will work. – Keith Jessee, Hooker Headers

Primary Diameters

While there’s isn’t a “one size fits all” solution, there’s something of a general guideline to follow, and it’s largely dependent on engine output and application.

For street cars, primary diameters generally range between 1-1/2- to 1-7/8-inch diameter primary tubes, while racing applications can occasionally call for 2-inch primaries.

“In our research we’ve discovered that 1-7/8-inch primaries cover about 95 percent of the engines that are built,” said Browning.“We’ve seen 950 horsepower pro-touring builds which still use that diameter size effectively.”

Hooker Headers provides not only headers for LS swap projects, but full conversion kits, which include motor and transmission mounts, crossmembers, starter and fuel line heat shields, and a complete stainless exhaust system to help simplify the job for the builder. Along with kits for first- through fourth-generation Camaros, they also provide conversion packages for GM A-Body, X-Body, G-Body, C10 and even the Nissan 240SX, all of which you can find here.

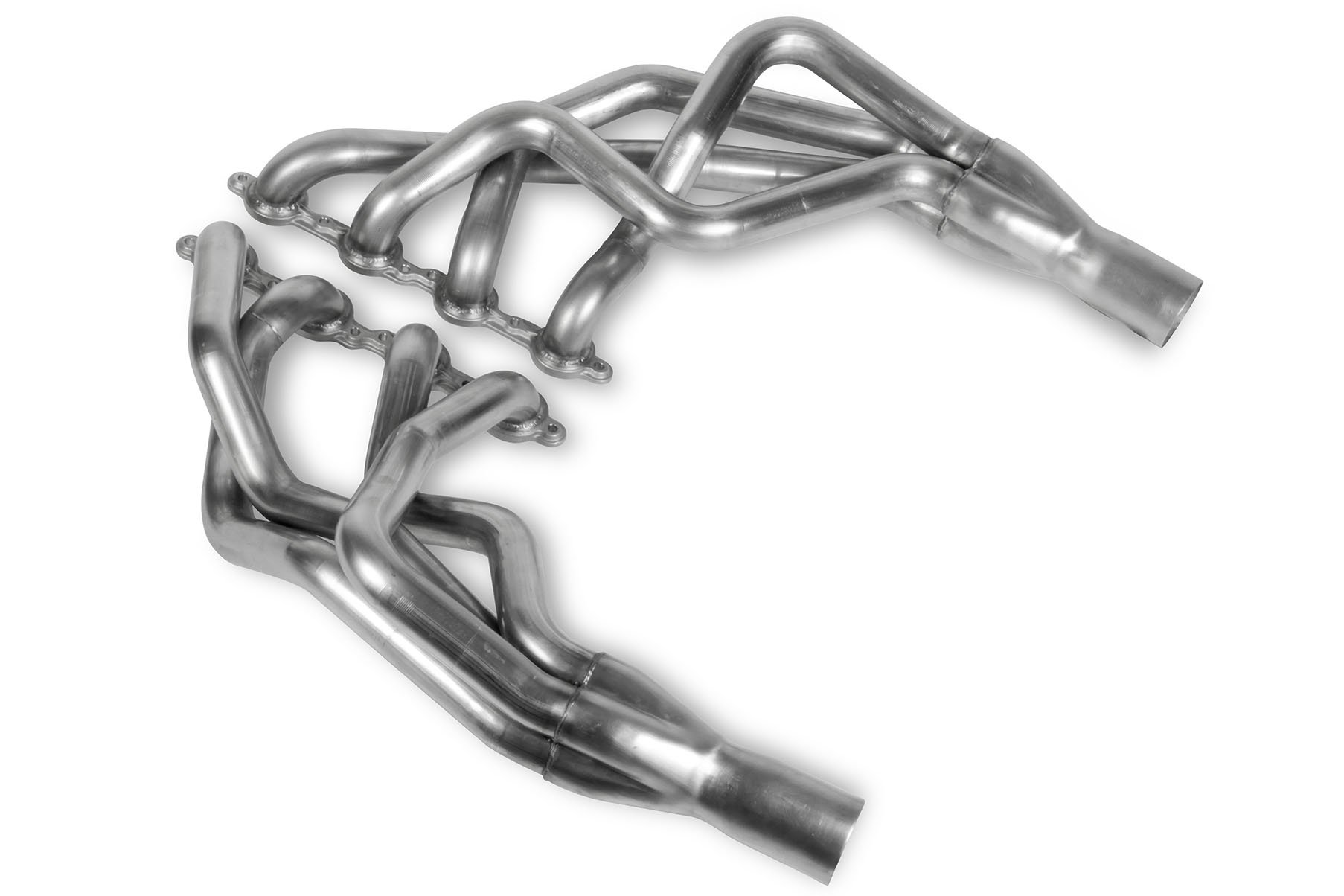

Hooker and Hedman’s offerings echo that sentiment as well. “The majority of our LS headers are going to be available in 1 3/4-inch and 1 7/8-inch primary tubes with 3-inch collectors,” Jessee tells us. “The main reason for this is those sizes tend to make the best power on most LS engines, and these are the sizes that people are asking for.”

In more extreme cases, a larger primary tube diameter may be needed to get the most out of the engine, but this usually goes well beyond your typical warmed-over street machine motor. “For race engines, Hedman’s motorsport division manufactures LS swap headers up to 2-inch long-tubes, including 1-7/8 x 2 inch stepped tube models,” Lewis explained.

Although it’s tempting to move up to massive tubing if your motor puts out a lot more power than it would in stock form, most exhaust manufacturers agree that anything beyond 1-7/8-inch primaries are overkill for the vast majority of engines outside of purpose-built racing applications. All of Ultimate Headers offerings use 1-7/8-inch tubing from end to end, and they’ve seen that work effectively with motors making nearly 1,000 horsepower.

Construction

When it comes to the materials used for header construction, both Hedman and Hooker use mandrel bent mild steel and 304 stainless steel–depending on customer preferences and application. 304 stainless is a very durable material and resists rusting and corrosion almost indefinitely. Ultimate Headers, however, serves as an outlier amongst the three companies profiled here, as they use 321 stainless steel to build all of the header offerings.

“321 stainless is more resistive to thermal cracking than 304,” says Browning. “It’s generally used by race teams and people who’re building high horsepower turbo systems.” Indeed, 321 stainless is used from NASCAR to Formula One, along with endurance racing, the latter of which perhaps puts the most prolonged stress and heat on the headers.

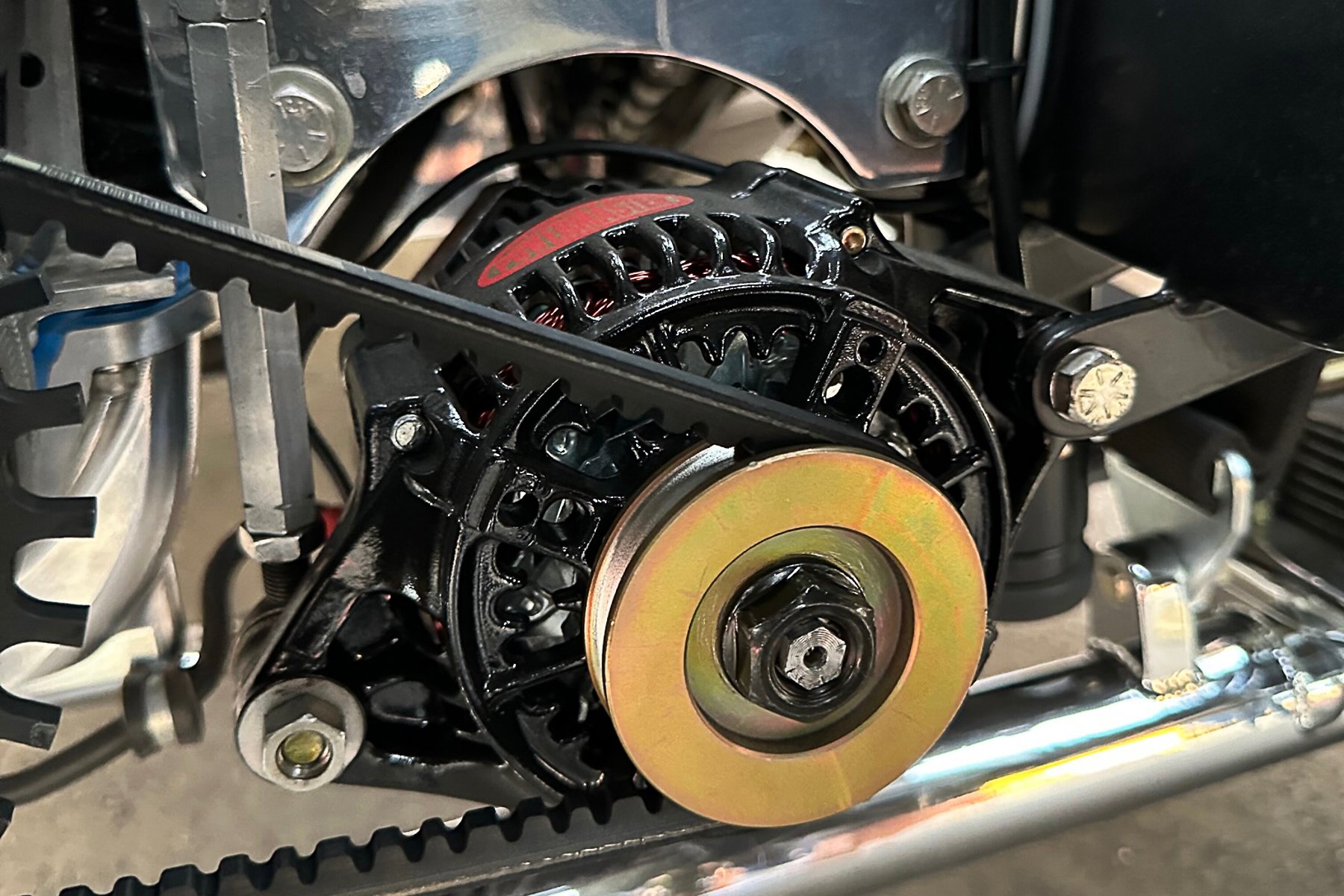

The traditional method of bending tubes to create headers has inherent limitations on their design. It's common practice for the radius of the bend not to exceed the diameter of the tube, as bending the tube any further is likely to cause kinks. Ultimate Headers uses a unique investment casting process that allows them to create tighter radius bends, thereby allowing for tighter packaging. It also allows their tubing walls to maintain uniform thickness from end to end versus the thinning you'll find at bend points on other headers, as seen in the image on the left. Ultimate Headers uses 321 stainless steel for their header tubes due to its ability to withstand heat, while 316 stainless is used for the header flanges. You can find more information about their LS swap header offerings here.

Coatings and Finishes

Ceramic coating has been a popular option from header manufacturers for some time now, as they provide a thermal barrier with the tubing that allows exhaust gas to escape more efficiently and reduce under-hood temperatures while also providing the coating’s aesthetic benefits. Each of the three manufacturers profiled here offers several options for finishes whether coated or uncoated:

- Hooker Headers: Both headers and cast iron manifolds are all available in a ceramic coating with either a polished, black, or titanium colored finish.

- Ultimate Headers: All headers are available with mill, satin, or polished finishes, while ceramic coating is also available in either silver or black.

- Hedman Hedders: All of Hedman’s LS swap headers are available uncoated, with a polished silver ceramic-metallic, or matte black ceramic-metallic coating. These finishes are warrantied for five years.

This is a particular concern near the exhaust ports, where exhaust gases are at their hottest temperature and moving at the highest velocity. The investment casting process not only allows these headers to use a tighter radius bend than the conventional process, it also keeps the tube wall thickness uniform from end to end.

In addition to their LS swap headers, Hooker offers cast iron exhaust manifolds for the job as well. These manifolds take up minimal space in the engine bay and can solves issues that may pop up when a vehicle may be using a different frame, or have ground clearance issues that may limit the use of headers in the build. They are available here in a variety of ceramic coatings that include black, cast iron gray, silver and titanium finishes. Hedman Hedders will also offer a similar cast iron LS swap manifold product, which is due out in December of 2016.

Additional Components

The sum total of parts needed for an LS swap into a vintage chassis varies from vehicle to vehicle, but along with motor mounts, transmission mounts and crossmembers must also be taken into consideration. “In addition to the headers, the most important components to consider for any engine swap are the oil pan, which must clear the crossmember, engine mounts and transmission mounts,” Lewis points out. “They must all be compatible with each other to ensure a properly located and safely installed engine.”

“When we do a swap kit, we don’t just do headers and mounts,” explains Jessee. “For example, our third-gen Camaro swap kit involves headers, mounts, trans crossmember, starter and fuel line heat shields, and a complete stainless exhaust system. We want to offer the customer everything they need in order to do a simple and clean install.”

With so many variables in the equation when it comes to swapping LS power plants into vehicles that were never available with the engine during production, perhaps the most important part of the build is determining what your specific combination entails, as that will help determine the mounts, crossmembers, and headers you'll need to ensure everything will fit and work properly. Between Hedman, Hooker and Ultimate Headers we've covered two distinctly different approaches to the project - the first being a comprehensive conversion kit and the second a header design that works in tighter spaces than conventional headers. Which makes sense for your particular project is something that will probably need to be evaluated on a case-by-case basis.

But some bespoke builds may require a different approach. “Generally our customers know what they have,” Browning told us. “In specific applications there are custom parts that are required. For instance, with LS3 installs into the first-generation Camaro, we offer two different mid-length headers–one set which works with the stock steering box and subframe, and another that’s designed to work with Detroit Speed chassis components, as the driver’s side requires a slight change in the tubing in order to get around the steering box.”

Because of the number of variables involved in the interplay between these various parts, having a clear picture of the combination of components that will be used–both in terms of drive train and chassis–is crucial before selecting headers for the swap to make sure everything will come together properly.

Born at the height of the Malaise Era, this '78 Chevy Malibu was never originally offered with what would be considered a high performance package by most enthusiasts' standards. But with aftermarket support from companies like Hooker Headers, Hedman Hedders, and Ultimate Headers, retrofitting this car with far more grunt (and efficiency) than it ever had from the factory not only possible, but relatively hassle-free.

“For the most part, minimal modification is required, but there may be scenarios where you’ll need to drill holes or massage a transmission tunnel, depending on the vehicle,” Jessee added. “But we design our kits with the intent of the customer being able to do a complete install in his or her driveway or garage in a weekend.”

Be sure to check out the Ultimate Headers, Hooker Headers, and Hedman Hedders websites for all the hardware you’ll need to make your LS swap come together.