In the interest of total disclosure, before we get into Dynojet’s [1] 2012 SEMA offerings, we have a confession to make; at Power Automedia, we have an in-house Dynojet 424 chassis dyno, so you might say we have a bit of a bias. It’s been an editorial testing workhorse, gauging the output of everything from 100-horse econobox commuter cars to our 8-second drag radial race car.

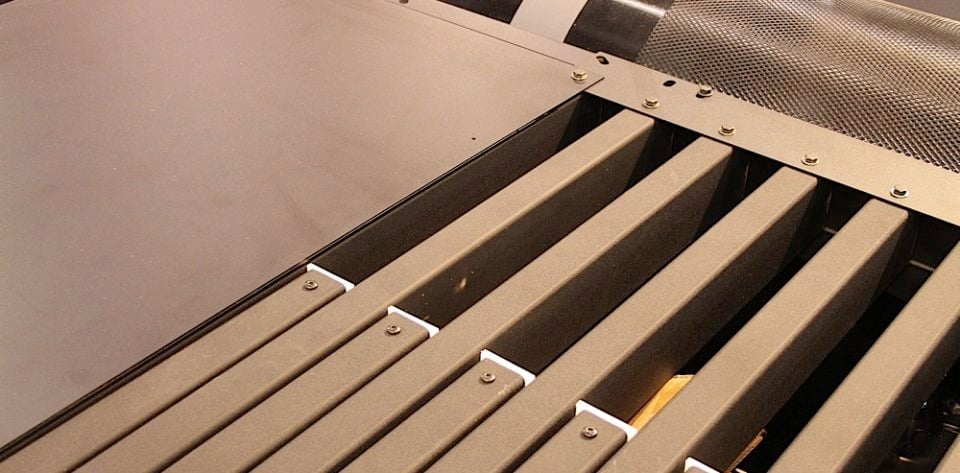

With that said, we were eager to see what’s new at Dynojet, because one of the great things about their chassis dynos is that they’re upgradeable. Start with a basic 224X two wheel inertial dyno, and you can test any front or rear wheel drive car, up to 2000 horsepower and 200 miles an hour. When you need to do constant load testing for in-depth tuning, you can convert your 224X to 224xLC spec by adding an eddy current load module, or if you want to step up to all-wheel dyno testing, a second drum unit and the power adjustable deck system will turn your 224 into a 424.

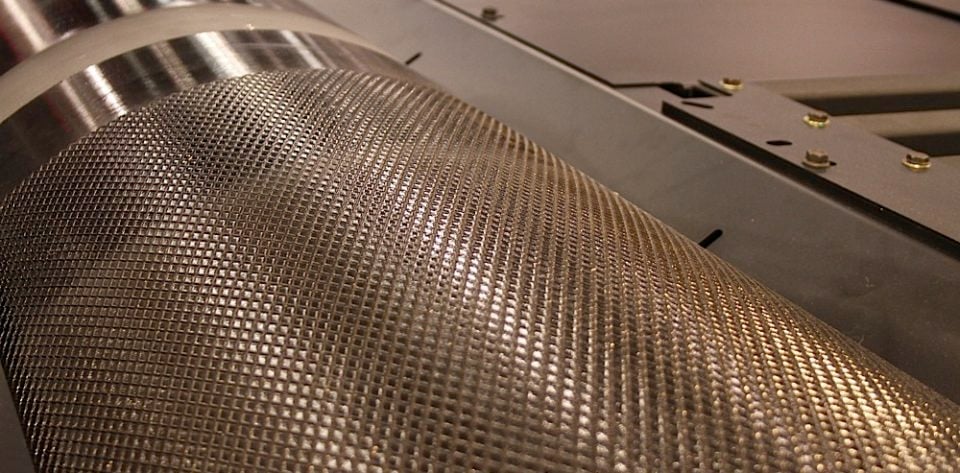

Dynojet's large, single roller inertia drums have a knurled surface for a very high coefficient of friction. The 4-wheel 424x platform power-adjusts to accommodate various wheelbase vehicles.

For the ultimate Dynojet, you can upgrade all the way to the 424xLC2 with Linx, as shown here. It features dual eddy current load absorbers, adjustable wheelbase all-wheel-drive capability, and the Linx system that mechanically synchronizes the drums. For testing sophisticated all-wheel-drive automobiles that can have problems with, or even be damaged by unsynchronized AWD dynos, or even 2WD cars that enter “reduced power” mode when front and rear wheel speeds differ, there’s just no substitute.

Yes, we’re a little biased. But when you use a tool every day and it never lets you down, you tend to believe in it…