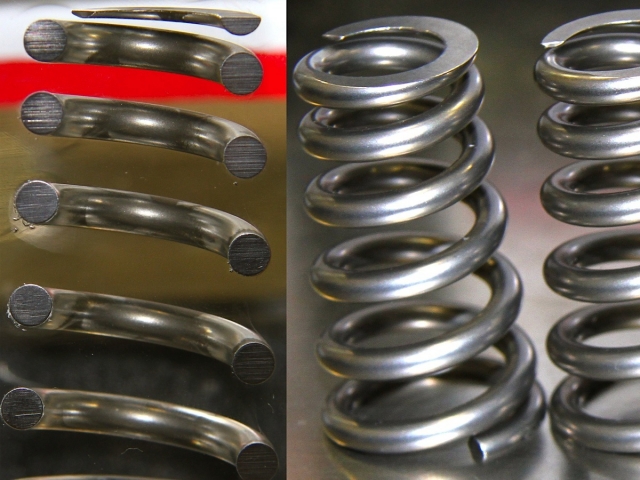

“So, how do you get excited about valve springs?” asks Comp Cams [1]‘ Trent Goodwin.

Basically, you reinvent them with a clever conical shape that promotes a progressive natural frequency design.

“The smaller top end reduces mass,” explains Goodwin. “Also, we developed a new material special to this spring design.”

The new design helps increase the valvetrain rpm limits while reducing resonance concerns and decreasing dynamic spring oscillations. The latter payoff is especially comforting to any racer whose seen slow-motion video of valve spring in action on a high-lift engine. It gets rather ugly.

“You’ll get longer spring life and still run cams with a more aggressive lobe,” adds Goodwin, noting that the conical design promotes damping with less less wear, heat and friction. The round wire construction is also treated to a “superfinish” surface process that helps handle the demands of high-lift cams and also boosts spring life.

Three part numbers are currently available:

- #7228: 1.290 bottom OD, 1.020 top OD; 438 lbs/in rate

- #7230: 1.332 bottom OD, 1.060 top OD; 520 lbs/in rate

- #7256: 1.390 bottom OD, 1.060 top OD; 485 lbs/in rate

Early applications will focus on the GM LS and LT engines.

Speaking of the LT engine family, Comp Cams also announced the release of new bumpsticks for the LT1/L83/L86 engines in both street performance and sportsman racer designs. The street cams are designed to work with the direct injection, variable valve timing and AFM features of the Gen V architecture. Four lobe profiles are available, and the cams require Comp’s Phaser Limiter Kit — which limits the range of cam timing adjustment from 62 to 22 crank degrees. That also means the VVT tuning must be adjusted. Applications include the new GM trucks and the Gen 7 Corvette. A fifth non-AFM profile is also available.

In addition, Comp offers a Gen V Sportsman Tool Steel camshaft. Tool steel is 30 percent stronger than the SAE 5150 or SAE 8620 cam cores typically used in LS engines. Tool steel allows the use of more aggressive profiles on both the DI lobe as well as the cam lobes. The cams are available with or without AFM compatibility.

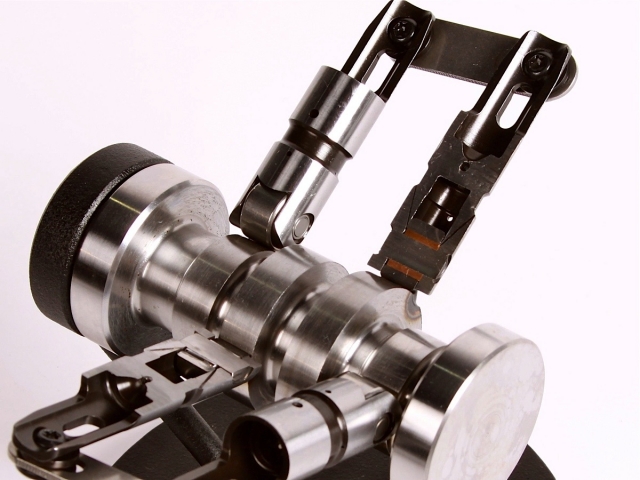

Finally, Comp Cams is releasing a new line of Sportsman solid roller lifters.

“With these lifters, the engine builder has a choice of needle bearings or bushing,” says Goodwin. “They’re a lighter upgrade from the Endure-X line but still a value alternative to the Elite Race lifters.”

Each model is lubricated with two pressurized EDM oil feeds and an edge-orifice feed to the wheel. Construction is from premium 8620 alloy steel, and there’s a tapered and slotted link-bar tower for reduced weight. Also, the body utilizes a skirted wheel that strengthens the lifter ears, and the skirt is designed to provide more contact area with the lifter bore for improved stabilization. Applications include BBC, SBC, SBF and big-block Chrysler/Hemi.