Nearly 130 years have passed since the first automobile was available. According to Wikipedia, “In 1886 the first petrol or gasoline powered auto-mobile the Benz Patent-Motorwagen was invented by Karl Benz. This is also considered to be the first ‘production’ vehicle as Benz made several identical copies.”

You don’t have to be a car fanatic to realize we have come great lengths from those original, relatively crude methods of transportation. That being said, we thought we should take a look at five different technologies we think have helped to propel America’s sports car into what it is today.

Independent Rear Suspension

The first Corvettes were built with roughly the same style of rear suspension as many muscle cars and trucks: a solid rear axle, also known as a live axle, supported by leaf springs. While this can make for a strong, reliable choice that can be built to handle extreme power and loads, it is not the first choice for a sports car.

Corvette engineers quickly became aware of its shortcomings and opted to begin producing their own version of what is commonly referred to as an IRS system, or Independent Rear Suspension. Released in 1963, IRS systems were first bolted under the gorgeous C2 split-window and would continue with the chassis for years to come.

The beauty of an IRS for sporting applications, amongst others, is that it allows the rear wheels to move independently of one another, much like the independent A-arms found in many front suspensions. Not only does this increase handling and cornering ability, but it adds an immense amount of suspension tuning unavailable with the live axle.

Along with the independent rear axles came a new way to spring the rear section of the Corvette as well. Since the Hotchkiss style suspension (a traditional leaf spring setup in which the leaf springs acts as an arm or link to maintain the position of the live axle) had been removed, the engineers were looking for something a bit more cutting-edge. There are several other common methods for springing sports cars, and they generally all have their advantages and disadvantages.

That being said, the Corvette was designed with a suspension type known as a transverse leaf spring. You can effectively think of it as a single leaf spring, not unlike those discussed above, turned 90 degrees, and constructed in a manner stiff enough to support the car with one leaf. Since the car does not rely on this piece to act as an arm or link as well, it purely serves the purpose of a spring, much like a coil spring application.

The transverse leaf was constructed of an extremely strong recipe of fiberglass and other composites in order to achieve the correct combination of strength and flexibility. Some could argue that it was ahead of its time, and perhaps that was the case as this transverse leaf is still used in every Corvette made today, over 50 years later.

Magnetic Ride Control

Some of you may be familiar with the Porsche 959 of the 1980s. Well, love them or hate them, and odds are it’s the latter for diehard Corvette fans, it was equipped with a very special suspension technology which can also be found on the 1989 Corvette ZR-1.

Initially, Bilstein had designed an electronically adjustable suspension system for the Porsche. While the 959s were equipped with the technology, there was a limited market for Bilstein as there were very few 959s built for sale. Supposedly, it cost Bilstein about $230,000, nearly a half million dollars in today’s market.

Initially, Bilstein had designed an electronically adjustable suspension system for the Porsche. While the 959s were equipped with the technology, there was a limited market for Bilstein as there were very few 959s built for sale. Supposedly, it cost Bilstein about $230,000, nearly a half million dollars in today’s market.

Bilstein was already supplying standard gas shock absorbers to Chevrolet for all C4 applications, so in an effort to profit further on their technology, a deal was created for Chevy’s high-performance project, the ZR-1.

Ultimately, the same technology used on the 959 was brought to the Corvette and recalibrated to work with the C4’s specifications. The driver of every ZR-1 now had the ability to adjust the ride characteristics on the fly to match their desires. The car could be set to ride more smoothly for casual driving, very stiff for racing applications, and somewhere in between for times of spirited driving.

Ultimately, the same technology used on the 959 was brought to the Corvette and recalibrated to work with the C4’s specifications. The driver of every ZR-1 now had the ability to adjust the ride characteristics on the fly to match their desires. The car could be set to ride more smoothly for casual driving, very stiff for racing applications, and somewhere in between for times of spirited driving.

While magnetic ride control has received some refinement over the years, the technology was revolutionary for its time and is still available on the C7 Z06 supercars of today.

The Transaxle

At this point, the Corvette was riding on a pair of transverse mounted leaf springs with four-wheel independent suspension, and even had the ability to change ride quality and characteristics on the fly.

“So what’s next?” the engineers may have been pondering in front of the proverbial drawing board. Well, those of us more familiar with what makes great sports cars great, know that a proper weight distribution is rather crucial.

“So what’s next?” the engineers may have been pondering in front of the proverbial drawing board. Well, those of us more familiar with what makes great sports cars great, know that a proper weight distribution is rather crucial.

Thus, to better balance the new Corvette, the GM team decided to ditch the traditional transmission and replace it with a rear-mounted transaxle.

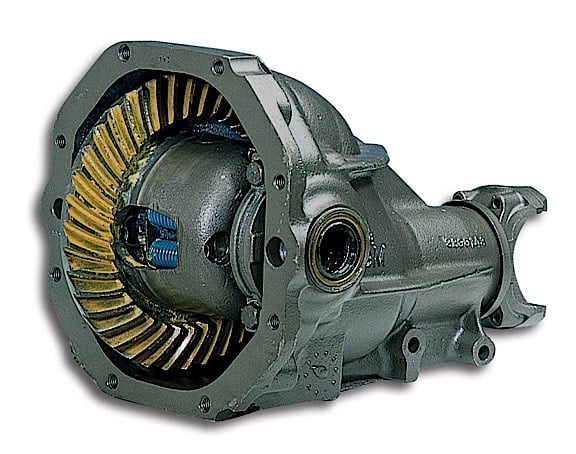

Simply put, a transaxle combines the components of a transmission–manual or automatic apply–the differential, and the remaining associated parts into one main assembly. Not only does this save space and weight overall, it moves some of that weight to the rear end of a car. Additionally, this provides space for the engine to be moved slightly rearward, again striving towards a 50/50 weight distribution.

Not only was the Vette beginning to balance itself out,but there was also more power to be had in store for America’s sports car, and it would continue to need consistent, reliable means of getting that power to the ground. The transaxle designs would continue to prove themselves worthy all the way through the thunderous power of the C7 Z06.

Engine Platforms

The first engine that the Corvette received was the Blue Flame 150, which was a 235 cubic-inch, 3.9-liter, inline six-cylinder that produced about 155 hp. Everyone starts somewhere, and for America’s sports car, that was it. However, the desire for more horsepower had a 4.3-liter 265 cubic inch V8 in place of the Blue Flame rather quickly, which produced a much more impressive 195 hp for the remaining 1955 cars, followed by 210 hp and 240 hp for the 1956 and ’57 model years respectively.

While this was a noticeable step up in performance, it would still be underpowered when compared to the other top-tier sports cars that the world had to offer. Jerry Earl, the son of Harvey Earl, was involved in road racing in the time of the first-gen Corvettes, hence the SR-2.

While this was a noticeable step up in performance, it would still be underpowered when compared to the other top-tier sports cars that the world had to offer. Jerry Earl, the son of Harvey Earl, was involved in road racing in the time of the first-gen Corvettes, hence the SR-2.

Even with a high-powered 283 cubic inch V8, one of the first critiques the Corvette team had was that they would need more power to really be competitive. Thanks in part to Smokey Yunick, the race cars soon sported the Rochester mechanical fuel injection and larger displacement engines.

While leaps and bounds were made during these years in engine performance, it wouldn’t be the last time the Corvette stood on the front lines for engine development.

The LT5

In 1990, Chevrolet brought the Corvette ZR-1 to market. For the majority of its life, Corvettes had been synonymous with pushrod V8s. This time, Corvette went another route and decided to give the overhead cam trend a try. Acknowledging any shortcomings they may have had in the new field, GM enlisted the help of Lotus Engineering in the UK for the design. The production was carried out by Mercury Marine.

In 1990, Chevrolet brought the Corvette ZR-1 to market. For the majority of its life, Corvettes had been synonymous with pushrod V8s. This time, Corvette went another route and decided to give the overhead cam trend a try. Acknowledging any shortcomings they may have had in the new field, GM enlisted the help of Lotus Engineering in the UK for the design. The production was carried out by Mercury Marine.

The new mill was an all-aluminum 5.7-liter small-block V8, with 32-valve DOHC (Dual Over Head Cam) heads. In the beginning, the motor produced about 375 hp but was eventually increased to 405 hp for the 1993-1995 cars. The increase in power was achieved by improvements to cam timing and engine porting. A four-bolt main was also in 1993 along with an EGR (Exhaust Gas Recirculation) system.

The 32-valve monster may have been relatively short-lived for Corvette, but for those of you who were fans of Cadillac’s aluminum DOHC V8–dubbed the V8 Northstar–in part, you can thank the LT5.

The Birth Of The LS

The LT line of engines was certainly nothing to shake a stick at, but Corvette knew that the times were changing, and America’s sports car needed a new powerplant to stand on. While there would ultimately be more versions than you can count on one hand, the LS1 would make it shining debut in 1997 strapped inside of the first C5 Corvette.

The LT line of engines was certainly nothing to shake a stick at, but Corvette knew that the times were changing, and America’s sports car needed a new powerplant to stand on. While there would ultimately be more versions than you can count on one hand, the LS1 would make it shining debut in 1997 strapped inside of the first C5 Corvette.

The motor initially produced 345 hp and 350 lb-ft of torque, and this was only the beginning. There were many great changes and designs in the LS series, which would ultimately come to a close for Corvettes with the LS9 in the ZR1 C6. This motor was based off of the LS3 due to thicker sidewall construction when compared to the LS7, and produced a whopping 638 hp and 604 lb-ft of torque.

A LT For A New Era

You may have noticed by this point that GM most commonly uses its flagship, the Corvette, to introduce the newest automotive technologies to the public. When the C7 Stingray was released it harbored an all-new engine family, with a designation from the past; the LT1.

You may have noticed by this point that GM most commonly uses its flagship, the Corvette, to introduce the newest automotive technologies to the public. When the C7 Stingray was released it harbored an all-new engine family, with a designation from the past; the LT1.

While there is a list of technical data to be discussed about the new LT1, the huge “first” for GM is the use of direct injection. For those unfamiliar, direct injection takes highly pressurized gasoline and injects it directly into the combustion chamber, similar to the way a diesel engine operates. This is in contrast to conventional fuel injection in which the fuel is injected somewhere along the intake tract or intake port. There is certainly an increase in complexity here, but there is something to be said about 460 hp.

The C7 Z06 would receive a similar engine, named the LT4 which utilized forced induction thanks to a supercharger. While the designs are relatively similar, the LT4 is constructed with a serious dose of strong equipment as it produces a face-melting 650 hp and 650 lb-ft of torque. They are quite the ride!

Frames Go Lighter and Stiffer

While the shape, weight, and construction methods of the Corvette frames would change drastically from the first generation on through the fifth generation, the overall concept remained relatively the same–a steel ladder-type frame.

There was certainly a leap in technology made when constructing the C5 frame, as a new construction process was utilized for the first time. In an effort to eliminate welding of the frame rails, sections of tubing were closed off at each end, filled with extremely high-pressure water and formed into the desired shape, the process would be known as hydroforming.

There was certainly a leap in technology made when constructing the C5 frame, as a new construction process was utilized for the first time. In an effort to eliminate welding of the frame rails, sections of tubing were closed off at each end, filled with extremely high-pressure water and formed into the desired shape, the process would be known as hydroforming.

When the convertible was released the following year in 1998, the new frame was so rigid that the engineering team was able to forego the usual stiffening components generally associated with a convertible’s design and increased weight when compared to a coupe.

This frame technology would last for years, but when the Corvette team began designing the C6 Z06, they knew it was time for something more. While the car’s exterior would look fairly similar to the standard C6, it would be built on a platform more suited for Nurburgring.

The Z06 received a never-before-seen aluminum chassis which increased rigidity and decreased weight. This frame construction was only available for the Z06 and ZR1 platforms for the sixth-gen Corvettes. However, both the base model Stingray and the Z06 were constructed with an aluminum chassis in the later C7 configurations.

When the all new 2014 C7 Stingray was first released, Chevrolet advertised that the aluminum chassis reduced weight by 99 pounds, and increased stiffness by 60-percent when compared to the C6 coupe.

A Leader In Innovation

Whether it be engines, frame and spring materials, or electronically controlled handling adjustments, the Corvette has been a tool of innovation, performance, and speed since its inception in 1953.

While we should never stop enjoying the vehicles of our past, you can’t help but wonder and imagine what the next generation of Corvettes will introduce us to. Will there be an entirely new family of engines, or a composite frame free of all metals? Only time will tell, so in the mean time, keep on enjoying over 60 years of technology and innovation with America’s sports car.