Racers and street enthusiasts will soon have an additional option in designing engine combinations when Dart Machinery introduces its LS Next cylinder block at the SEMA Show.

The new block integrates the robust heritage of a traditional Chevy small-block with the performance potential of the late-model LS engine architecture. Available in either high-nickel cast iron or compacted graphite iron (CGI), the block rectifies some of the LS’s more noticeable shortcomings on the bottom end while still supporting the high-flow and efficient cylinder heads developed for the Gen III and IV platforms.

[2]“Our customers have been asking for years why we didn’t make an LS block,” explains Dart’s Jack McInnis. “We’ve made a billet racing version but not a cast version. We looked at a number of design possibilities, and we feel this is the best option.”

[2]“Our customers have been asking for years why we didn’t make an LS block,” explains Dart’s Jack McInnis. “We’ve made a billet racing version but not a cast version. We looked at a number of design possibilities, and we feel this is the best option.”

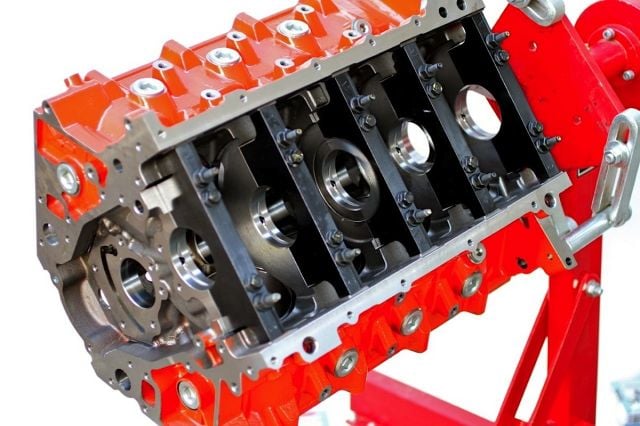

Dart’s hesitancy to launch a cast-block program first centered on production concerns, but of more importance to the eventual performance customer was the original LS deep-skirt crankcase design that includes 6-bolt, cross-drilled mains. The crankshaft bays are isolated from each other, which can result in unwanted windage issues.

“This causes a loss of power in performance applications when the oil gets whipped up around the crank,” stresses McInnis.

To solve the problem, Dart drew inspiration from the original Chevy small-block by replacing the LS “Y” block construction with a traditional Chevy crankcase design and beefy 4-bolt main caps, which can be ductile iron or steel. The outer bolts are splayed on caps #2, #3 and #4. The blocks feature full main webbing for increased bottom-end strength, and 7/16-inch main-cap bolts are used.

Here's are cross-sectional and actual views of the deep-skirt, 6-bolt cross-drilled mains found on the LS platform.

Even though the crankcase rails were fashioned with traditional Chevy logic, oil pans specific to this block will be needed. Dart will be meeting with popular aftermarket oil-pan manufacturers to develop the needed applications for late-model vehicles, vintage musclecars and race vehicles. Custom pans will also allow for larger capacity, full-sump pans, or customers can still opt for a dry-sump system.

“The block also features both Gen I and Gen III styles of motor mounts,” says McInnis, which will help facilitate engine swaps into a variety of vehicles. The block also has starter mounts on both sides, again smoothing the way for installation in different applications.

- Construction: Gray Iron 220 BHN or 270 CGI up to 270 BHN

- Deck height: 9.240 inch

- Cylinder-barrel length increased .375-inch over stock

- Cylinder bore: 4.000 or 4.125 inch

- Max stroke: 4.100 inch

- Cam bore: Standard LS, 60mm babbitt, 55mm roller

- Main bearings: Standard LS w/ revised top shell

- Main caps: 4-bolt ductile iron or steel

- Rear main seal: Stock one-piece

- Lifter bore: Standard .842 inch, optional .937-inch keyed

- Oiling: True priority mains; wet or dry sump

Dart set the deck height at 9.240 inches with a full 5/8-inch-thick deck. The GM LSX cast-iron block comes in either semi-finished 9.260- or 9.700-inch deck heights. Dart does not offer a tall-deck version at this time but has implemented design upgrades to support a crankshaft stroke up to 4.100-inches.

“We increased the cylinder barrel length .375-inch over stock,” explains McInnis. “This gives the effective equivalent of a taller 9.615-inch deck in terms of supporting piston travel. It also allows better piston designs for stability.”

Customers can order either a 4.000- or 4.125-inch bore, and the Siamese cylinders can be safely bored to 4.200 inch. Dart also increased the head-bolt size to 7/16-inch, and the head-bolt holes are blind — meaning they don’t extend into the water jackets. The standard six-bolt-per-cylinder head pattern is retained.

Although a stock LS oil pump can be used, Dart made extensive revisions to the oil system. The stock internal main oil galley was replaced with a low-restriction priority main oiling system. The Pro Stock style main galley is stepped — 9/16 to 1/2 to 7/16 inch — to allow more volume without a loss of pressure at the front of the block. Also, there are now provisions for oil restrictors in the lifter valley.

“You will have to use an external oil filter,” says McInnis, “but you can use one larger than stock.”

Additional features of the LS Next block include extended water jacket on the #1 cylinder for improved cooling, LSX-style lifter bosses and dogbone provisions are provided and the standard cam bores can be increased to accommodate 60mm babbit or 55mm roller bearings.

Dart will release pricing at a later date.