If you have ever owned a car with a cable driven clutch, you know how much fun they aren’t – they require constant adjusting and can be a bare to press down. Though if you also installed an improperly engineered hydraulic conversion kit, the clutch turns into an on/off switch. The key to a perfectly-functioning hydraulic clutch comes down to two words – pedal ratio.

[1]

[1]

Pairing with a Hydraulic Bearing

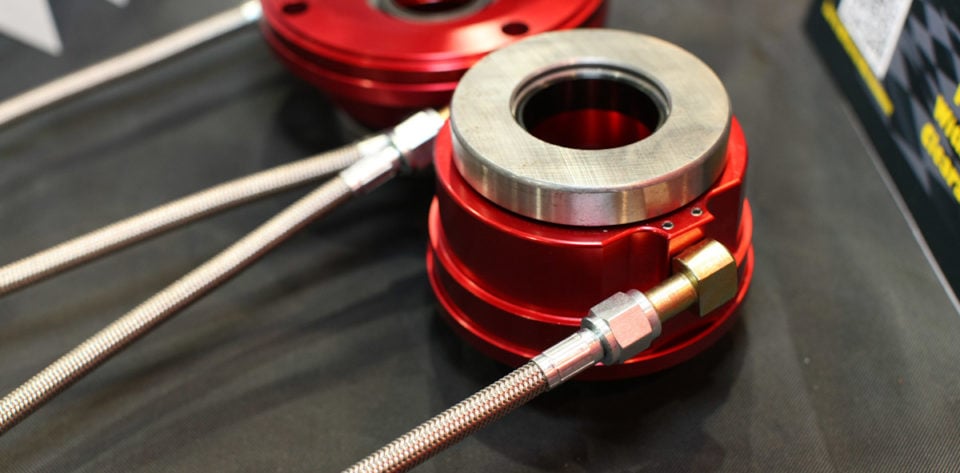

To complete your hydraulic clutch conversion, McLeod offers a hydraulic release bearing in two styles. The first (pictured right) slips over the driveshaft’s collar and is height adjustable. The second (left) replaces the actual collar and standoff height must be specified before ordering.

McLeod understands these special two words, which is one of their primary goals when it comes to developing a hydraulic clutch application. The other? Ease of installation. “I engineer all our hydraulic clutch kits from the customer’s point of view,” said Fred Taylor of McLeod. “I try to make them as dummy proof as possible.”

If you have ever driven on a vehicle with an improperly designed hydraulic clutch kit, you will know that they function as a light switch. This is due to an improper pedal ratio. Mcleod goes to great lengths to make sure that your pedal travels the same as stock, thus giving you stock-like engagement with less strain.

Currently available for 1955-57 Chevy Bel Air, 1967-69 Camaro, 1968-74 Nova, and a variety of Mustang generations, Mcleod has come up with two different kits – the full complete kit and the firewall kit. “A complete kit comes with the master cylinder, internal or external hydraulic slave cylinder, mounting brackets, remote reservoir and all necessary mounting hardware,” said Taylor. “The firewall kit will offer everything listed in the complete kit minus the slave cylinder.”