[1]Snap-On is well known by auto enthusiasts for their common hand tools but shops and high performance teams realize that Snap-On provides substantial test equipment as well. At this year’s SEMA Show in Las Vegas, Nevada, we checked out their Integrity Test Drive System by John Beam.

[1]Snap-On is well known by auto enthusiasts for their common hand tools but shops and high performance teams realize that Snap-On provides substantial test equipment as well. At this year’s SEMA Show in Las Vegas, Nevada, we checked out their Integrity Test Drive System by John Beam.

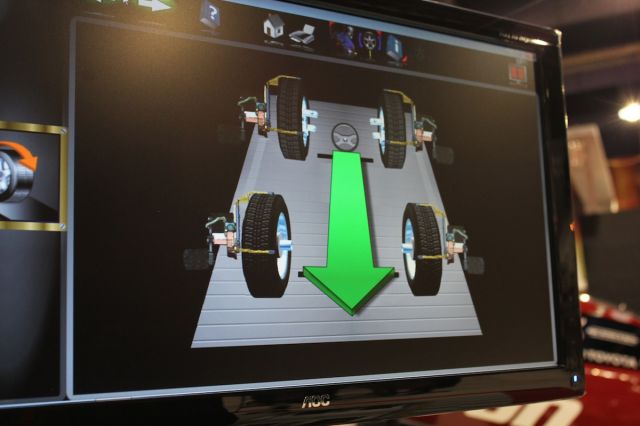

Snap-On’s Greg Libertini explains the system,”The integrity test drive system performs a vehicle inspection that includes alignment, battery, brake efficiency, brake pad thickness and diagnostic codes, then reports the results of each inspection.”

While the key component of the system is the alignment audit, the dynamic brake audit system has to be considered a very well thought out addition to the complete package. Able to inspect brake performance in less than a minute, the inspection checks the brakes clamping force, brake generated pulls and brake bias. Other common areas of brake maintenance, like runout and pulsation are also checked.

The alignment audit is also performed in under a minute. Detecting worn suspension components, along with alignment specifications, the system provides a complete print-out of alignment measurements and summary of measurements against the manufacturer’s specifications.

- Multiple languages

- VIN reader

- Cross diagonal

- Camber

- Front and rear toe

- Track width

- Rolling radius

- No lift required

- Charging system test

- Cable voltage drop test

- USB and Infrared connectivity

- Class 1 Bluetooth wireless technology

- Touch screen operation

- 2-megapixel camera

- External SDHC card slot

- Digital video recording

- Digital still image capturing