[1]Lingenfelter Performance Engineering [2] is a household name among automotive enthusiasts and have been offering engine builds, engine components, engine calibration, and chassis tuning components for a large variety of GM vehicles.

[1]Lingenfelter Performance Engineering [2] is a household name among automotive enthusiasts and have been offering engine builds, engine components, engine calibration, and chassis tuning components for a large variety of GM vehicles.

At the 2016 SEMA Show, we stopped by the Lingenfelter booth and met Jason Haines, project director of LPE, who gave us the lowdown on what new products Lingenfelter has in store for the GM Gen V crowd.

Haines was quick to show us LPE’s new high-flow fuel system and camshaft kit for boosted or E85 converted Gen V engines (L700046914 [3]), such as the LT1, LT4, L83 and L86. “We now offer a new high-flowing direct-injection fuel injector, fuel pump and camshaft kit for the newer GM Gen V engines,” says Haines. “Now turbocharged, supercharged or E85 conversion Gen V owners can get the fuel delivery they need without having to incorporate secondary fuel injectors and all of the complexities that come along with that.”

“A stock set of direct injection LT4 fuel injectors will typically see about 17 g/s [135 lb/hr] on a flow bench and will quickly reach ‘max’ duty cycle with very few modifications,” states Haines. “On your average port injection engine you basically have the entire pulse width range to work with up to 19 ms, because the intake valve controls the timing of fuel delivery into the combustion chamber. For direct-injection injectors, you will rarely make it above 6 to 6.5 ms before you start seeing misfires.”

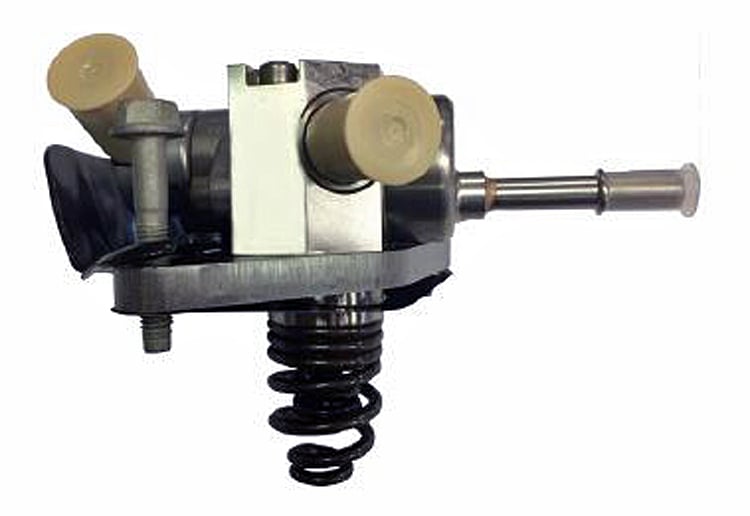

“Our new direct-injection injectors included in this kit flow at 22 g/s [175 lb/hr], are precision flow-matched for better control of your fuel delivery across each cylinder, and we partnered with Nostrum Energy to include their exclusive K-DI kinetic injector nozzle for optimal fuel atomization,” explains Haines. “When you combine our 22 g/s fuel injectors with the included 12.0 mm bore direct-injection fuel pump and our 6.5 mm fuel pump lobe GT35 camshaft, this kit pushes 50-percent more fuel than a stock LT1 and about 20-percent more than a stock LT4.”

Left: Lingenfelter's GT35 camshaft, with a 6.5 mm fuel pump lobe. Right: High flow 12.0 mm bore fuel pump.

According to Haines, LPE dyno tested this high pressure fuel system on a twin-turbo LT4 and noted fuel delivery capable of supporting peak power numbers of over 1,100 horsepower on pump gas and 900 horsepower on E85, with an injector pulse width of just 5.0 ms.