At the SEMA show Dart Heads [1] released their brand new LS block [2], the first of it’s kind from Dart. “Four years ago we looked at producing an LS-based engine and decided against it, only releasing a billet version,” said Jack McInnis of Dart. “Not until around July did we look at producing this block again, coming up with our redesigned LS Next engine block.”

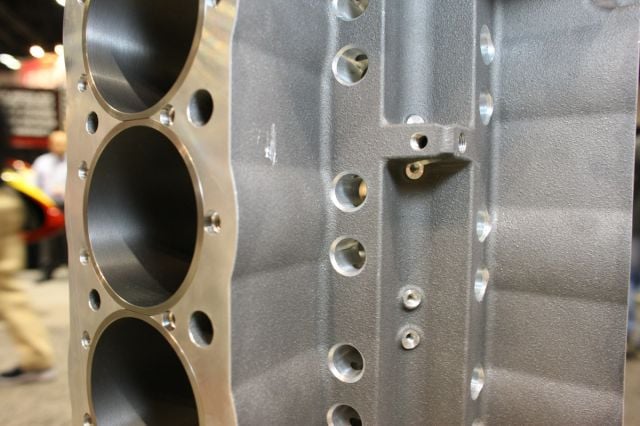

[3]For those of you that are keen to the LS block’s infrastructure, you will notice that the bottom of the block – near the main caps – is missing a whole section of metal, traditionally called the Y-block design. Dart has decided to eliminate this entire area to enhance the casting quality.

[3]For those of you that are keen to the LS block’s infrastructure, you will notice that the bottom of the block – near the main caps – is missing a whole section of metal, traditionally called the Y-block design. Dart has decided to eliminate this entire area to enhance the casting quality.

What you see here now resembles what you would find on a Gen I block. “Due to this redesign, you will need a custom oil pan in which many of the popular aftermarket companies will produce,” said McInnis. Also by recessing the pan rails has naturally increased the ability to hold more oil in an overall same, complete package.

Redesigned Small Block Chevy and Ford Aluminum Blocks

For the PRI show, Dart has their updated aluminum small block Chevy and small block Ford engine blocks. Both blocks start with an overall cleaner-poured casting, explains Jack McInnis of Dart, “We started back at the foundry by redesigning the tooling to produce a cleaner, better looking casting right out of the gate. But outside of the new casting, there are a lot of new, great features as well.”

Small Block Chevy

Small Block Ford

The small block Chevy block received the lion share of the upgrades. The cylinder barrels have been extended to offer better piston support on longer stroke combinations while deck heights range from 8.850″ to 9.500″. That combined with the .391″ (with optional .434) raised cam could make a 450ci+ small block a reality.

Big block camshaft bearings allow the use of cams with larger base circle diameter to improve strength and reduce twisting with cam-driven pumps. The lifter valley has also been redesigned in aiding of moving around lifters (.842″ standard) to achieve proper geometry.