[1]Performance brakes are a big sector in the automotive aftermarket. Competitors volley back and forth with offerings of increasingly gigantic rotors, bulbous calipers containing hitherto unknown amounts of pistons, and grabby compounds to comprise the friction material in their race pads.

[1]Performance brakes are a big sector in the automotive aftermarket. Competitors volley back and forth with offerings of increasingly gigantic rotors, bulbous calipers containing hitherto unknown amounts of pistons, and grabby compounds to comprise the friction material in their race pads.

Performance Friction Brakes (PFC) [2] of course brings to market the products consumers demand in terms of applications and sizes, but focuses more on weight savings than most manufacturers.

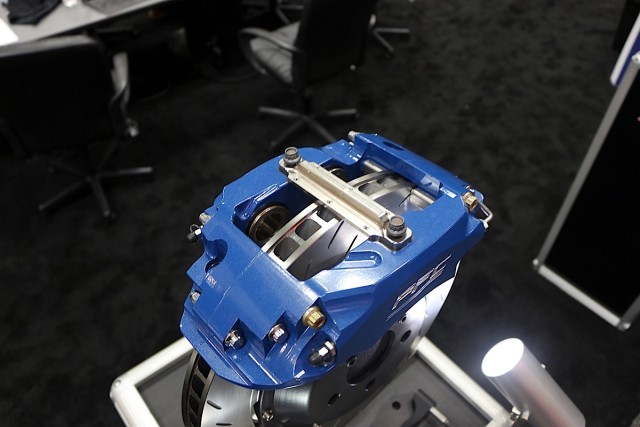

This year at PRI, PFC had several new innovations to share for both the racing and street markets. On display in the booth was a Porsche GT3R race car wearing its new V3 series brake system. The features of the V3 are two-fold in that they revamp both caliper and rotor for uncompromising performance.

[6]In order to maximize every bit of power and prevent brake drag from generating parasitic losses to the momentum of the vehicle, PFC has integrated their pad retraction system. Removing drag and lowering operating temperatures with this feature helps the performance and lifespan of the braking system.

[6]In order to maximize every bit of power and prevent brake drag from generating parasitic losses to the momentum of the vehicle, PFC has integrated their pad retraction system. Removing drag and lowering operating temperatures with this feature helps the performance and lifespan of the braking system.

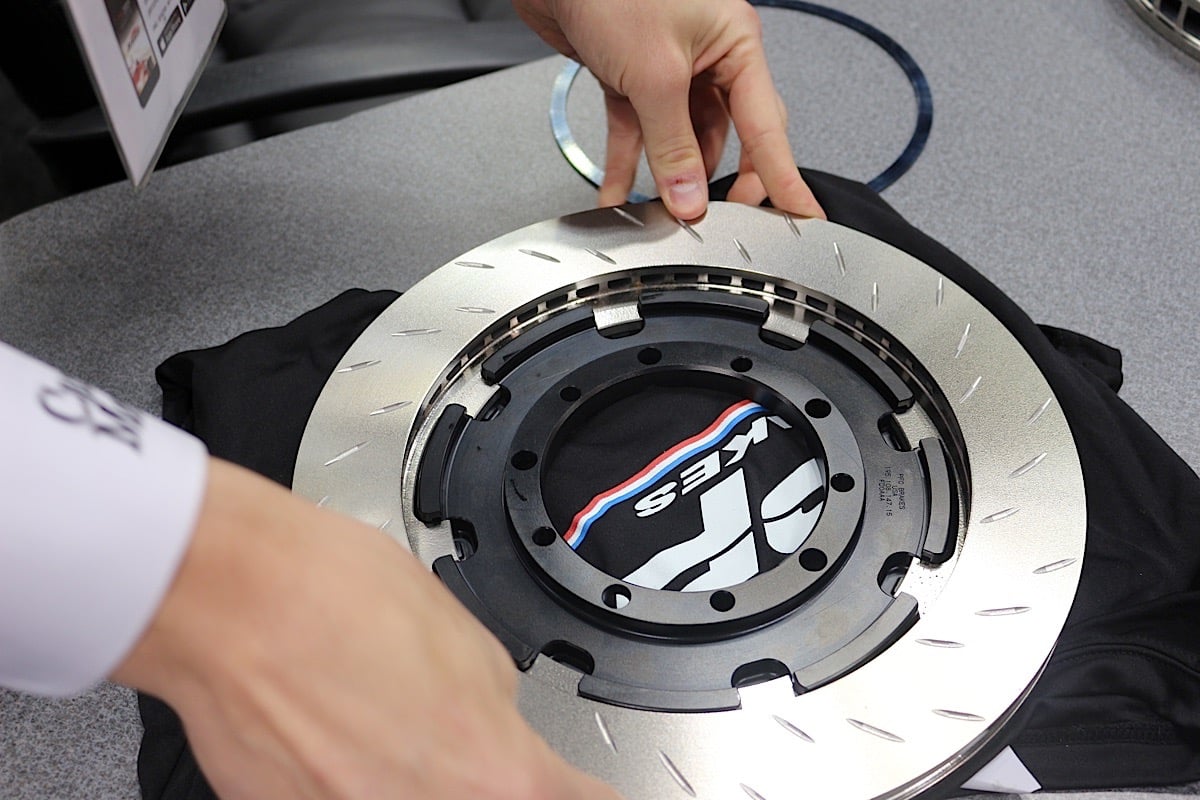

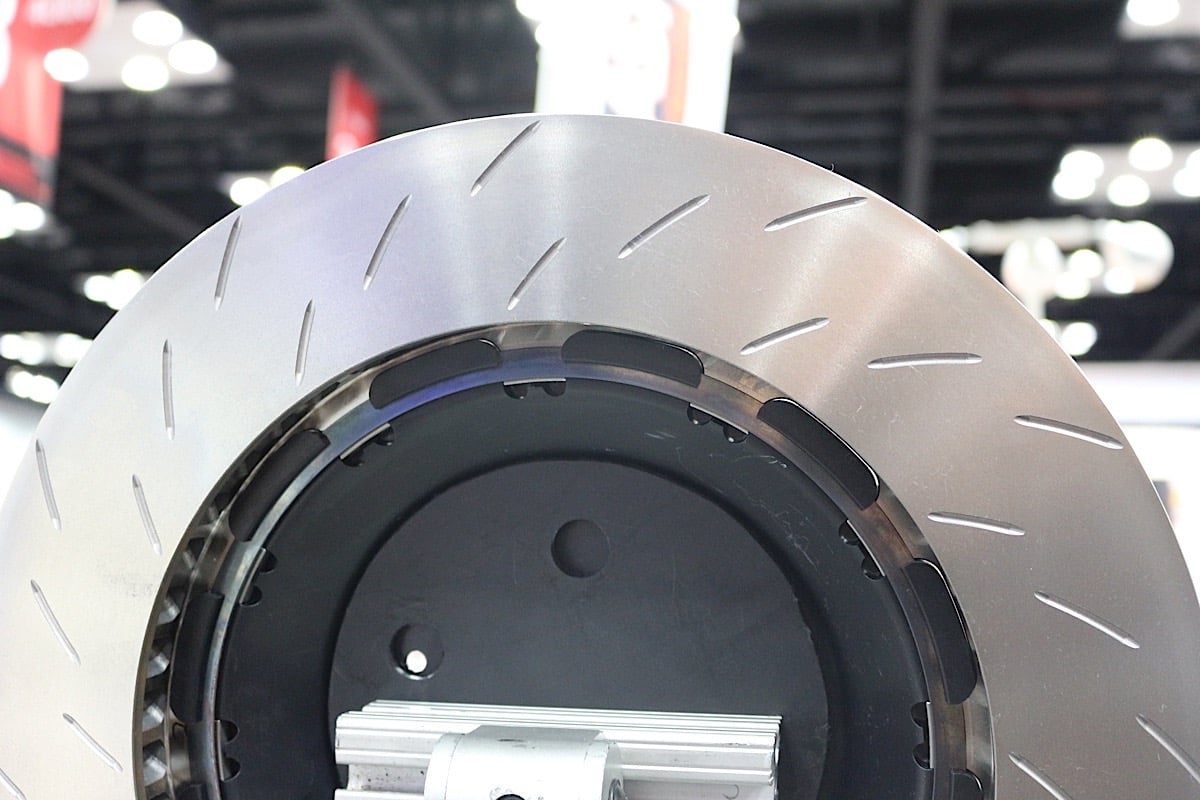

The second feature of the V3 system is a new fastening system to join the rotor and hat. In PFC V3 floating rotors no traditional hardware is utilized to fasten the components, instead, a giant Spiralock ring like that found retaining a wrist pin, is used to make the connection.

The removal of hardware on the outer extremity of the rotor hat reduces the total weight a whopping 1.3 pounds per corner! With a reduction like that unsprung weight and rotational inertia will be favorably improved.

The V3 system will be available for both both foreign and domestic muscle, so keep your eyes peeled for PFC brakes becoming available for your application.